Equipment for producing cuprum-cladding-aluminium composite wire

A composite wire, copper-clad aluminum technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high product cost, low total processing rate, reduced yield and conductive efficiency, etc., to achieve high production efficiency, The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be described below in conjunction with the drawings.

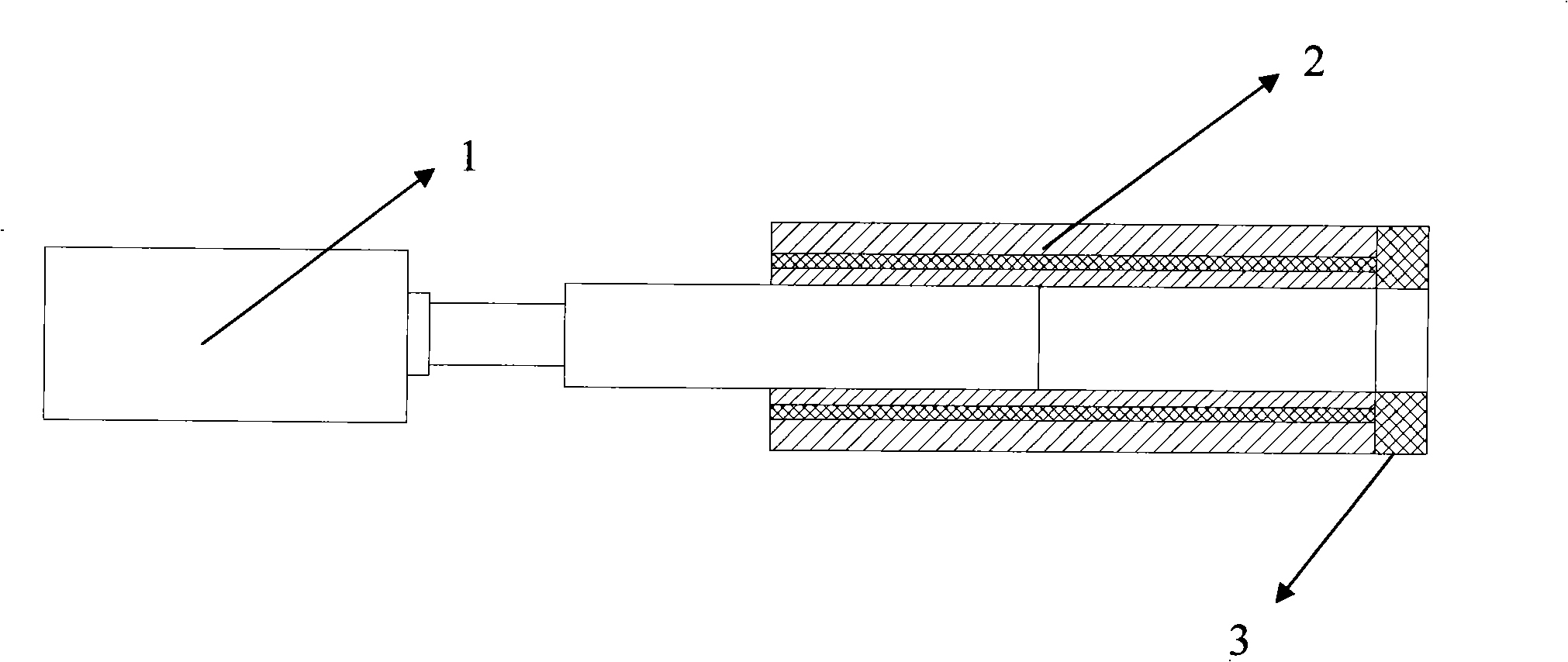

[0009] Such as figure 1 As shown, an equipment for preparing copper-clad aluminum composite wire is provided with a horizontal hydraulic drive device 1. The hydraulic drive device includes a hydraulic cylinder. A tubular fixing frame 2 is arranged in the direction of the output shaft of the hydraulic cylinder. The tubular fixing frame 2 is made of steel pipe covered with rubber constitute. A retaining ring 3 is provided at the end of the tubular fixing frame 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com