Ultra-large linear energy input welding high-strength steel and production method thereof

A production method and technology for high-strength steel, which are used in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of difficulty in meeting the requirements of high-strength steel ultra-large line energy welding performance, and promote the secondary refinement of intragranular structure. , the effect of avoiding harmful inclusion content and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

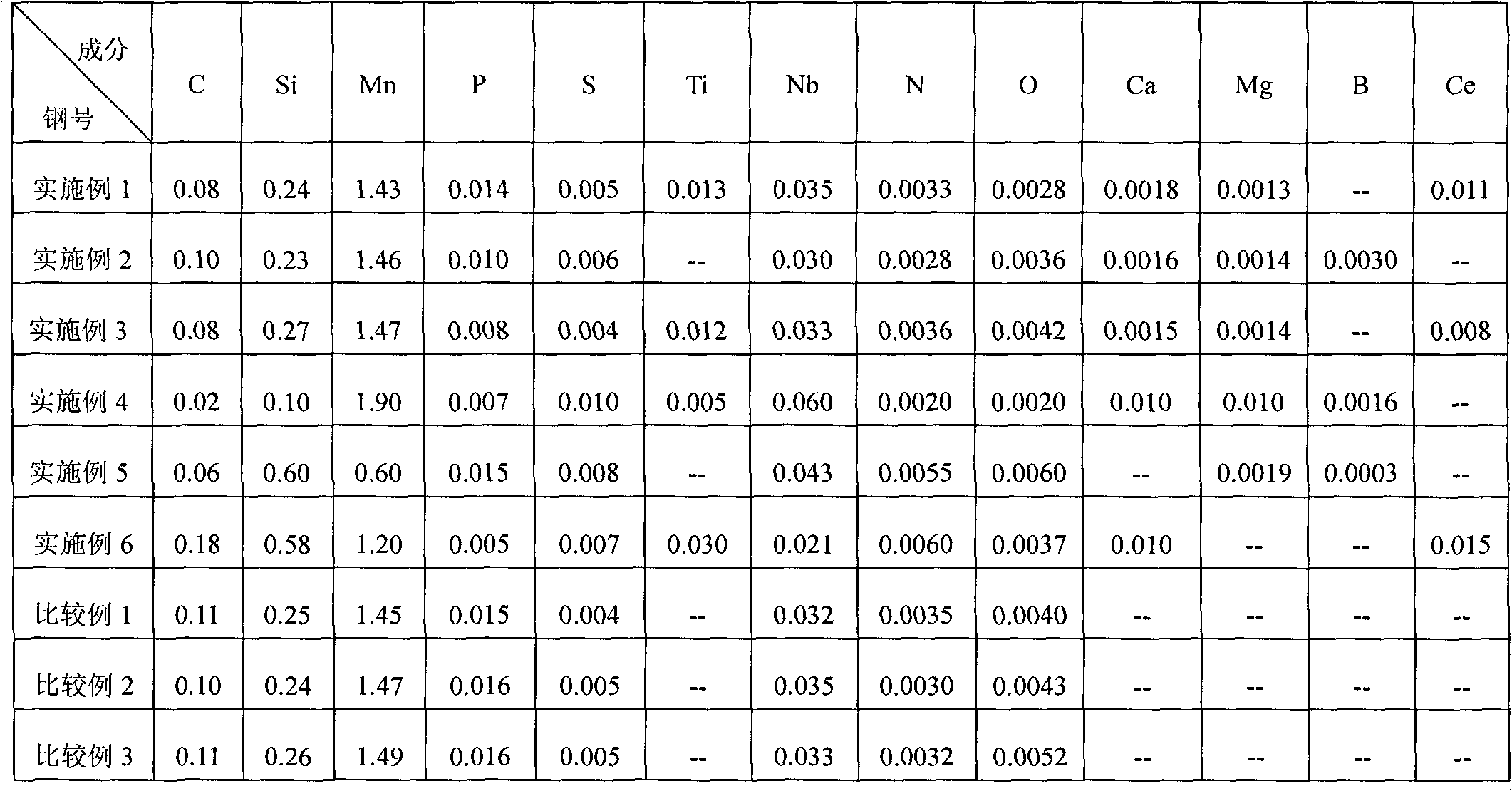

[0023] The steel with the specified composition in Table 1 is smelted in a converter, and cast slabs are made through desulfurization of molten iron, blowing at the top and bottom of the converter, vacuum deep treatment and fine-tuning of composition. Si-Mn is used as a deoxidizer to control the oxygen content of the tapped steel to ≤600ppm. The finished product Steel oxygen content ≤ 100ppm. The billet is heated to 1200-1310°C to fully austenitize it and then rolled out of the oven. Laminar cooling is carried out, the cooling rate of the steel plate is controlled at 5°C / s, the temperature of the steel plate is 660°C, and finally the steel plate is air-cooled to room temperature. The thickness of the rolled steel plate is 24mm.

Embodiment 2

[0025] In this example, the initial rolling temperature is 1210°C, the cumulative reduction rate of the last three passes is controlled at 40%, the final rolling temperature is 850°C, the cooling rate of the steel plate is controlled at 6°C / s, and the reddening temperature of the steel plate is 640°C. All the other are with embodiment 1. The thickness of the rolled steel plate is 20mm.

Embodiment 3

[0027] In this example, the initial rolling temperature is 1220°C, the cumulative reduction rate of the last three passes is controlled at 35%, the finishing temperature is 870°C, the cooling rate of the steel plate is controlled at 7°C / s, and the reddening temperature of the steel plate is 620°C , and finally air-cooled the steel plate to room temperature. Delivery with normalizing state again, normalizing temperature is 890~940 ℃, and holding time is: 30~40 minutes+plate thickness (mm)×1 minute / mm, all the other are the same as embodiment 1. The thickness of the rolled steel plate is 22mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com