Manufacturing method for rolling special shape at groove of edge part of coin or commemorative medallion

A manufacturing method and technology of commemorative badges, applied to coins, medals, badges, etc., can solve problems such as weak anti-counterfeiting functions, and achieve the effect of guaranteeing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

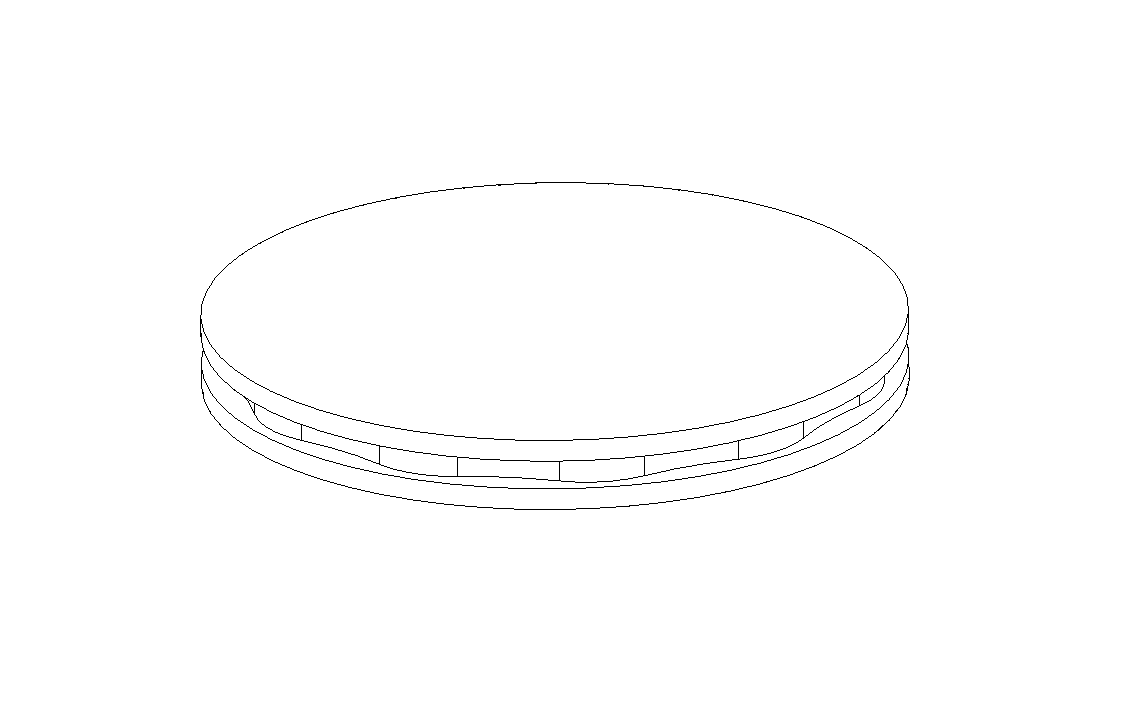

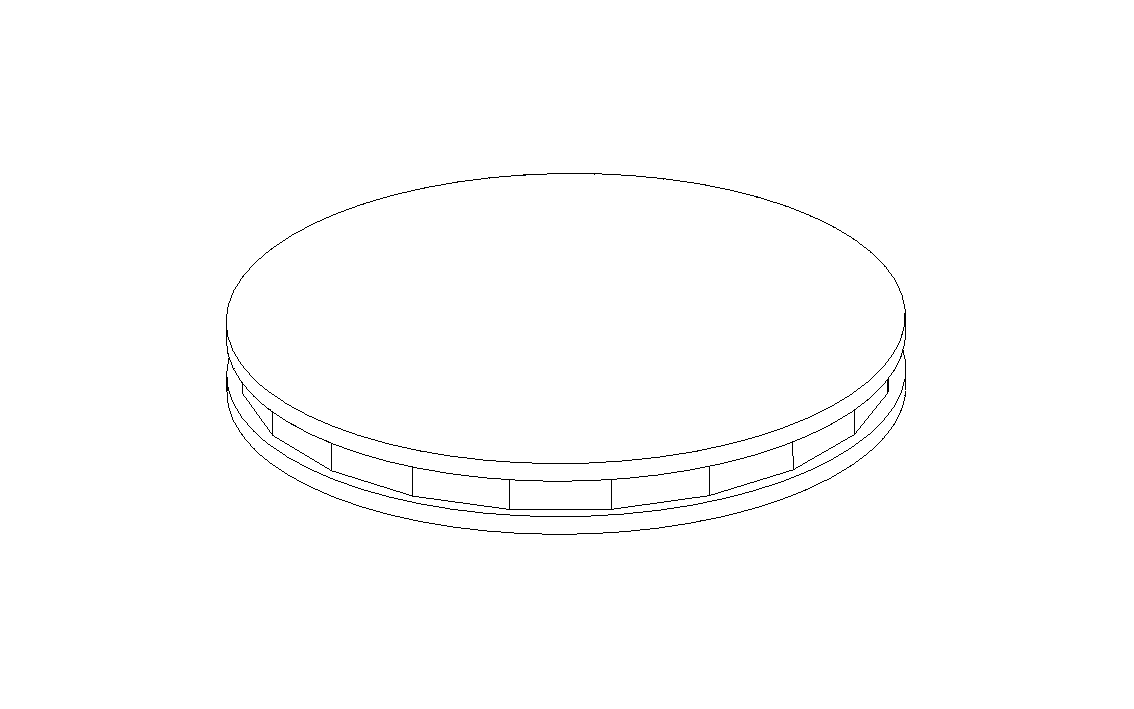

[0022] A method for manufacturing coins and medals with edge grooves of irregular shape, comprising the following steps: a, processing the electrodes into quincunx-shaped electrodes includes: a1, making electrode blanks, a2, fixing the electrode blanks on the engraved surface with a clamp machine, and then process it into plum-shaped special-shaped, a3. Connect the electrode handle and special-shaped electrode with fasteners to form a complete special-shaped electrode, such as image 3 As shown; b, processing the chip blank; c, fixing the complete special-shaped electrode and chip blank on the electric discharge forming machine with a jig, and then using the electric discharge forming machine to process the special-shaped quincunx-shaped chip, such as Figure 4 Shown; d, processing the upper and lower splints; e, combining the upper and lower splints and chips to form a bent plate; f, processing the disc, such as Figure 6 As shown; g, fix the disc and the curved plate on the ...

Embodiment 2

[0025] A method for manufacturing coins and medals with edge grooves of different shapes, comprising the following steps: a, processing the electrodes into polygonal electrodes includes: a1, making electrode blanks, a2, fixing the electrode blanks on the engraving machine with a clamp , and then processed into a polygonal shape, a3. Connect the electrode handle and the shaped electrode with a fastener to form a complete shaped electrode; b. Process the chip blank; c. Fix the complete shaped electrode and the chip blank on the EDM with a fixture On the machine, and then use the electric discharge forming machine to process chips with special shapes into polygons; d, process the upper and lower splints; e, combine the upper and lower splints and chips to form a bent plate; f, process the disc; g, fix the disc and the bent plate on On the edging machine, through the extrusion of metal, the side of the flat cake after shaving is formed with grooves and special shapes; h, through em...

Embodiment 3

[0027] Step is with embodiment 1. The shape of the irregular shape in this embodiment is a triangle.

[0028] The coin edge groove technology of the present invention is a coin edge anti-counterfeiting technology, which is to process a circle of grooves on the coin edge by extrusion molding. Usually, the center of the groove on the edge of the coin can also be rolled with words or patterns. During the product printing process, the groove can protect the middle text or pattern, so that the text or pattern in the groove will not be squeezed out by the mold sleeve due to the deformation and expansion of the edge during embossing. The coin side groove rolling special-shaped technology, that is, on the basis of maintaining the circular structure of the protruding groove columns on both sides, a special-shaped structure is processed in the groove, and the combination of the groove and the special-shaped structure is realized on the side of the coin, forming a new type Anti-counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com