Method for stamping interval half gear on edge of coin and souvenir badge

A commemorative badge and edge technology, which is applied to coins, medals, badges, etc., can solve the problems of the influence of semi-silk teeth, uneven force of large springs, and insufficient strength of mold sets, etc., to achieve the effect of guaranteed production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

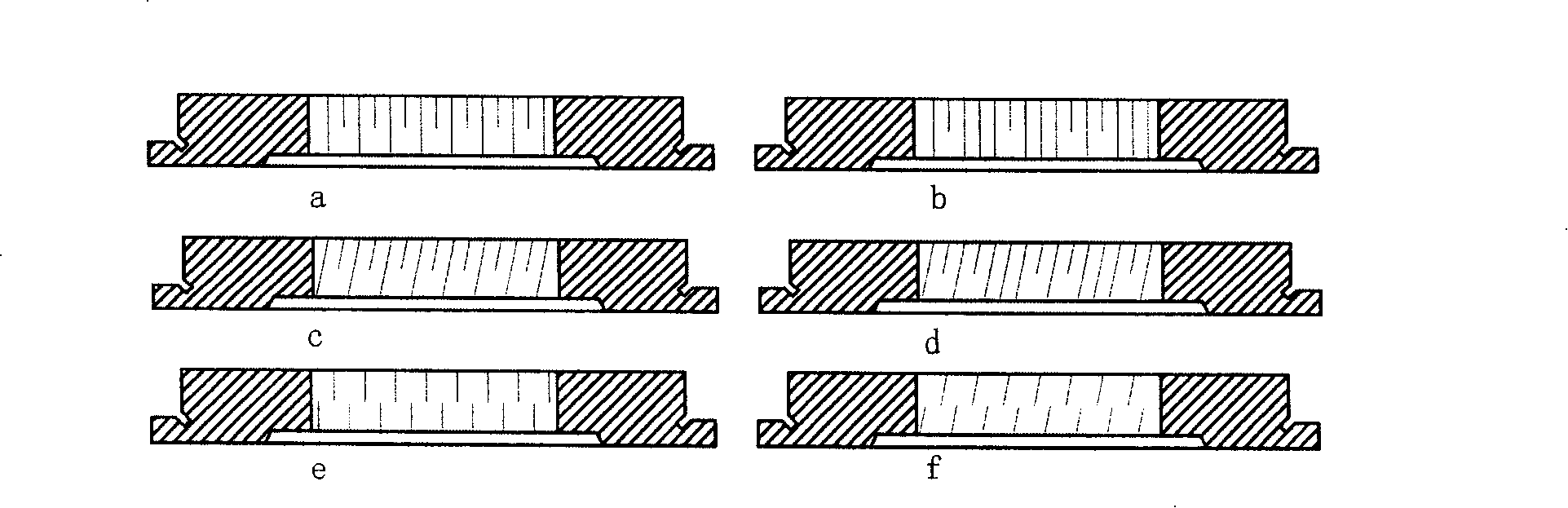

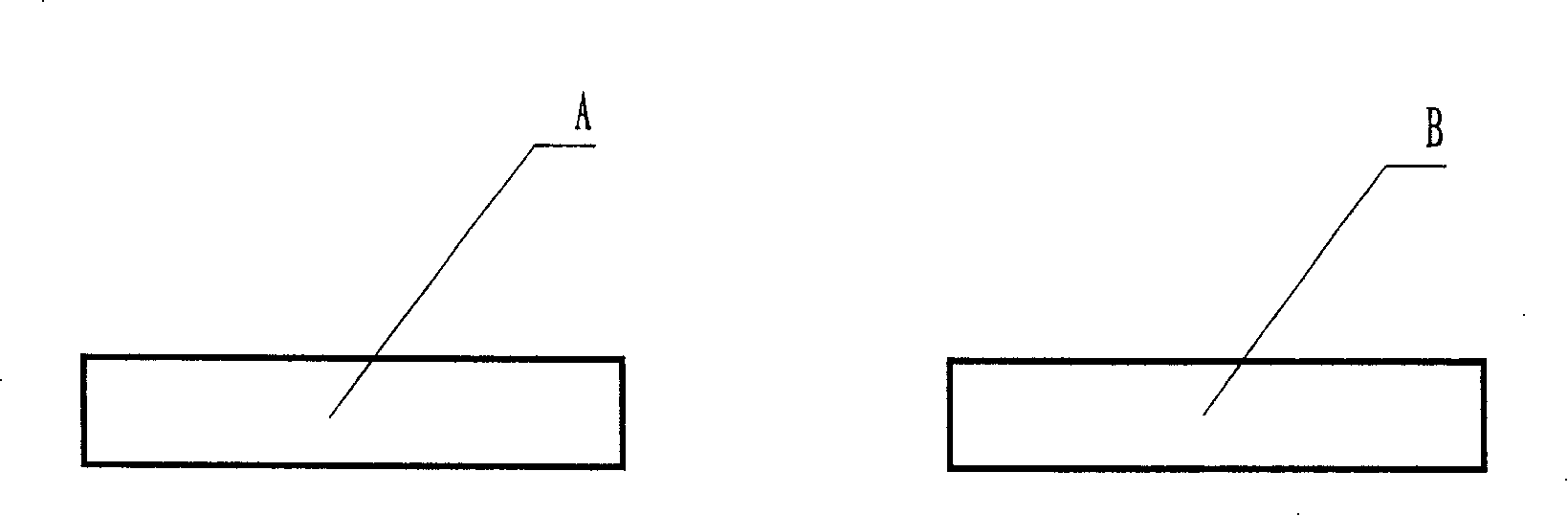

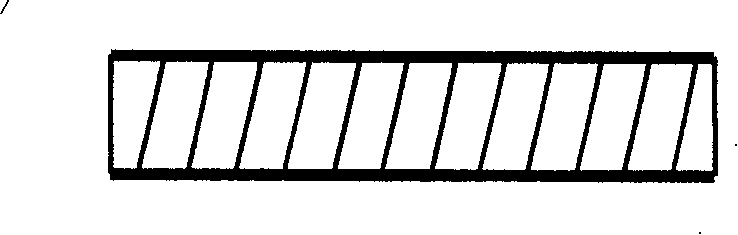

Embodiment 1

[0033] A method for printing half-spaced teeth on the edge of coins and medals, comprising the following steps: a, processing the electrode into half-toothed electrodes includes: a1, making the electrode blank into two parts A and B; a2, using a clamp to Part A is fixed on the wire cutting machine tool, and then processed into straight and sparse teeth; a3. Fix part B on the wire cutting machine tool with a fixture, and then process it into straight dense teeth with the wire cutting machine tool. The number of dense teeth is twice the number of sparse teeth; a4. The two parts of electrode A and B are connected and fastened together by fasteners, and the wire electrode composed of the upper and lower parts and the fasteners together form a complete spaced straight half-tooth electrode; b. Processing mold cover blanks; c . Fix the complete spaced straight half-tooth electrode and the die cover blank on the electric discharge forming machine with a fixture, and then use the electr...

Embodiment 2

[0035] The method of printing half-spaced teeth on the edge of coins and medals, wherein the electrodes are processed into spaced half-tooth electrodes, including: a11, making electrode blanks; a12, fixing the electrode blanks on the engraving machine, and then engraving them into left-handed spaced half-helical teeth Electrode; a13. Fasten the fasteners and spaced half-helical electrodes together to form a complete spaced half-helical electrode; process the mold cover blank, and fix the complete spaced half-helical electrode and the mold cover blank on the EDM on the forming machine, and then use the electric discharge forming machine to process the semi-oblique wire tooth mold sleeve. The EDM method is the C-axis rotary processing method; The printed product exits from the die set, and the imprinting device of the embossing fixture rotates relative to the helical tooth die set. The product that exits from the die set is a product with left-handed oblique wire teeth on the si...

Embodiment 3

[0037] The electrode in Example 1 is processed on a wire cutting machine tool with right-handed helical coarse teeth and helical dense teeth. Other steps are the same as in Example 1. Finally, the product with right-handed intermittent helical half teeth exits from the die set. The inclination of the wire teeth in this embodiment is 15 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com