Method for assembling pump-body of compressor with revolving twin cylinder

A technology of rotary compressor and assembly method, which is applied in the direction of rotary piston pump, rotary piston machine, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., which can solve the complex process and increase the cumulative error and other problems to achieve the effect of reducing the process, reducing the cumulative error and speeding up the production tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

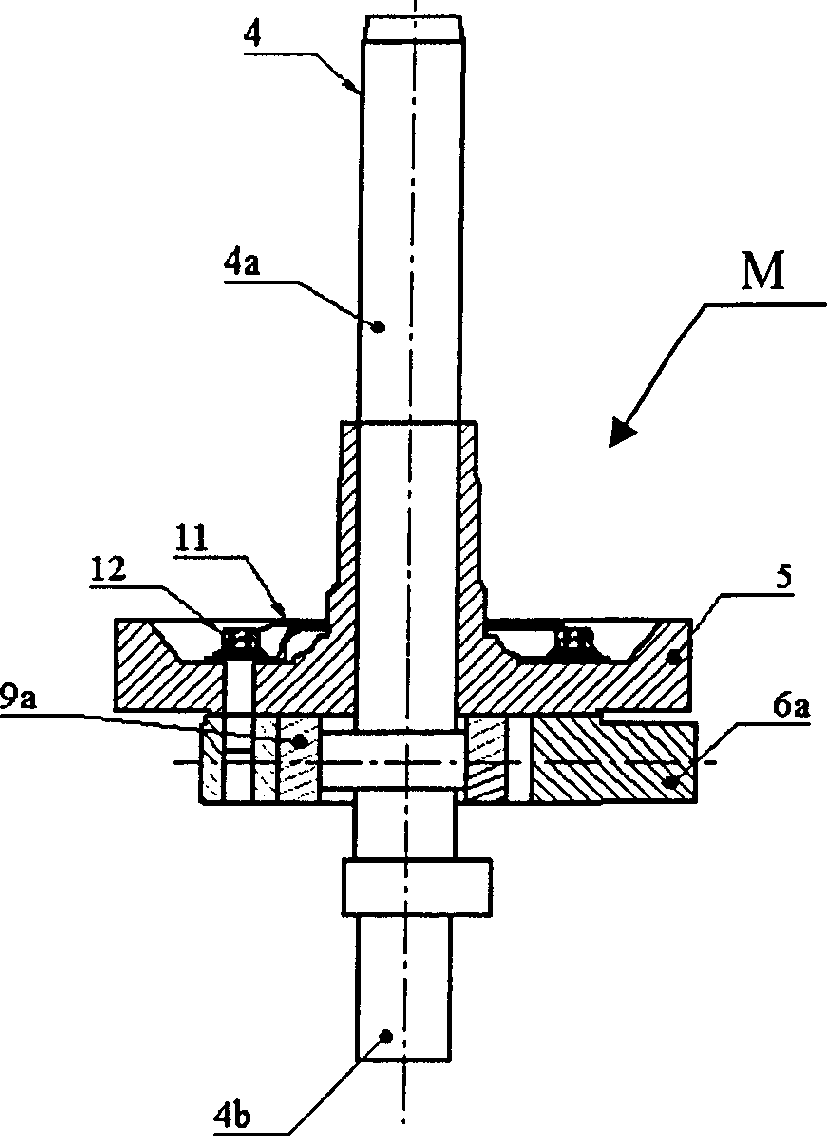

[0063] The pump body assembly method of the double-cylinder rotary compressor of the present invention includes the following steps:

[0064] See figure 1 As shown, this is a cross-sectional view of the piston and crankshaft assembly in a rotary compressor.

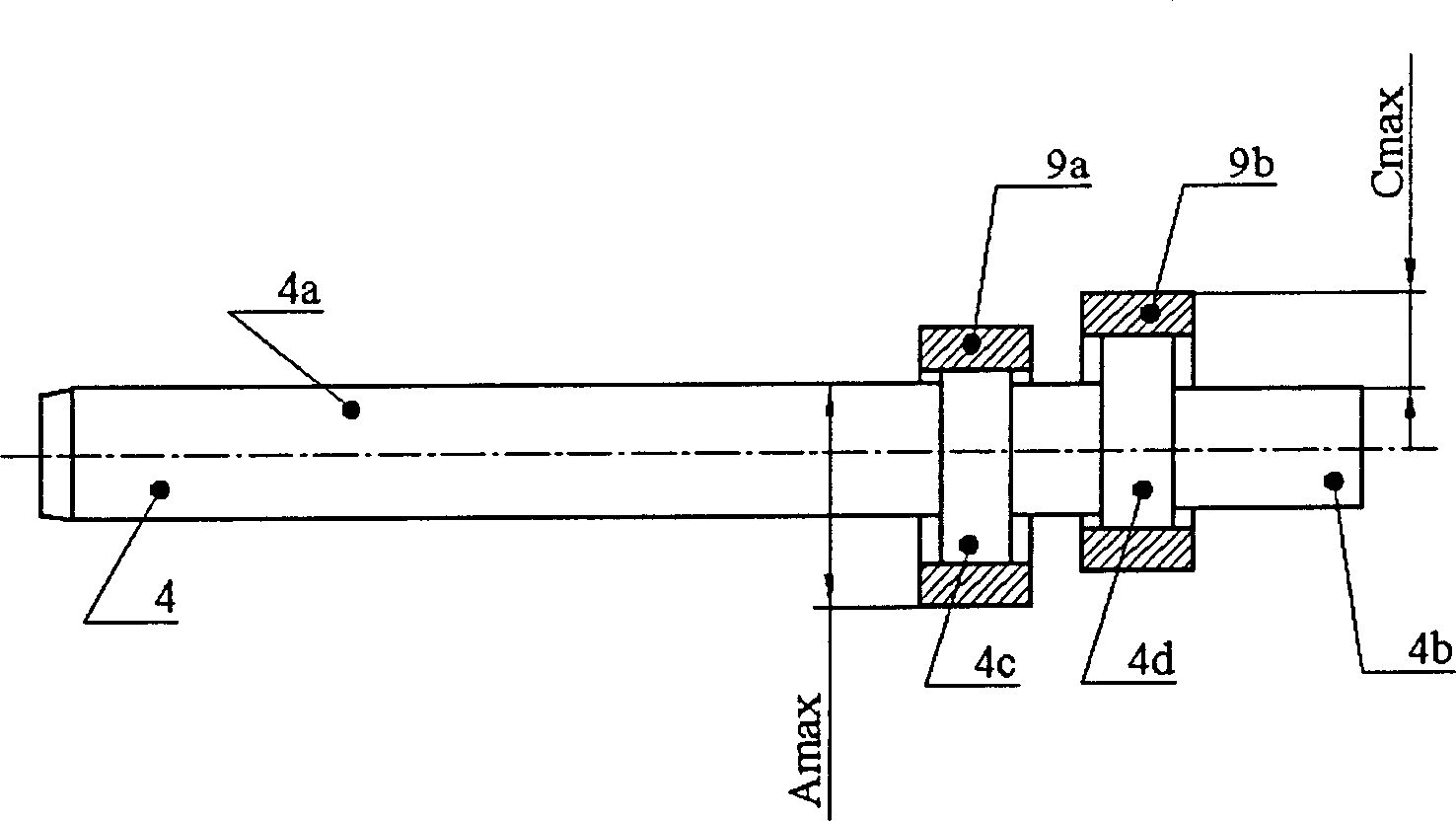

[0065] Step 1: Determine the upper and lower eccentric dimensions of the crankshaft 4; install the upper piston 9a and the lower piston 9b on the upper eccentric part 4c and lower eccentric part 4d of the crankshaft 4 respectively; measure the outer diameter of the upper piston 9a with an electric measuring instrument The maximum distance Amax from the outer diameter of the long axis 4a of the crankshaft 4 on the opposite side, that is, the upper eccentricity; measure the maximum distance from the outer diameter of the lower piston 9b to the outer diameter of the same side of the short axis 4b of the crankshaft 4 with an electric measuring instrument, that is, the lower eccentricity Cmax.

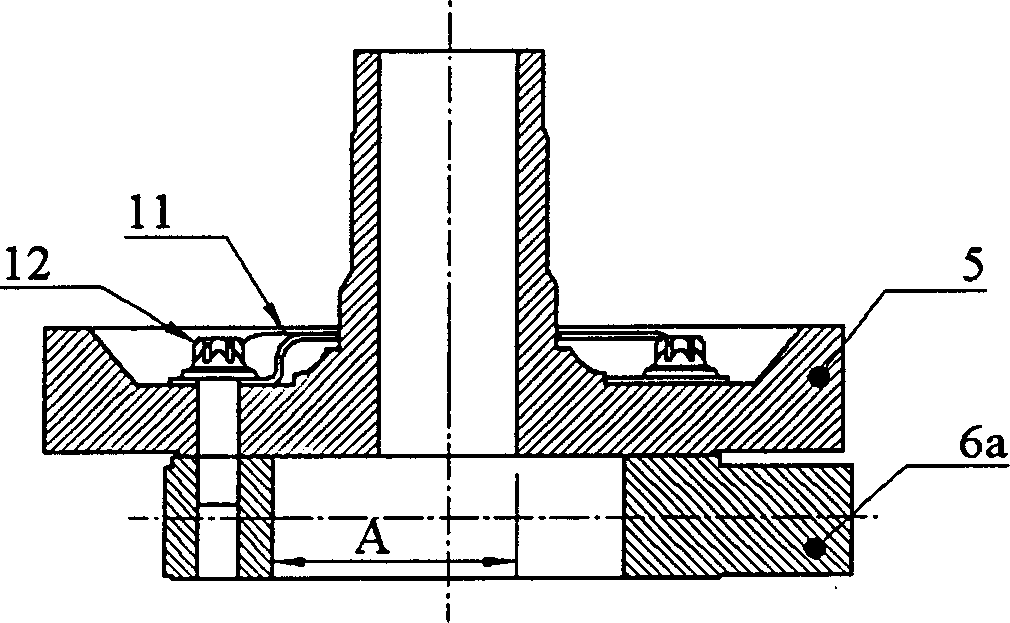

[0066] See figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com