High temperature-resistant and hydrogen sulfide corrosion-resistant steel plate for pressure vessels and manufacturing method thereof

A technology for resisting hydrogen sulfide and pressure vessels, applied in the field of low-alloy steel manufacturing, can solve problems such as inapplicability, and achieve the effects of reducing welding construction strength, improving the ability to resist elemental sulfur corrosion, and good high-temperature creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

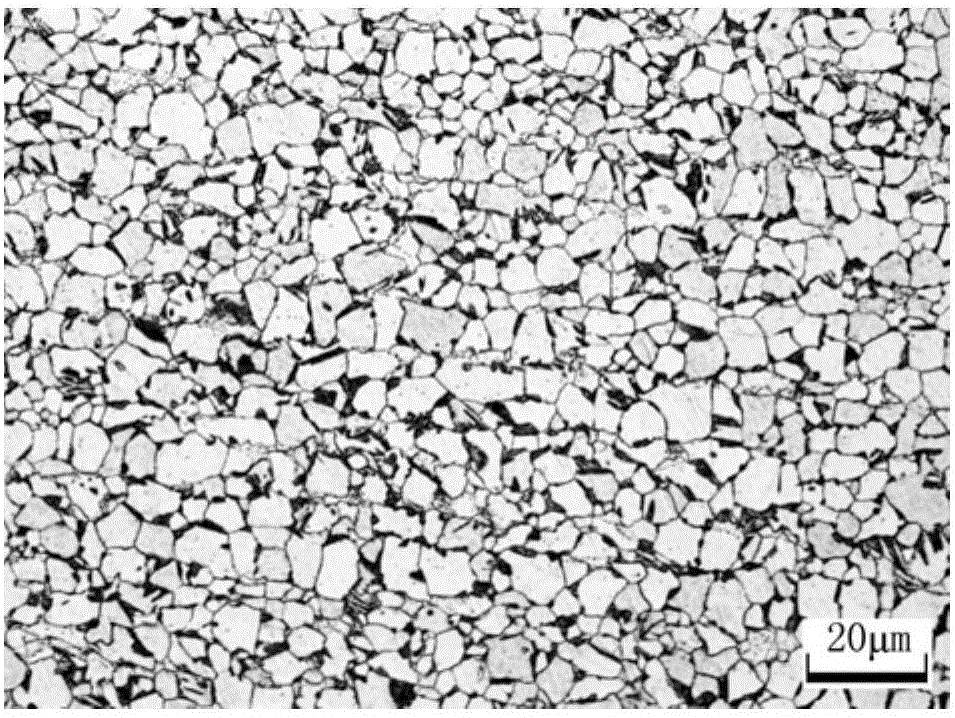

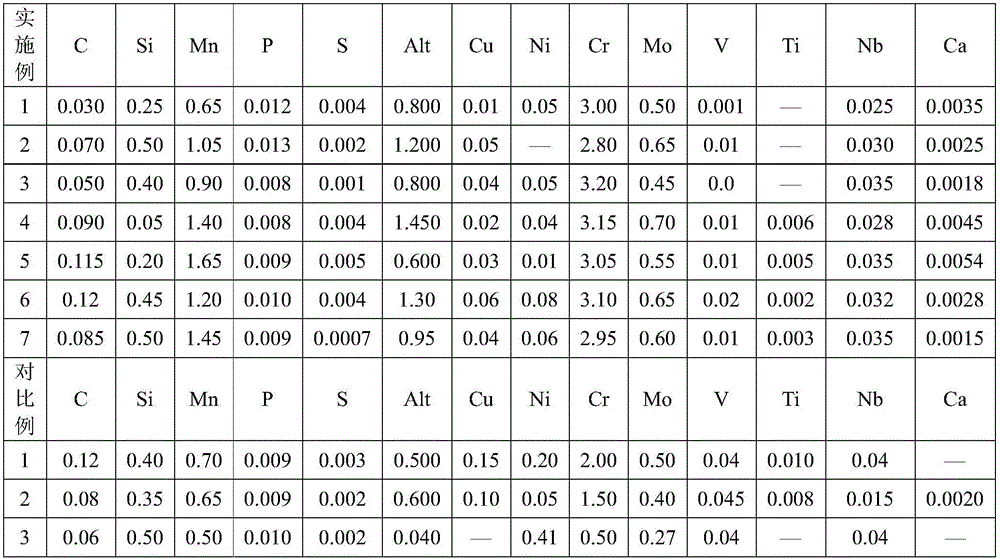

[0038] A steel plate for pressure vessels with high temperature resistance and hydrogen sulfide corrosion resistance, the main chemical composition of which is C0.03-0.115%, Si 0.05-0.50%, Mn 0.50-1.65, P 0.008-0.013%, S 0.001-0.005% by weight %, Alt (total aluminum content) 0.60-1.45%, Cr 2.8-3.20%, Mo 0.45-0.70%, Nb 0.020-0.035%, unavoidable inclusion Cu 0.01-0.06%, Ni 0-0.08%, V 0- 0.02%, Ti 0-0.006%, Ca 0.0015-0.0054%, and the rest is Fe. The details are shown in Table 1.

[0039] Table 1 each embodiment of the present invention and comparative example chemical composition value (wt, %)

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com