LPG boat storage tank steel plate and production method thereof

A production method and steel plate technology, applied in the field of metallurgy, can solve the problems of unguaranteed welding performance, high welding crack sensitivity coefficient, and unguaranteed low-temperature toughness of steel plates, etc., and achieve low welding crack sensitivity, excellent comprehensive mechanical properties, Good cold and hot processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

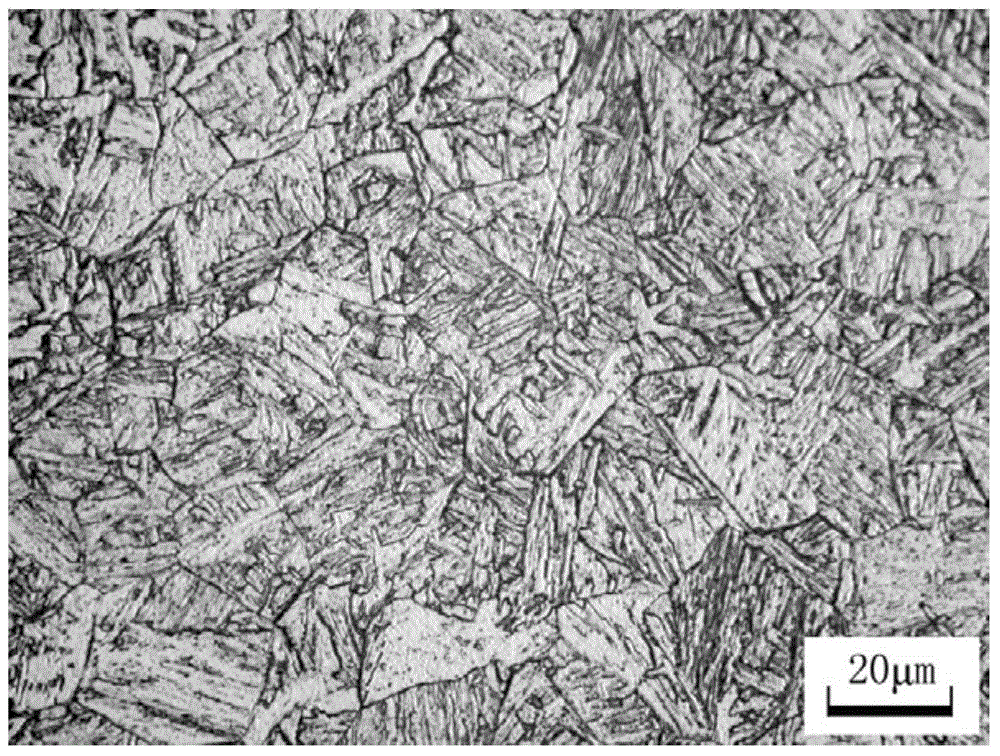

Image

Examples

Embodiment 1~7

[0041] Table 1 has listed the chemical composition and weight percentage of steel plates for LPG ship tanks in Examples 1 to 7 of the present invention, and the balance is Fe and unavoidable impurities. In addition, Table 1 has also listed the steel plates of each embodiment. Reheat crack susceptibility index G and P SR , steel plate hardenability coefficient D i , carbon equivalent CEV and welding crack sensitivity coefficient Pcm.

[0042] Table 1

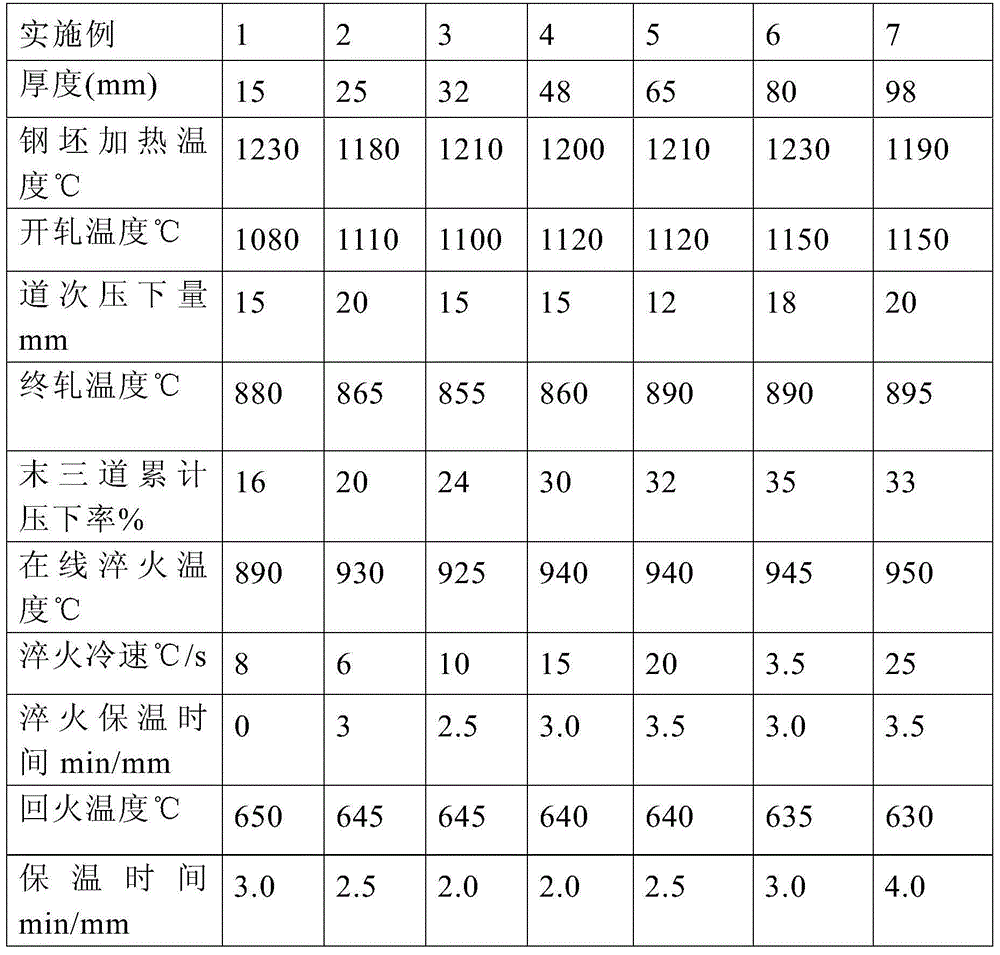

[0043] Example

1

2

3

4

5

6

7

Thickness (mm)

15

25

32

48

65

80

98

C

0.05

0.06

0.07

0.08

0.12

0.09

0.11

Si

0.25

0.3

0.1

0.15

0.1

0.1

0.2

mn

0.9

1

1

0.85

0.9

1.2

1.3

P

0.01

0.011

0.008

0.008

0.009

0.01

0.007

S

0.005

0.004

0.004

0.004

0.005

0.006

0.005

als

0.035

0.04

0.06...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com