A Preparation Method of Cu-Cr-Zr Alloy Ribbon Based on Subrapid Solidification

A sub-rapid solidification, cu-cr-zr technology, applied in the field of metallurgy, can solve the problems of difficult to control the type, size and shape of strengthening phase, limited solid solution or strengthening effect, low solubility of Cr and Zr, etc. The effect of reducing cold rolling reduction and suppressing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

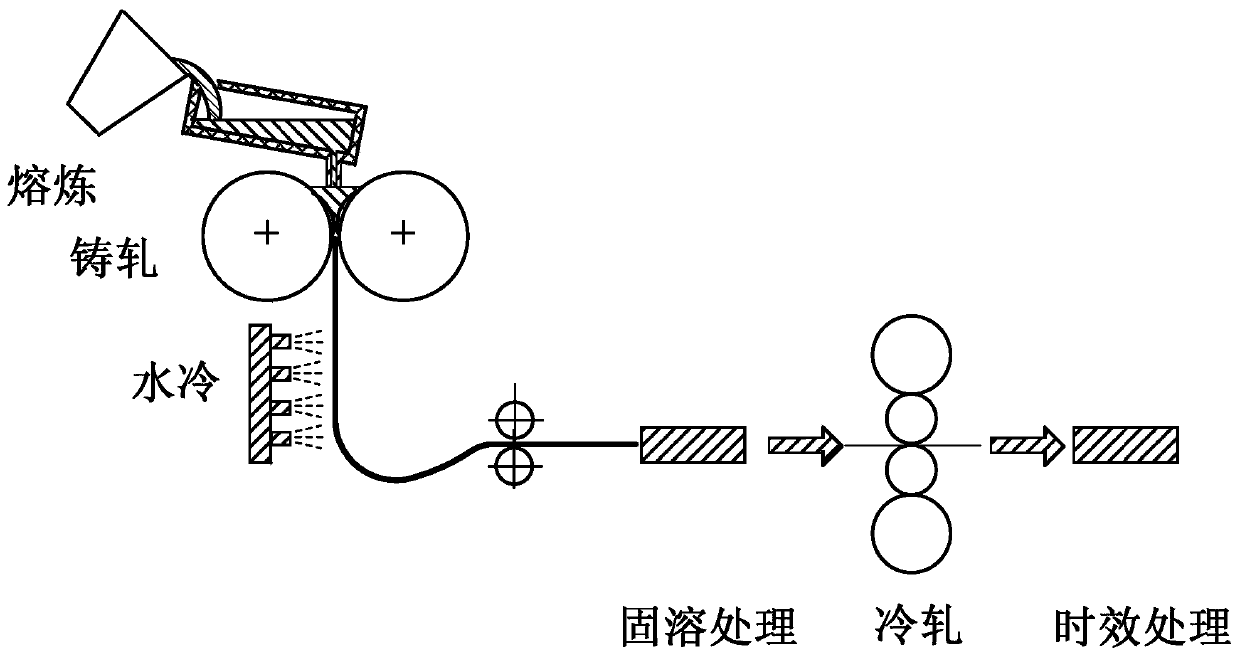

[0029] Process such as figure 1 As shown, the Cu-Cr-Zr alloy melt is smelted according to the design composition, and its composition contains Cr0.5% by mass percentage, Zr0.15%, impurities≤0.05%, and the rest is Cu;

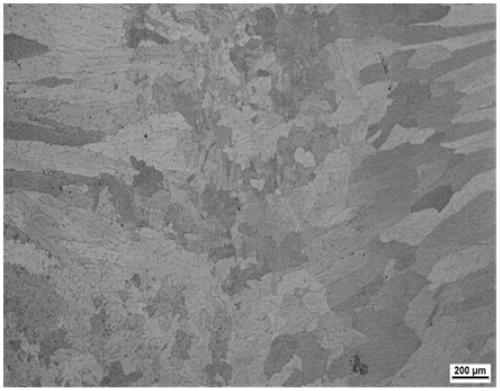

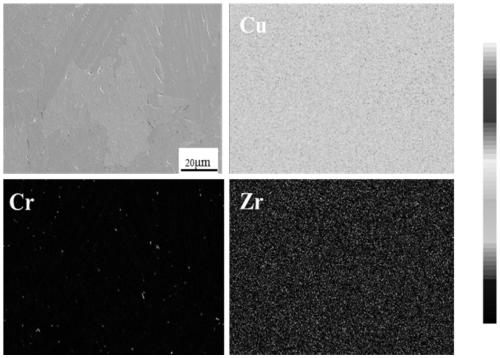

[0030] The molten Cu-Cr-Zr alloy melt enters the tundish through the gate, the superheat is controlled at 55±5°C, the tundish preheating temperature is 1000°C, and then poured into the twin-roll strip casting machine through the tundish for continuous casting. Obtain a cast strip with a thickness of 3.0mm. Spray water to cool the cast strip immediately after it leaves the casting roll. Control the cooling rate of the cast strip to 70±5°C / s, and take it up when it cools to 350°C; control the liquid level to 60mm during the continuous casting process. The roll speed is 40m / min; the metallographic structure of the cast strip is as follows figure 2 As shown, composition segregation detection (electron probe) as image 3 As shown in the figure, it can be seen that...

Embodiment 2

[0035] Method is with embodiment 1, and difference is:

[0036] (1) Cu-Cr-Zr alloy melt, its composition contains Cr 0.8%, Zr 0.1% by mass percentage;

[0037] (2) Control the degree of superheat to 60±5°C, the preheating temperature of the tundish to 1100°C, the thickness of the cast strip to be 1.0 mm, the cooling rate of the cast strip to be 65±5°C / s after it comes out of the casting roll, and coil it when it cools to 300°C; During the casting process, the liquid level is controlled to 50mm, and the roll speed is 35m / min;

[0038] (3) The total reduction rate of cold rolling is 85%; the thickness of cold rolled thin strip is 0.15mm;

[0039] (4) The aging treatment temperature is 400°C, time is 4h, the tensile strength of the Cu-Cr-Zr alloy strip is 610MPa, the electrical conductivity is 84.5%IACS, and the hardness is 240HV.

Embodiment 3

[0041]Method is with embodiment 1, and difference is:

[0042] (1) Cu-Cr-Zr alloy melt, its composition contains Cr 1.0% and Zr 0.2% by mass percentage;

[0043] (2) Control superheat to 85±5°C, tundish preheating temperature to 1150°C, casting strip thickness to 2.0mm, cooling speed of casting strip to 75±5°C / s after leaving the casting roll, coiling when cooling to 320°C; During the casting process, the liquid level is controlled to 70mm, and the roll speed is 45m / min;

[0044] (3) DSC analysis was carried out on the cast strip sample after coiling, and there was an endothermic peak at 970°C, so it was solid solution treated at 970°C for 0.5h, water quenched to room temperature, and DSC analysis was performed again, and the results showed that there was no obvious endothermic process ;

[0045] (4) The total reduction rate of cold rolling is 90%; the thickness of cold rolled thin strip is 0.2mm;

[0046] (5) The aging treatment temperature is 450°C, the time is 2h, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com