Preparation method of ultrathin Ta-W alloy foil

A kind of alloy foil, ultra-thin technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that high-power high-performance microwave tubes cannot be applied, the surface quality of alloys deteriorates, and the processing performance at room temperature decreases. Achieve high room temperature strength and high temperature strength, good surface quality, and high-precision surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

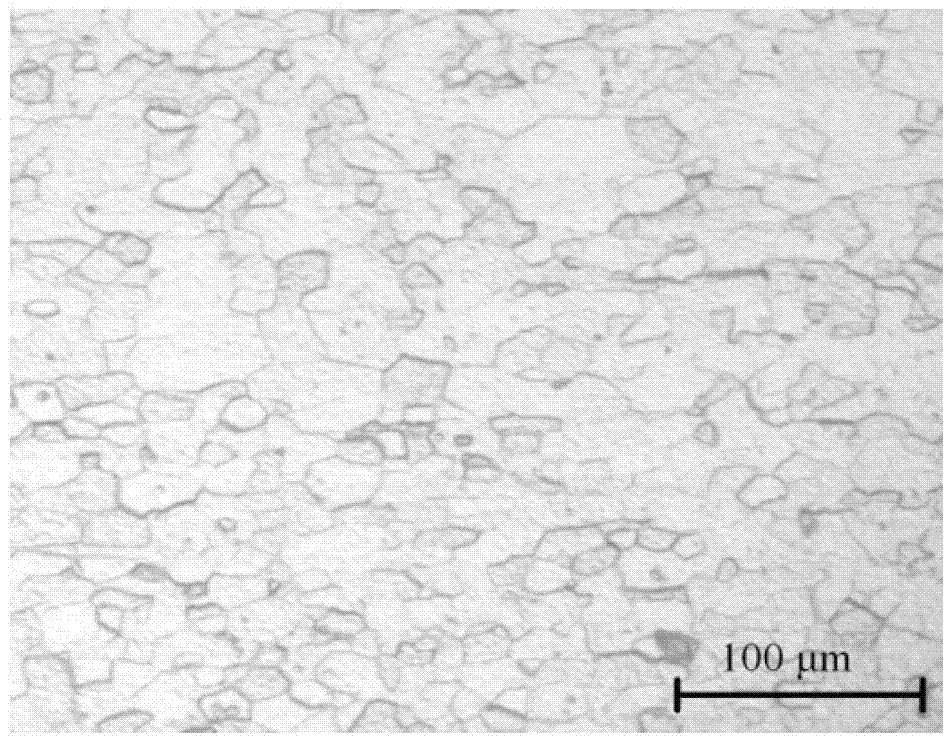

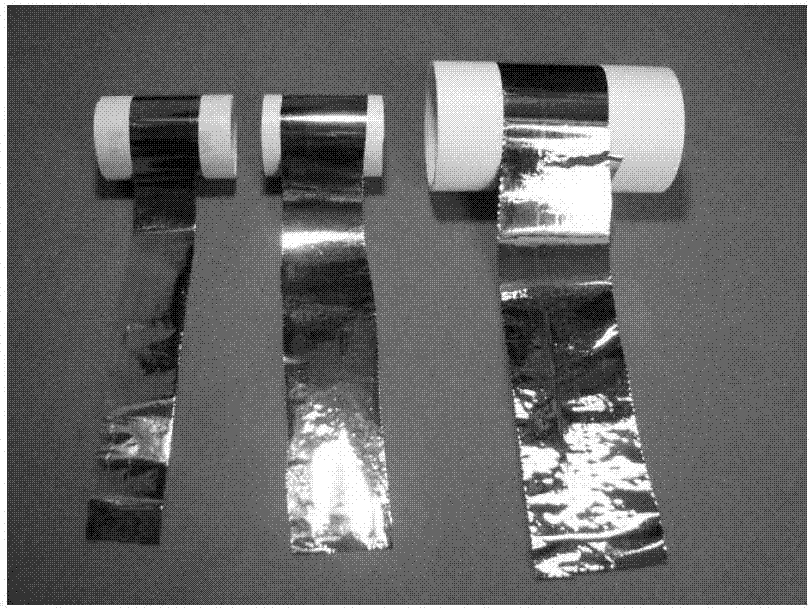

[0037] An ultra-thin Ta-W alloy foil prepared in this embodiment has an alloy composition of: W: 5.0 wt%, and the balance is Ta.

[0038] According to the alloy composition, Ta powder with a purity of ≥99.99% and an average particle size of 5-10 μm and W powder with a purity of ≥99.99% and an average particle size of -4 Pa, the temperature is 600°C and the alloy powder is isostatically pressed, the forming pressure is 180Mpa, the holding time is 10min, and then the absolute vacuum degree is -3 The primary sintering is carried out in the environment of Pa, the sintering temperature is 2300°C, and the sintering time is 2h; after the primary sintered billet is subjected to cold rolling with a deformation of 50%, the absolute vacuum degree is -3 The secondary sintering is carried out in the environment of Pa, the sintering temperature is 2300 ℃, and the sintering time is 1h; then the secondary sintered billet is subjected to cold rolling with a deformation of 50%, and the absolute va...

Embodiment 2

[0046] A Ta-W alloy foil material for electric vacuum prepared in this embodiment, the alloy composition is: W: 6.0wt%, and the balance is Ta.

[0047] Using Ta powder with a purity ≥ 99.99% and an average particle size of 5-10 μm and W powder with a purity ≥ 99.99% and an average particle size -4 Pa, the temperature is 620°C and the alloy powder is isostatically pressed, the forming pressure is 190Mpa, the holding time is 12min, and then the absolute vacuum degree is -3 The primary sintering is carried out in an environment of Pa, the sintering temperature is 2400°C, and the sintering time is 3h; after the primary sintered billet is subjected to cold rolling with a deformation of 55%, the absolute vacuum degree is -3 The secondary sintering is carried out in the environment of Pa, the sintering temperature is 2400 ℃, and the sintering time is 0.75h; then the secondary sintered billet is subjected to cold rolling with a deformation of 55%, and the absolute vacuum degree is -3 Thr...

Embodiment 3

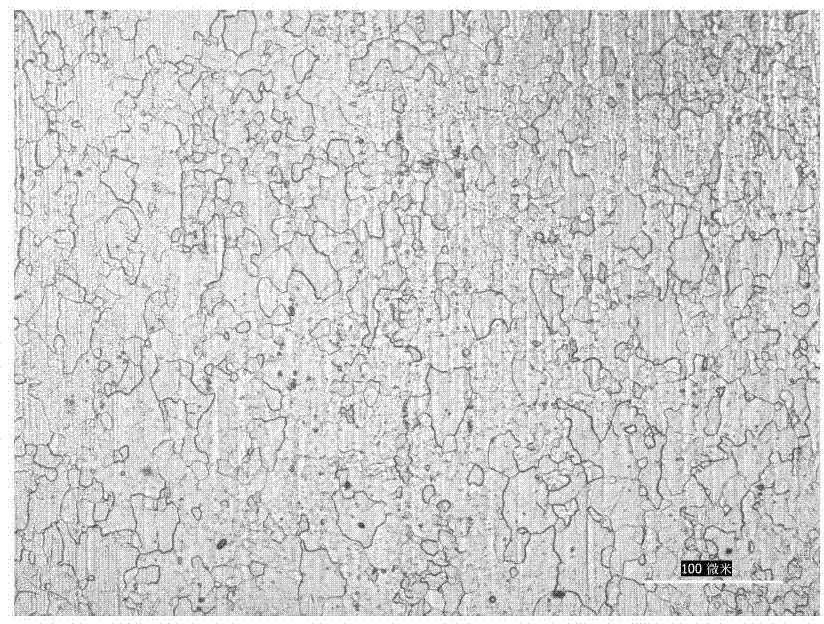

[0055] A Ta-W alloy foil material for electric vacuum prepared in this example, the alloy composition is: W: 7.5wt%, and the balance is Ta.

[0056] Using Ta powder with a purity ≥ 99.99% and an average particle size of 5-10 μm and W powder with a purity ≥ 99.99% and an average particle size -4 Pa, the temperature is 650°C, and then the alloy powder is isostatically pressed, the forming pressure is 200Mpa, the holding time is 15min, and then the absolute vacuum degree is -3 The primary sintering is carried out in the environment of Pa, the sintering temperature is 2500°C, and the sintering time is 4h; after the primary sintered billet is subjected to cold rolling with a deformation of 60%, the absolute vacuum degree is -3 The secondary sintering is carried out in the environment of Pa, the sintering temperature is 2500 ℃, and the sintering time is 1h; then the secondary sintered billet is subjected to cold rolling with a deformation of 60%, and the absolute vacuum degree is -3 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com