A kind of manufacturing method of silicon-containing stainless steel seamless pipe

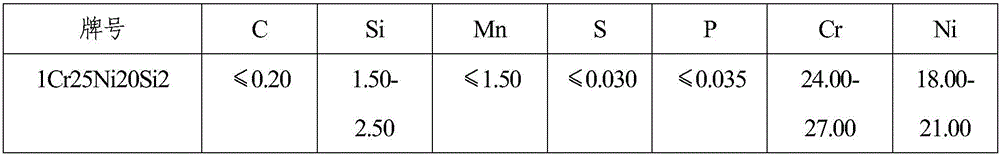

A manufacturing method and stainless steel technology are applied in the field of control of the cold-worked surface quality of silicon-containing stainless steel 16Cr25Ni20Si2 to achieve the effects of increasing heat treatment temperature, saving operating costs and shortening holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 (Steel pipe representative specification φ38×3mm)

[0047] 1. Tube billet heating—piercing → cold rolling → (short-time high temperature) heat treatment → (both positive and negative) straightening → pickling.

[0048] 2. Heat treatment in a roller hearth heat treatment furnace with a temperature of 1090°C, a heat preservation coefficient of 1.0min / mm, and a heat preservation time of 1.0min / mm×3mm=3.0min. Pickling, the surface has no pitting and residual scale, and the mechanical properties of the finished product are qualified. (See Table 4 below)

[0049] 3. Steel pipe heating, piercing and other processes are conventional steel pipe processes, the implementation process is smooth, the mechanical properties of the finished product are qualified, the surface quality is good, and there is no impact on environmental protection and safety.

Embodiment 2

[0050] Embodiment 2 (steel pipe represents finished product specification 38 * 3mm)

[0051] 1. Tube billet heating—piercing → cold rolling → (short-time high temperature) heat treatment → (both positive and negative) straightening → pickling.

[0052] 2. Heat treatment in a roller hearth heat treatment furnace, the temperature is 1100°C, the heat preservation coefficient is 1.2min / mm, and the heat preservation time is 1.2min / mm×3mm=3.6min. Pickling, the surface has no pitting and residual scale, and the mechanical properties of the finished product are qualified. (See Table 4 below)

[0053] 3. Steel pipe heating, piercing and other processes are conventional steel pipe processes, the implementation process is smooth, the mechanical properties of the finished product are qualified, the surface quality is good, and there is no impact on environmental protection and safety.

Embodiment 3

[0054] Embodiment 3 (steel pipe represents finished product specification 38 * 3mm)

[0055] 1. Tube billet heating—piercing → cold rolling → (short-time high temperature) heat treatment → (both positive and negative) straightening → pickling.

[0056] 2. Heat treatment in a roller hearth heat treatment furnace, the temperature is 1110°C, the heat preservation coefficient is 1.3min / mm, and the heat preservation time is 1.3min / mm×3mm=3.9min. Pickling, the surface has no pitting and residual scale, and the mechanical properties of the finished product are qualified. (See Table 4 below)

[0057] 3. Steel pipe heating, piercing and other processes are conventional steel pipe processes, the implementation process is smooth, the mechanical properties of the finished product are qualified, the surface quality is good, and there is no impact on environmental protection and safety.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com