Method for controlling pin positioning accuracy by seamless tube extrusion locking pin process

A technology for extruding fixed, seamless pipes, applied in metal extrusion control equipment, metal extrusion, manufacturing tools, etc., can solve the problems of poor control accuracy, long opening and closing time of control valves, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

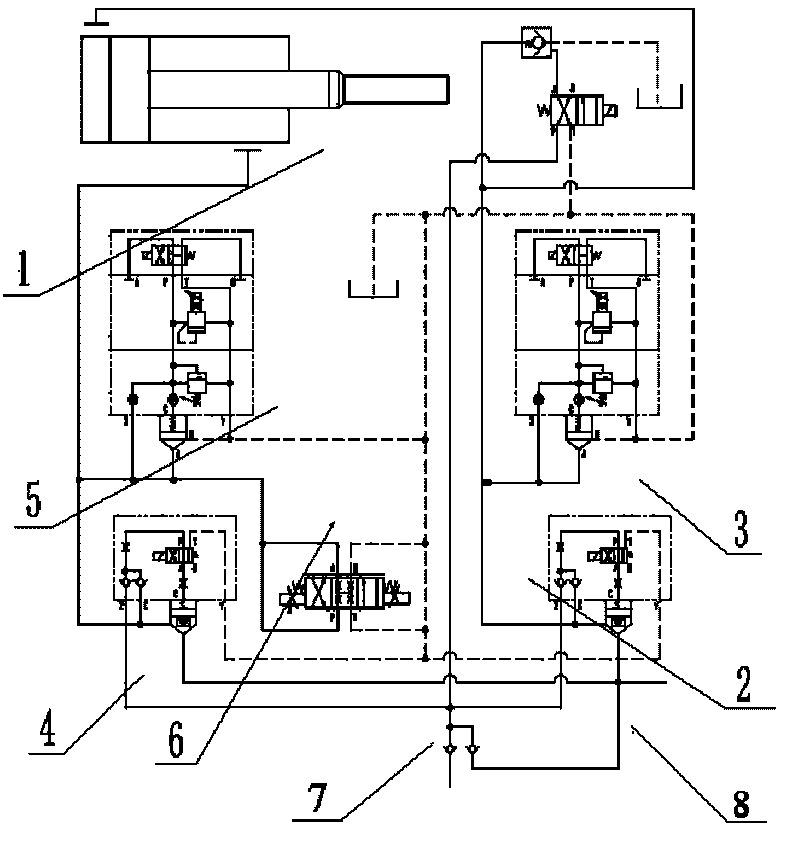

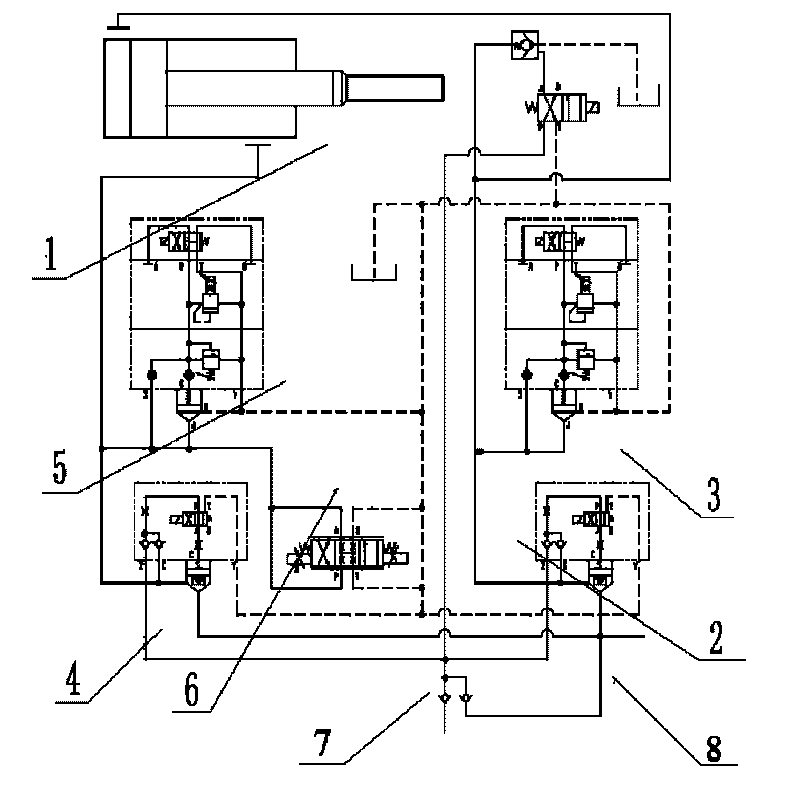

[0010] Such as figure 1 As shown, the precision control method of the seamless pipe extrusion fixed needle process at least includes: perforated cylinder 1, piston chamber oil inlet valve 2, piston chamber liquid discharge valve 3, piston rod chamber oil inlet valve 4 and piston rod chamber discharge valve The liquid valve 5 is connected with the piston chamber oil inlet valve 2 and the piston chamber liquid discharge valve 3 on the oil path of the piston chamber of the perforated oil cylinder 1, and the piston rod chamber oil inlet valve 4 and the piston rod chamber are arranged on the oil path of the piston rod chamber of the perforated oil cylinder 1. Cavity drain valve 5, the advance and retreat of perforated cylinder 1 are respectively controlled by perforated cylinder piston chamber oil inlet valve 2, piston chamber drain valve 3, piston rod chamber oil inlet valve 4 and piston rod chamber drain valve 5, when the main pump oil Oil comes from source 8, piston chamber oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com