Method for producing steel plate with extra deep drawing iron and zinc alloy plating layer

A steel plate production method and alloy coating technology, applied in metal material coating technology, coating, hot-dip coating technology, etc., can solve the problems of slow cooling speed, etc., and achieve the effect of improved pulverization resistance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

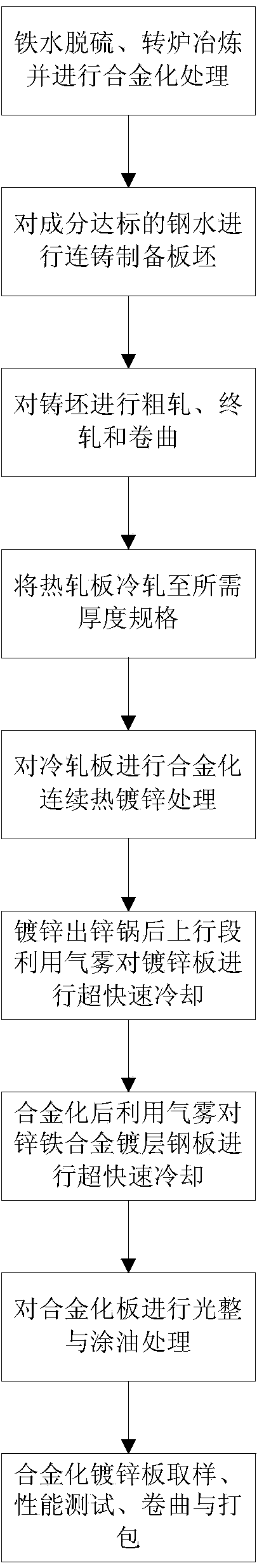

[0023] see figure 1 , the present invention has the steel plate production method of ultra-deep drawing iron-zinc alloy coating, comprises the steps:

[0024] 1) Desulfurization of molten iron, converter smelting and alloying treatment;

[0025] 2) Carry out continuous casting to the molten steel whose composition reaches the standard to prepare a slab;

[0026] 3) Rough rolling is carried out on the slab, the rough rolling temperature is controlled at 1060°C, the final rolling temperature is controlled at 890°C, and the curling temperature is controlled at 680°C;

[0027] 4) Cold rolling the hot-rolled plate to the required thickness specification;

[0028] 5) Carry out alloying continuous hot-dip galvanizing treatment on the cold-rolled sheet, in which the speed of the unit is controlled at 90m / min, the heating temperature is controlled at 830°C, the temperature of the fast cooling section is controlled at 500°C, and the gas is used in the upward section after galvanizing ...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, the difference is that:

[0036] 3) Rough rolling is carried out on the slab, the rough rolling temperature is controlled at 1068°C, the final rolling temperature is controlled at 897°C, and the curling temperature is controlled at 696°C;

[0037] 5) Carry out alloying and continuous hot-dip galvanizing treatment on the cold-rolled sheet, in which the speed of the unit is controlled at 93m / min, the heating temperature is controlled at 837°C, the temperature of the fast cooling section is controlled at 506°C, and the gas is used in the upward section after galvanizing out of the galvanizing pot. The mist is used to cool the galvanized sheet, and the cooling rate is controlled at 43°C / s. After alloying, the zinc-iron alloy coated steel sheet is cooled with the fog, and the cooling rate is controlled at 39°C / s;

[0038] 6) Carry out skinning and oiling treatment on the alloyed plate, wherein the skinning elongation is co...

Embodiment 3

[0042] This embodiment is basically the same as Embodiment 1, the difference is that:

[0043] 3) Rough rolling is carried out on the slab, the rough rolling temperature is controlled at 1084°C, the final rolling temperature is controlled at 904°C, and the curling temperature is controlled at 707°C;

[0044] 5) Carry out alloying continuous hot-dip galvanizing treatment on the cold-rolled sheet, in which the speed of the unit is controlled at 96m / min, the heating temperature is controlled at 841°C, the temperature of the fast cooling section is controlled at 509°C, and the upward section after galvanizing is out of the galvanizing pot uses gas The mist is used to cool the galvanized sheet, and the cooling rate is controlled at 52°C / s;

[0045] 6) Carry out skinning and oiling treatment on the alloyed plate, wherein the skinning elongation is controlled at 0.3%, and the amount of oiling on the upper and lower surfaces is 19g / m 2 .

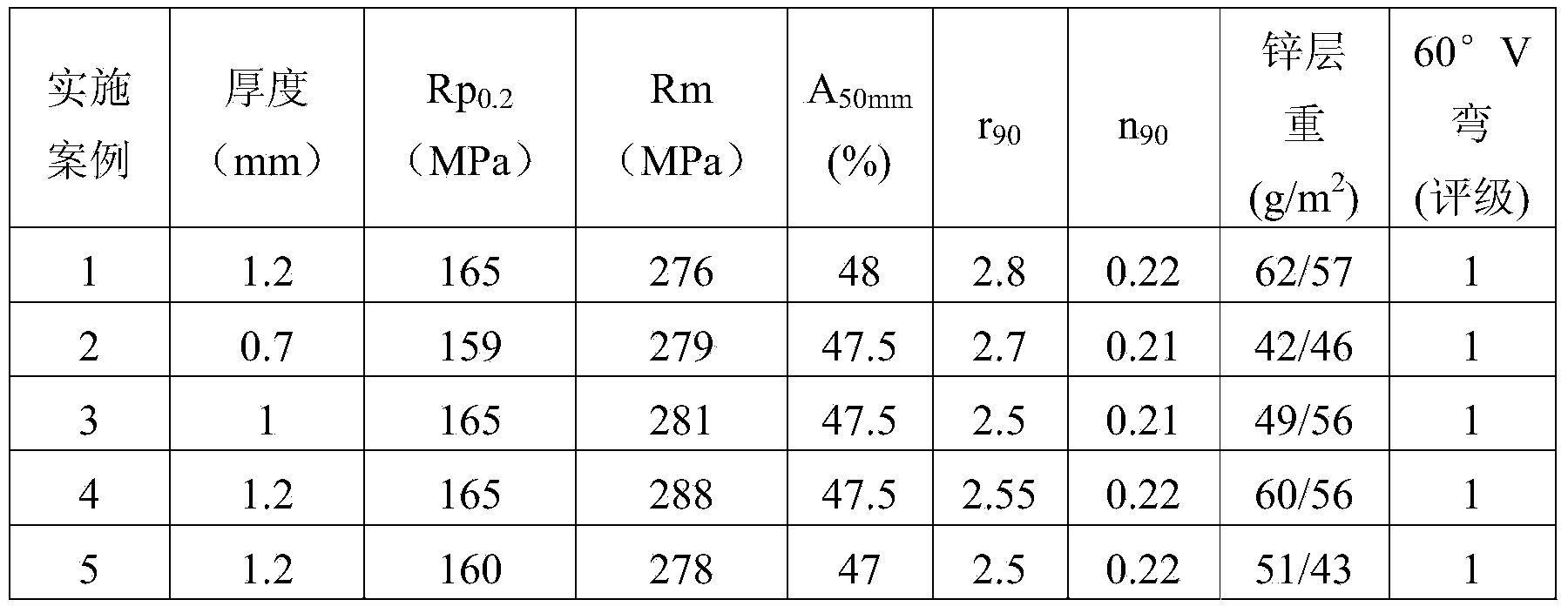

[0046] After adopting the technical solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com