450MPa-level zinc iron alloy clad layer double-phase steel plate for car outer plate and manufacturing method thereof

A technology of zinc-iron alloy and dual-phase steel, applied in metal material coating process, coating, hot-dip coating process, etc., to achieve the effect of excellent anti-powdering performance, no defect in color and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

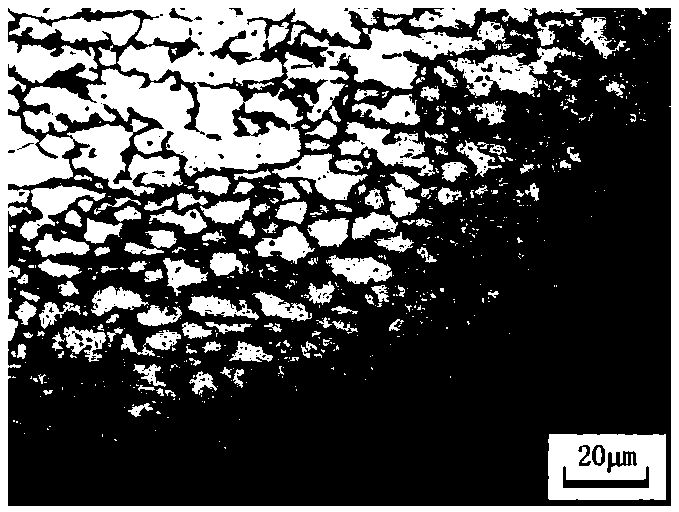

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

[0044] Facing the present invention be described in detail:

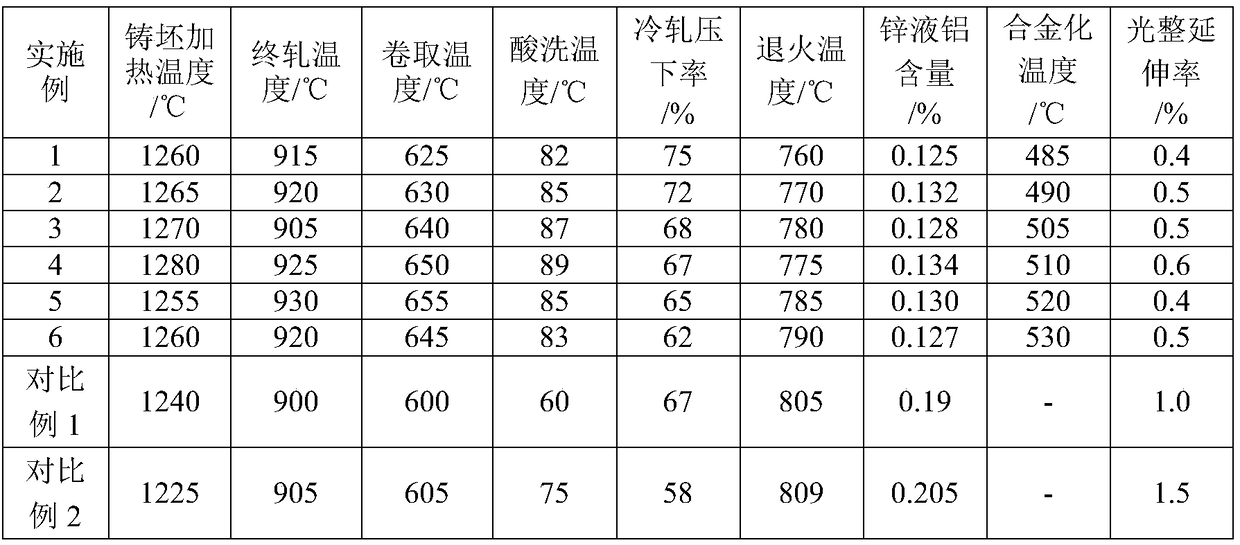

[0045] Table 1 is the value list of each embodiment of the present invention and comparative example;

[0046] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0047] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0048] Each embodiment of the present invention is produced according to the following steps:

[0049] 1) After smelting, refining and continuous casting according to the weight percentage of the following chemical components, the billet is heated, and the heating temperature is controlled at 1250-1280 °C;

[0050] 2) Rough rolling: control the rough rolling temperature at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com