Direct connection low-speed small-scale mixed-flow turbine applied in hydrodynamic energy-saving cooling tower

A technology of cooling towers and water turbines, applied in the direction of reaction engines, engine components, impact engines, etc., can solve the problems of high manufacturing and maintenance costs, high failure rate, small size, etc., to improve efficiency, reduce noise, reduce manufacturing and maintenance cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

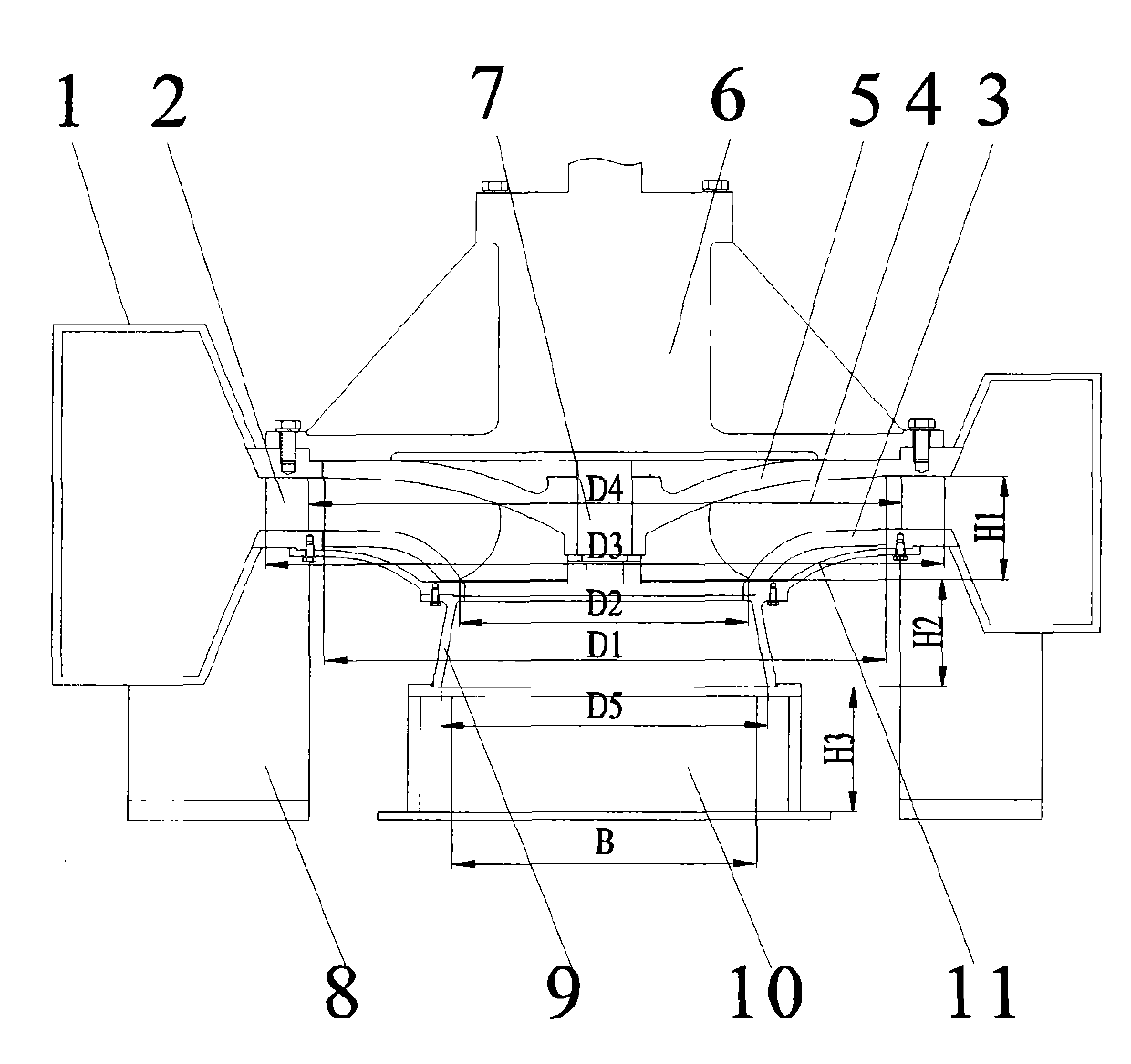

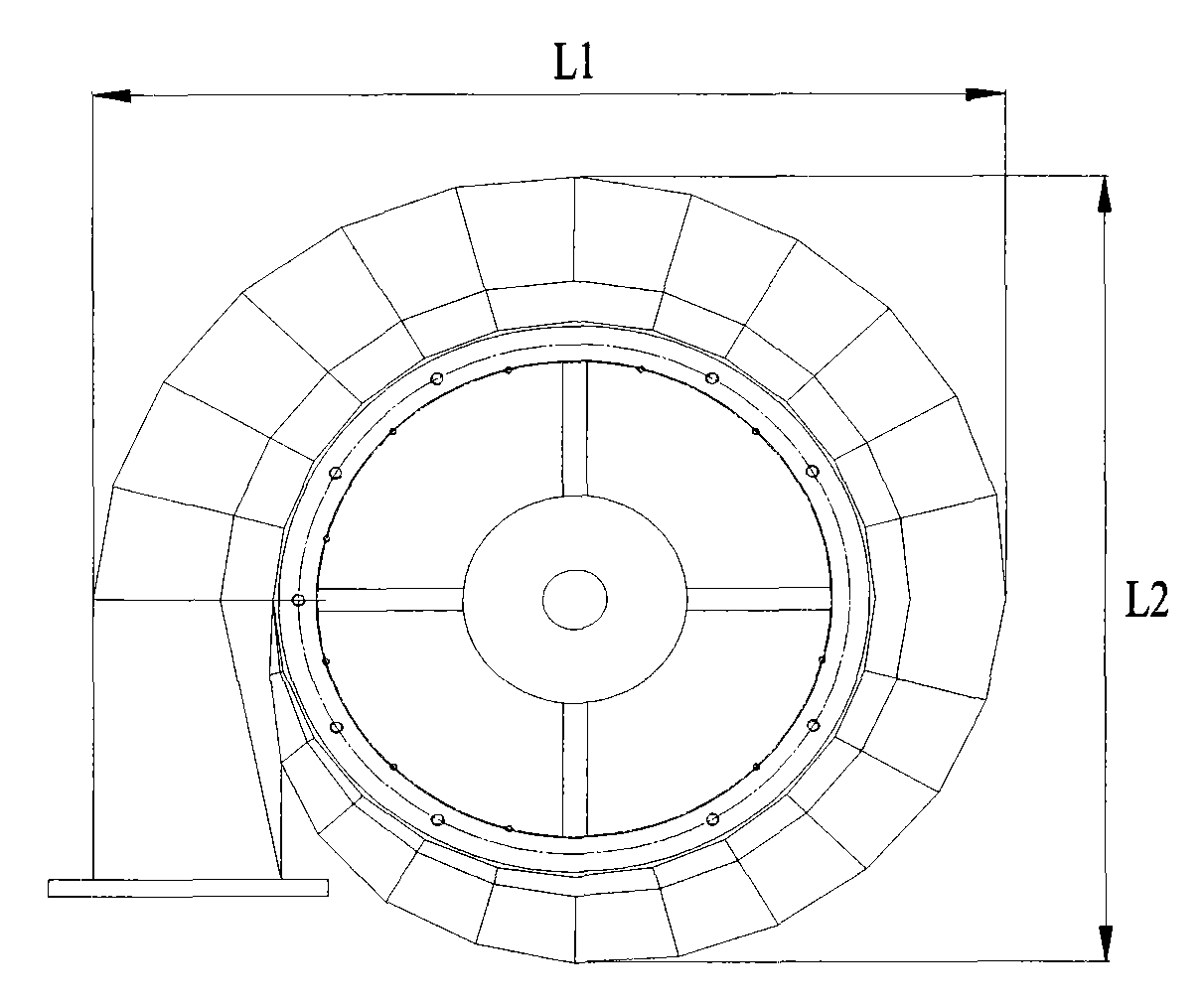

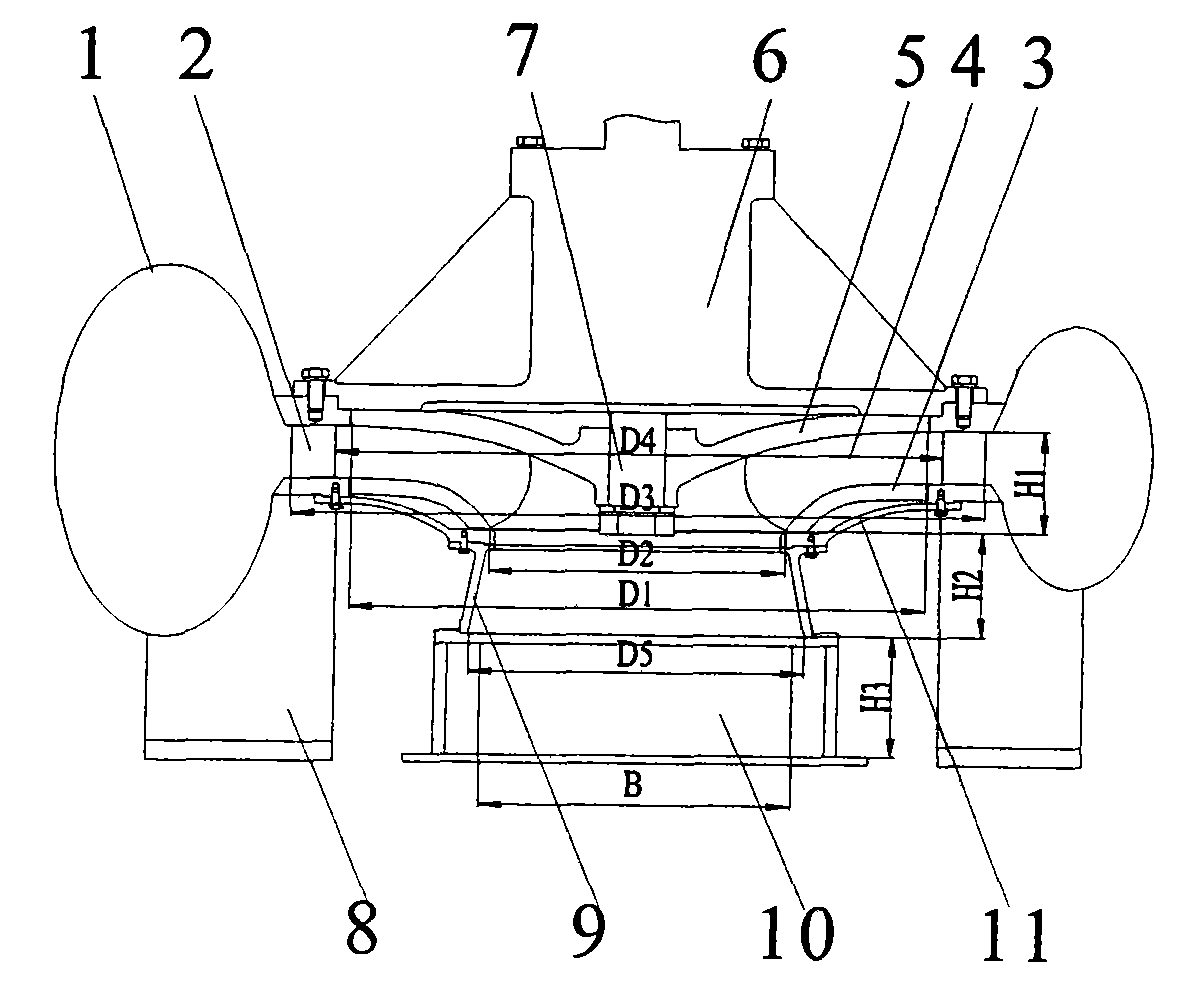

[0029] Such as Figure 1-5 shown.

[0030] A direct-connected low-speed small Francis turbine applied to a hydrodynamic energy-saving cooling tower, which includes an elliptical water inlet cross section ( image 3 ) or trapezoidal ( figure 1 ) metal volute 1, a seat ring 2 with a single row of annular guide vanes, a low-speed Francis turbine runner 12 composed of a lower ring 3, curved blades 4, and an upper crown 5, and a straight cone outlet pipe 9 And a side outlet water tank 10, the seat ring 2 is installed on the inner side of the volute 1, the volute 1 is supported on the pier 8, and the bottom of the runner 12 is equipped with a manifold 11, such as figure 1 As shown, the water inlet between the guide vanes in the seat ring 2 communicates with the water outlet channel of the volute 1, the water inlet of the volute 1 communicates with the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com