A method for obtaining process parameters of resistance seam welding and a welding method

A technology of resistance seam welding and process parameters, applied in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficulty in obtaining welding process parameters, and achieve the effect of avoiding splashing, avoiding belt breakage accidents, and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A welding method, using a narrow lap welder to carry out resistance seam welding on the weldment, the weldment can use various steel materials, such as cold-rolled strip steel, hot-rolled strip steel and galvanized strip steel, etc., in this embodiment, The weldments are made of cold-rolled strip steel.

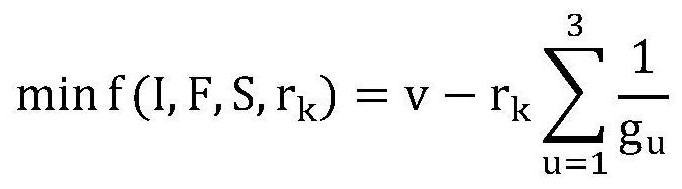

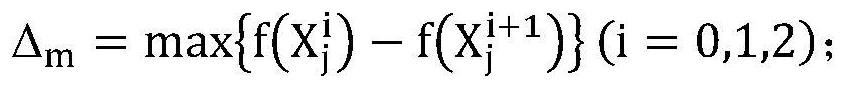

[0036] Among the process parameters of resistance seam welding, welding current I, electrode pressure F and overlap S have been given. Under this condition, the fastest welding speed can be solved by the following steps:

[0037] Based on the finite element method, a narrow lap resistance seam welding temperature field / stress field calculation module is established. In this embodiment, a narrow lap resistance seam welding temperature field / stress field calculation module is established in the SYSWELD finite element analysis software. The specific steps as follows:

[0038] Step a, according to the size of the cold-rolled strip, the size of the roller electrode and the...

Embodiment 2

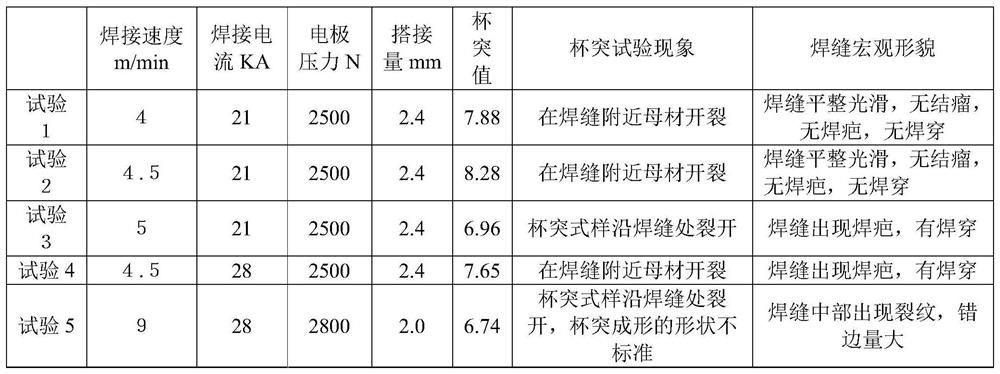

[0054] A welding method, using a narrow lap welder to perform resistance seam welding on the weldment. In this embodiment, the narrow lap welder uses a Siemens ML21M narrow lap resistance seam welder, and its welding capacity: welding current I is not greater than 41KA, the electrode pressure F is not greater than 3000N, and the overlap S is not less than 1.0mm; the weldment to be welded is DP780 steel in cold-rolled strip steel, and its thickness δ=2.21mm.

[0055] Resistance seam welding process parameters include welding speed v, welding current I, electrode pressure F and overlap S.

[0056] Among them, the welding speed v determines the heat release time of the weld. When the welding speed v increases, in order to obtain enough heat, the welding current I must be increased; the size of the welding current I determines the penetration rate of the nugget and Overlap amount, when the welding current I exceeds a certain value, continuing to increase the current can only incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com