Anti-deflection start-up method of annealing furnace

An annealing furnace and bending technology, which is applied in the anti-bending field of annealing furnaces, can solve problems such as strip wrinkling and deformation, and achieve the effect of improving the quality of strip steel and avoiding defects that are easy to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention solve the technical problem of easy warping in the prior art by providing a start-up method for preventing warping of an annealing furnace, and realize the technical effect of avoiding the occurrence of warping defects and improving the quality of strip steel.

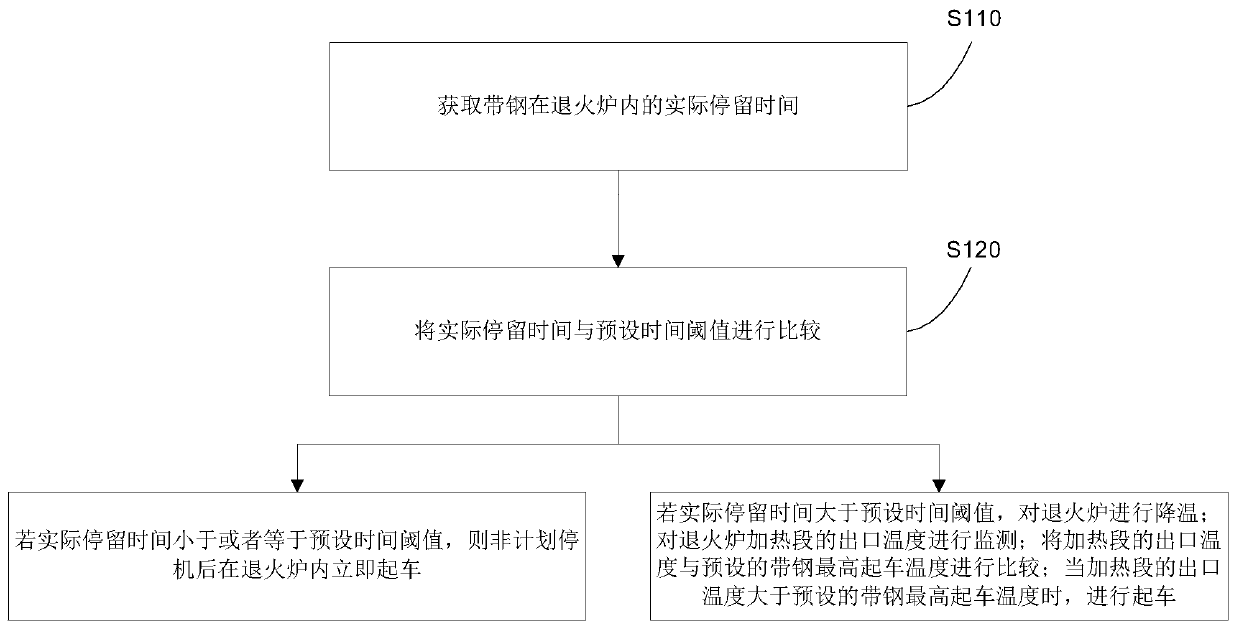

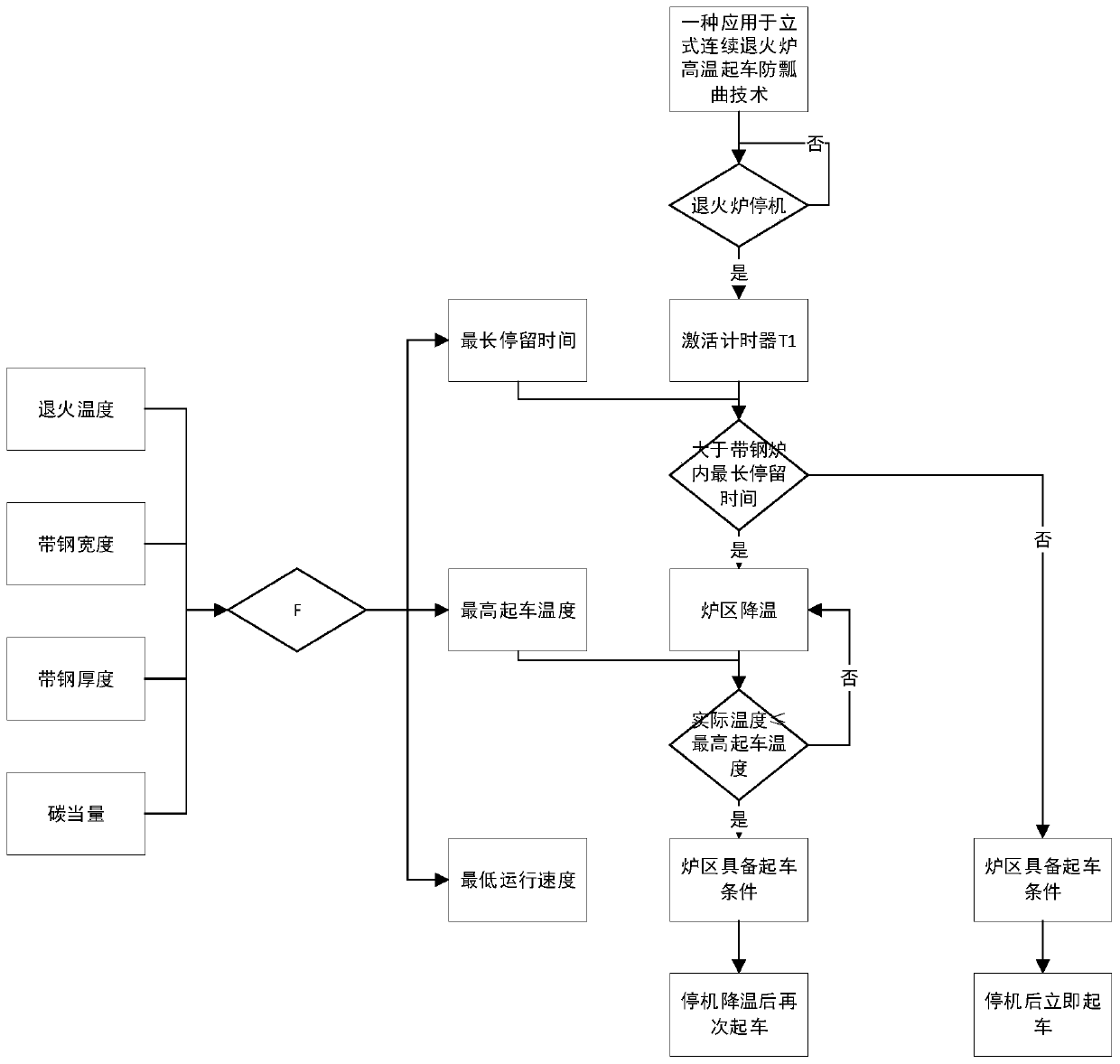

[0036] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

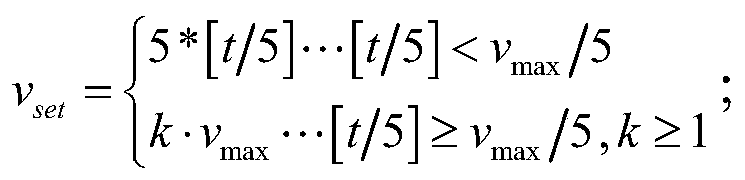

[0037] First obtain the actual residence time of the strip steel in the annealing furnace, and then compare the actual residence time with the preset time threshold; Start up in the annealing furnace immediately after a planned shutdown. In order to avoid the "bending" defect on the surface of the strip due to the increase in the temperature difference between the strip and the furnace roll due to the continued decrease of the strip temperature, the furnace area adopts "extremely speed-up" operation until the strip speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com