Stone plastic floor

A stone-plastic floor and stone-plastic technology, applied in the field of stone-plastic floor, can solve problems such as deformation and warping, achieve the effect of improving product qualification rate and avoiding deformation and warping defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

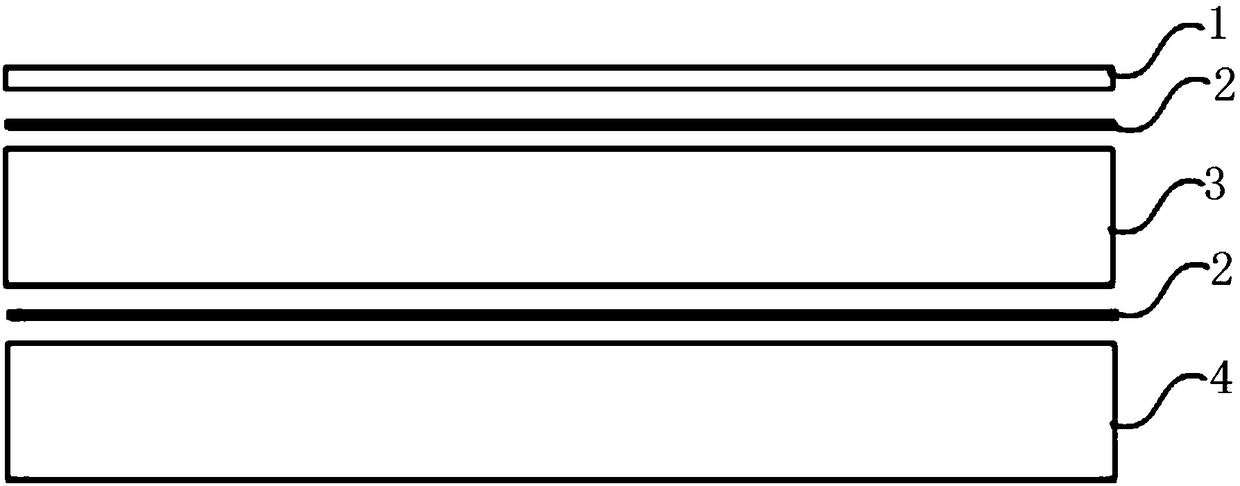

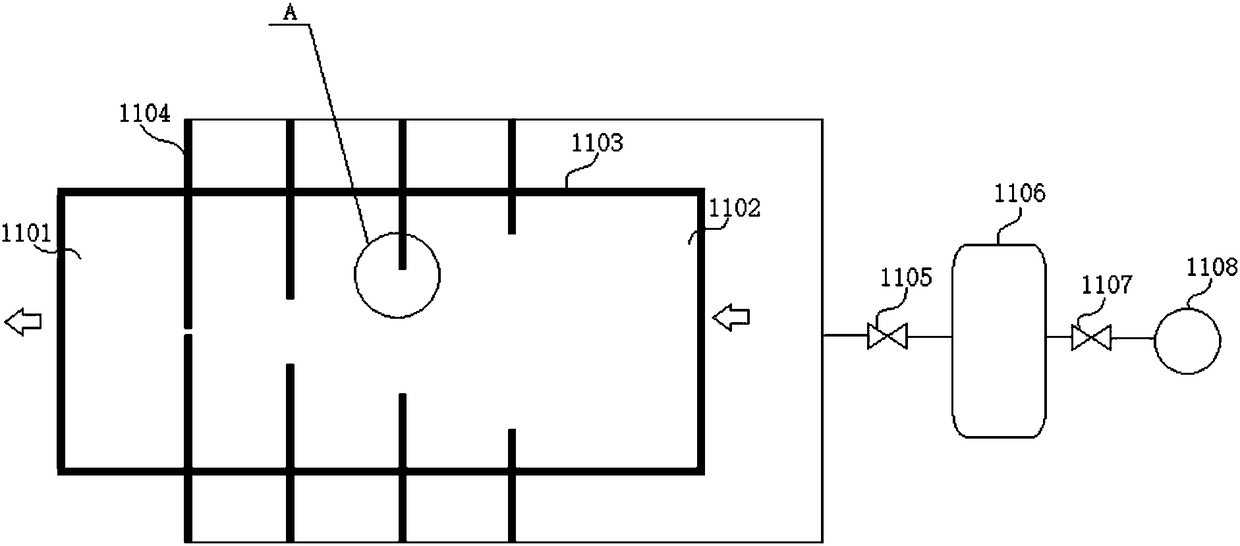

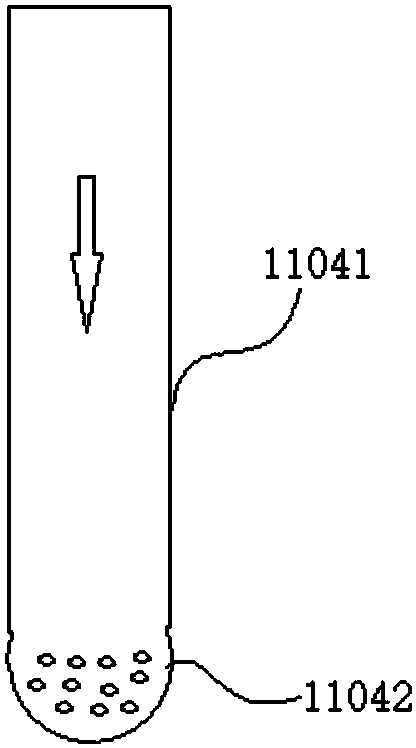

[0035] combine figure 1 , the anti-processing and deformation PVC stone-plastic flooring of the present embodiment includes a decorative layer 1, a PVC stone-plastic base layer 3 and a balance layer 4 from top to bottom, wherein the upper and lower surfaces of the PVC stone-plastic base layer 3 are respectively provided with The heat insulation layer 2, specifically in this embodiment, the heat insulation layer 2 is a material that can withstand a temperature above 100° C. for more than 10 seconds.

[0036] The molecular weight of industrially produced PVC is generally in the range of 50,000 to 110,000, with a large polydispersity, and the molecular weight increases with the decrease of the polymerization temperature; there is no fixed melting point, it starts to soften at 80 to 85°C, and becomes viscoelastic at 130°C , 160~180℃ began to change into a viscous flow state. When using traditional hot-pressing technology to produce PVC stone-plastic flooring, the heat is easily di...

Embodiment 2

[0040] The structure of the anti-processing and deformation PVC stone-plastic floor of this embodiment is basically the same as that of Embodiment 1, furthermore, the decorative layer 1 includes decorative paper, and the upper surface of the decorative paper is pasted with an aluminum oxide wear-resistant layer, wherein the aluminum oxide The two-aluminum wear-resistant layer has the advantages of super wear-resistant, high elasticity, super impact resistance, fire retardant, waterproof and moisture-proof, sound-absorbing and noise-proof, and realistic patterns.

Embodiment 3

[0042] The structure of the anti-processing and deformation PVC stone-plastic floor of this embodiment is basically the same as that of Embodiment 1, furthermore, the decorative layer 1 includes decorative paper, and the decorative paper is a decorative spray-coated paper whose upper surface is sprayed with aluminum oxide. The decorative spray paper coated with aluminum oxide on the surface is used as the decorative layer 1, which simplifies the processing technology of the PVC stone-plastic floor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com