Steel strip and aluminium strip automatic storage machine

An aluminum tape, automatic technology, applied in the field of aluminum tape automatic storage machine and steel, can solve the problems of increasing the production cost of optical cable, broken tape, waste of human resources, etc., to save production cost and human resources, reduce production cost, use Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

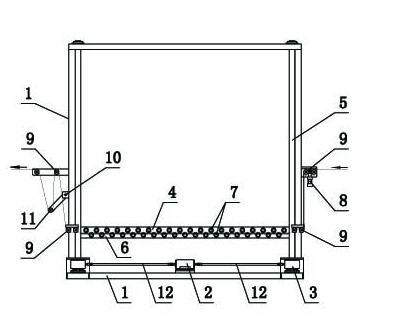

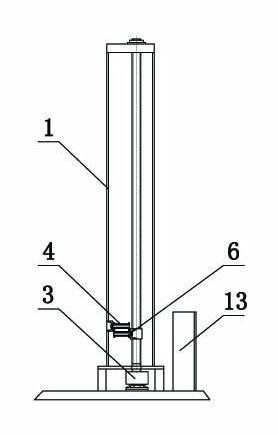

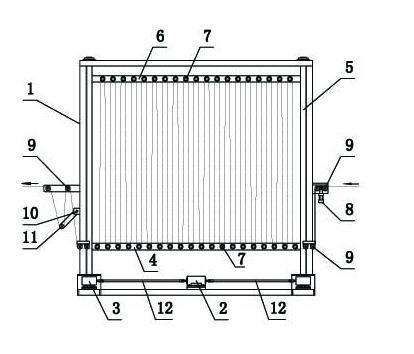

[0013] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings:

[0014] The steel and aluminum belt automatic storage machine is composed of frame 1, motor 2, transmission 3, fixed bracket 4, screw 5 and movable bracket 6. Frame 1 is a four-sided frame structure, and the middle of the base of frame 1 is fixed with a motor 2. Both ends of the base are equipped with transmission 3 respectively. Motor 2 and transmission 3 are connected by drive shaft 12. The lower part of the inner side of the left and right sides of the frame 1 is fixed with a fixed bracket 4, and both ends of the fixed bracket 4 are installed There are pulley 9. Screws 5 are installed on the left and right columns of the frame 1. The lower end of the screw 5 is connected with the output shaft of the transmission 3. The screw 2 is equipped with a movable bracket that can move up and down when the screw 2 rotates; the fixed bracket 4 Rotating guide whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com