Method for controlling deviation of wide materials of continuous annealing unit

A continuous annealing unit and wide material technology, which is applied in the field of steel rolling heat treatment, can solve the problems that cannot be eliminated, scratches on the unit frame and furnace wall, material strip inlet loops, deviation in the furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

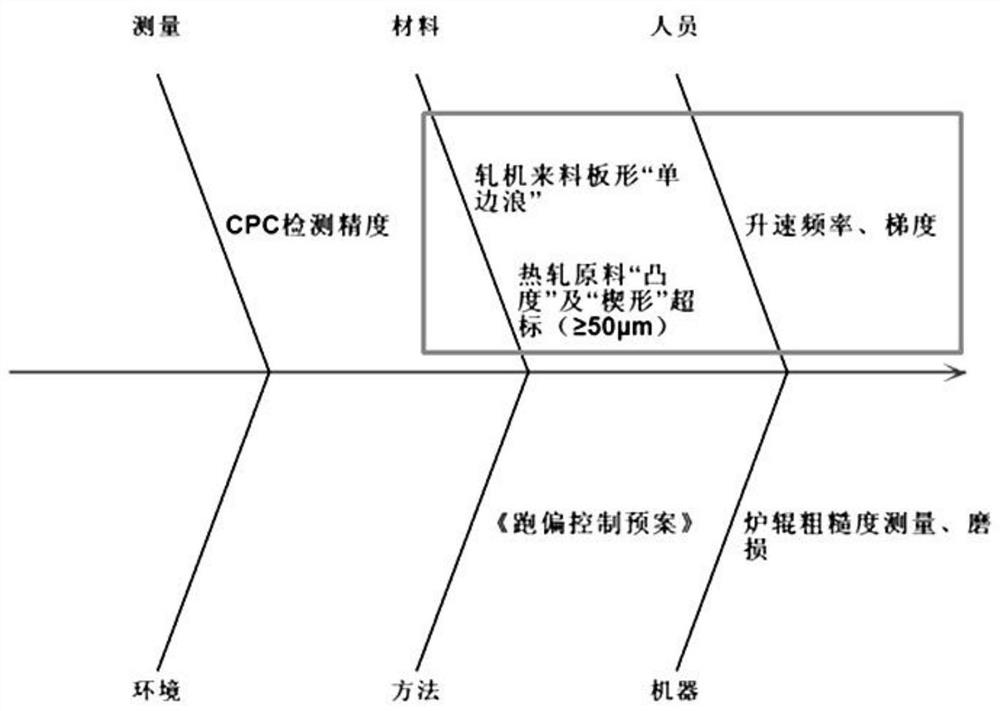

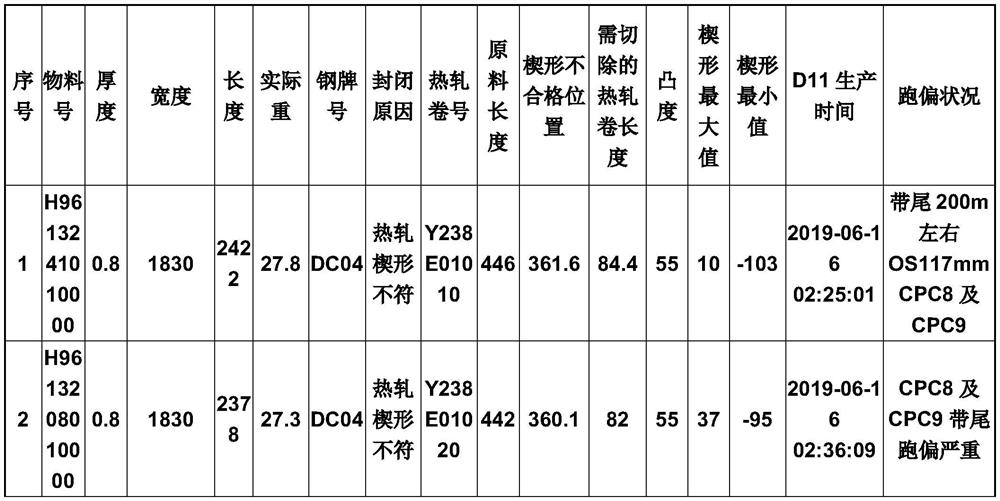

[0015] Factors affecting strip deviation such as figure 1 As shown, for "strip deviation in continuous stripping" from human (operation), machine (measurement and wear of furnace roll surface roughness), material (rolling mill incoming material plate shape and "hot rolling raw material convexity, wedge shape exceeding standard"), Carry out cause analysis and comparison of existing measures in terms of method ("Deviation Control Plan"), ring and measurement (CPC detection accuracy), find out the real reason affecting the "strip deviation" of the 2130 continuous retreat unit in the current stage, and take corresponding measures Give a solution.

[0016] Bad influence of plate shape: H99030120, DC04, 1.6mm×1500mm, produced by the continuous retreating unit at 18:51:28 on September 14, 2019, the strip steel deviated 215mm from the entrance looper to the OS side and scratched the "looper frame", and the team stopped Cut off the deviation and scratched part. According to the video...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com