Fabricated steel belt elevator counterweight rack

A counterweight frame and assembled technology, which is applied in the direction of elevators, transportation and packaging, elevators, etc. in buildings, and can solve the problems of high welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

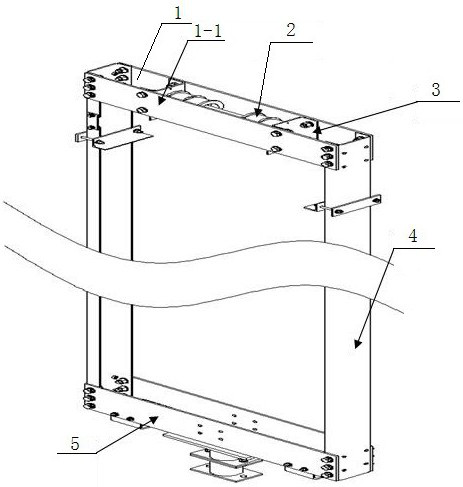

[0031] Such as Figure 4-7 , take WG (counterweight guide gauge) = 900, take the counterweight frame size 866x2800 mm (the distance between the upper edge of the upper beam device 1 and the lower edge of the lower beam device 5 is 2800mm; the length of the upper and lower beam devices is 866mm), vertical beam 4 The thickness of the upper and lower beams is 53mm, the thickness of the upper and lower beams is 160mm, and the size of the rectangle ABCD formed by the diagonals of the counterweight frame is 760x2480 mm;

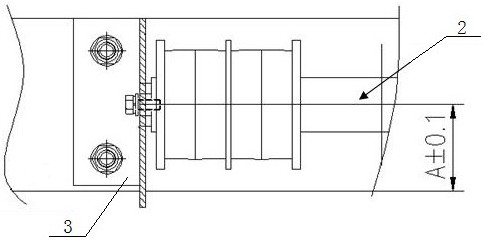

[0032] The guide pulley mounting plate 3 adopts laser blanking to ensure that the deviation of the vertical distance A between the guide pulley device 2 and the lower edge of the upper beam device 1 is within ±0.1, and the length of the guide pulley device 2 is greater than 200mm, then the guide pulley device 2 and The parallelism of the upper beam device 1 is 0.2 / 200 or 0.1, which can ensure that the piece guide pulley device 2 and the upper beam device 1 have a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com