Soft-measuring method for tension of band steel between rollers of continuous annealing unit

A soft measurement and tension technology, applied in tension measurement and other directions, can solve the problems of not considering the influence of the overall inertia, unstable strip characteristics, model errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] First, make a unified description of the symbols in each drawing:

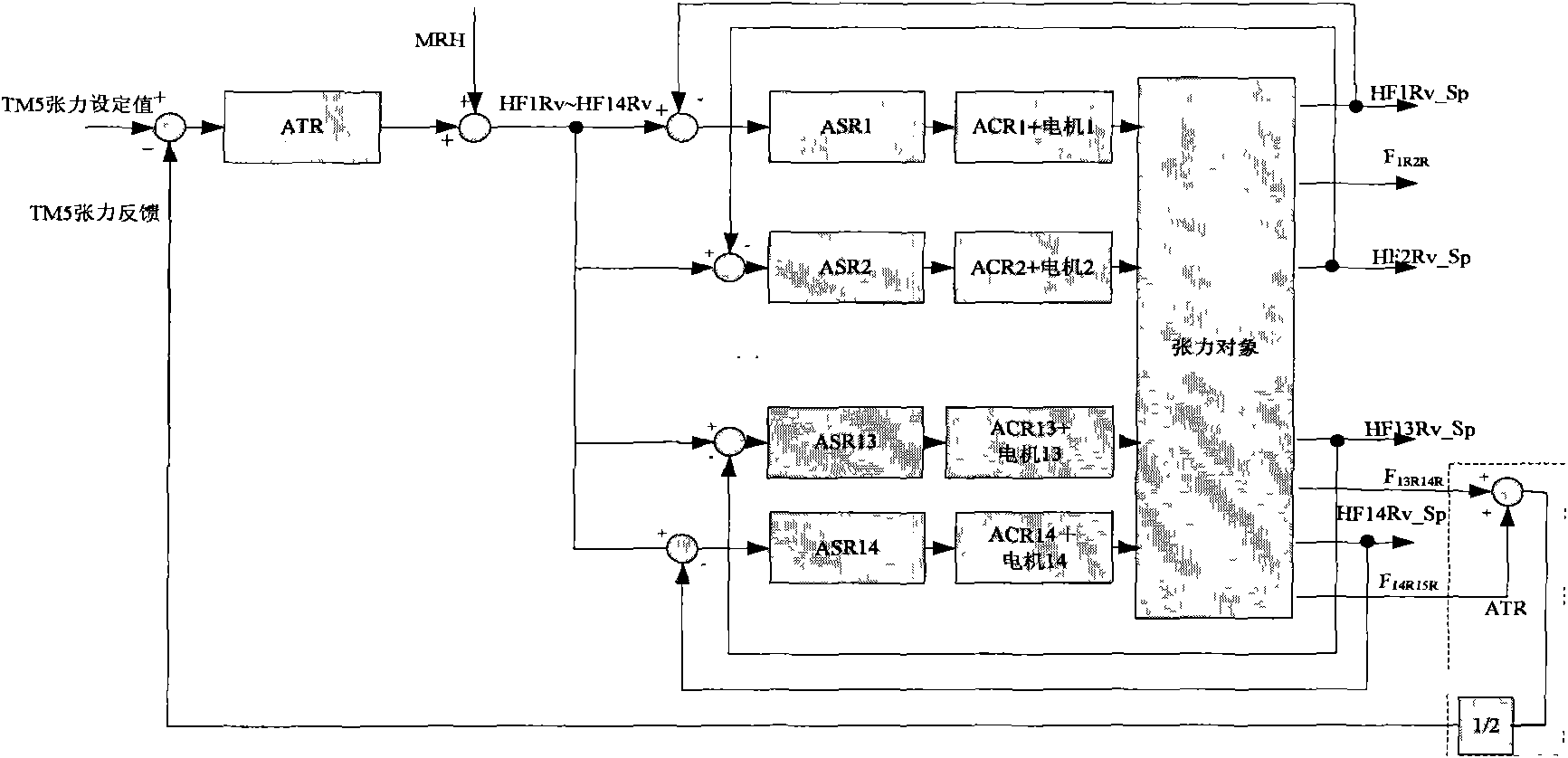

[0087] figure 1 Symbols are explained as follows:

[0088] TM5 is No. 5 tension measuring instrument MRH-reference speed ATR-tension ring controller

[0089] ACR1~ACR14-current loop 1~current loop 14

[0090] ASR1~ASR14-speed loop controller 1~speed loop controller 14

[0091] HF1Rv_Sp~HF14Rv_Sp-HF Furnace No. 1 roll speed measured value ~ HF Furnace No. 14 roll speed measured value

[0092] HF1Rv~HF14Rv-HF Furnace No.1 Roller~HF Furnace No.14 Roller Speed Measured Setting Value

[0093] f 1R2R ~F 14R15R -Inter-roll tension of No. 1 roll, No. 2 roll to No. 14 roll, No. 15 roll;

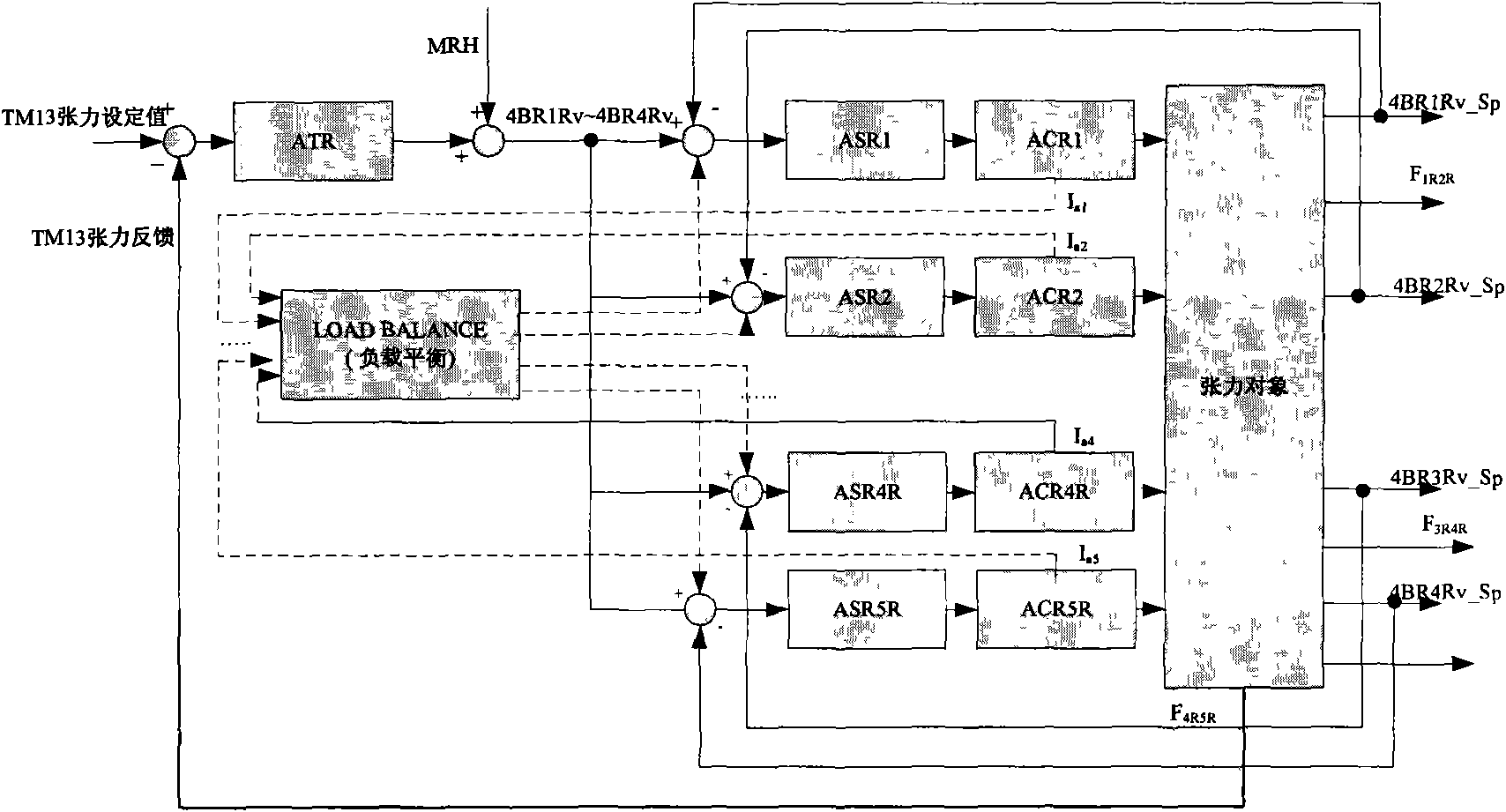

[0094] Figure 2a Symbols are explained as follows:

[0095] ACR1~ACR5-Current circulator 1~Current loop 5

[0096] ASR1~ASR5-speed loop controller 1~speed loop controller 5

[0097] LOAD BALANCE - load balancing algorithm

[0098] 4BR1Rv_Sp~4BR5Rv_Sp-No. 4 Tension Roll No. 1 Roll Speed Measured Value ~ No. 4 Tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com