Soft-measuring method for tension of band steel between rollers of continuous annealing unit

A technology of soft measurement and tension, applied in the direction of tension measurement, etc., can solve the problems of unstable strip steel characteristics, model errors, and difficult to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

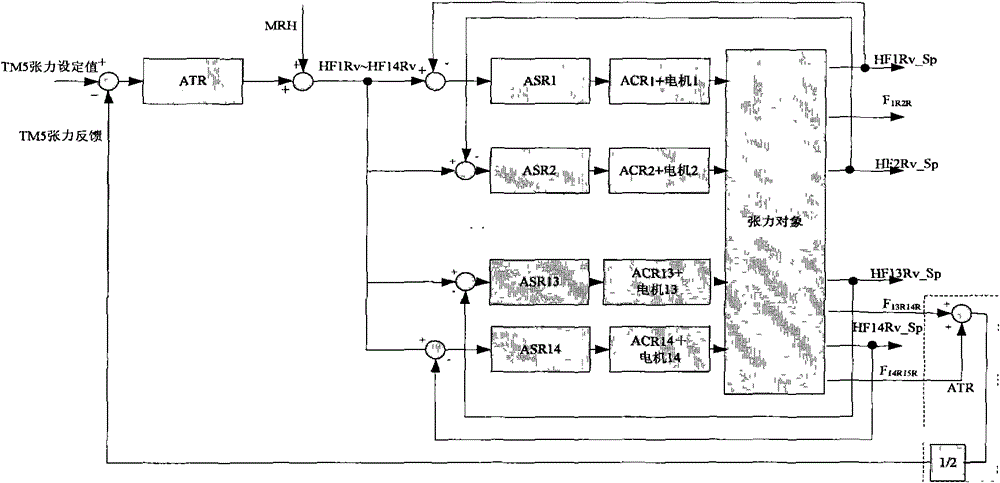

[0086] First, make a unified description of the symbols in the drawings:

[0087] figure 1 The symbols in the description are as follows:

[0088] TM5 is No. 5 tension measuring instrument MRH-reference speed ATR-tension ring controller

[0089] ACR1~ACR14-current loop 1~current loop 14

[0090] ASR1~ASR14-Speed loop controller 1~Speed loop controller 14

[0091] HF1Rv_Sp~HF14Rv_Sp-HF furnace No. 1 roll speed measured value ~ HF furnace No. 14 roll roll speed measured value

[0092] HF1Rv~HF14Rv-HF furnace No. 1 roll ~ HF furnace No. 14 roll speed measured setting value

[0093] F 1R2R ~F 14R15R -1 Roller No. 2 roller to No. 14 roller No. 15 roller tension;

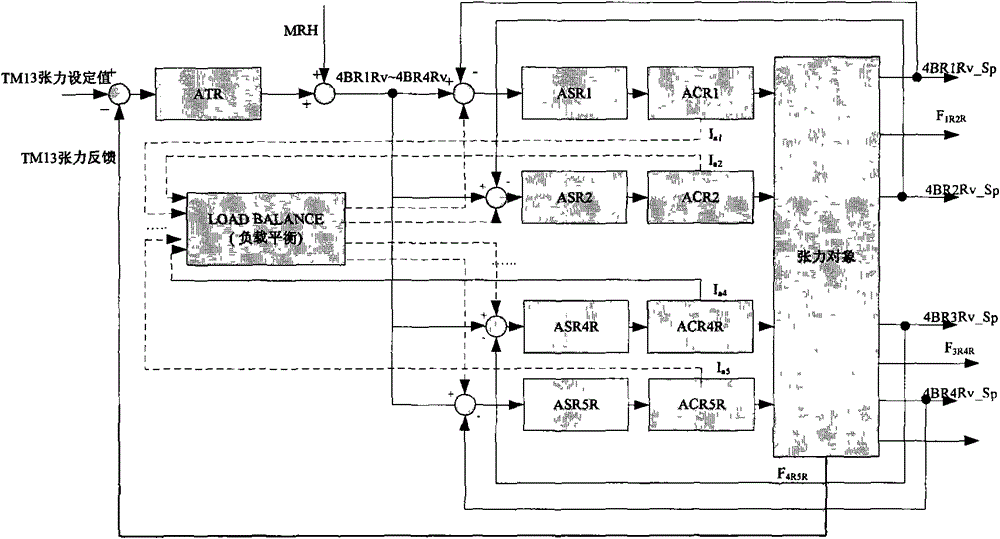

[0094] Figure 2a The symbols in the description are as follows:

[0095] ACR1~ACR5-current loop device 1~current loop 5

[0096] ASR1~ASR5-Speed loop controller 1~Speed loop controller 5

[0097] LOAD BALANCE-load balancing algorithm

[0098] 4BR1Rv_Sp~4BR5Rv_Sp-4 Tension roll No. 1 roll speed measured value ~ No. 4 tension rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com