Tension on-line detecting device

A detection device and tension technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of easy judgment errors and achieve the effect of avoiding broken belt accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

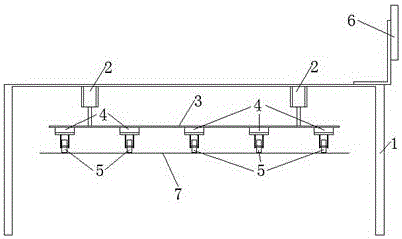

[0009] Depend on figure 1 Known, a tension on-line detection device includes a shelf 1, a cylinder 2, a connecting plate 3, a pressure sensor 4, a roller 5 and a display screen 6; there are two cylinders 2 symmetrically distributed under the table of the shelf 1 , the bottom of the cylinder is fixed on the bottom of the table top of the shelf 1, and the head of the piston rod is connected on the connecting plate 3; several groups of pressure sensors 4 and rollers 5 evenly distributed are arranged below the connecting plate 3, and the described The connecting plate 3 is made of stainless steel with a thickness greater than 1 cm; the above pressure sensor 4 is fixed on the connecting plate, and the bottom is connected to the base of the roller 5; the upper right of the shelf 1 is also provided with a 6 on the display screen.

[0010] When working, after the cylinder 2 is inflated, the piston rod drives the connecting plate 3 to press down, the roller 5 presses on the cold-rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com