Breakage protection device for belt conveyor

A belt conveyor and protection device technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as loss, achieve the effects of preventing heavy loads from slipping, facilitating reuse, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

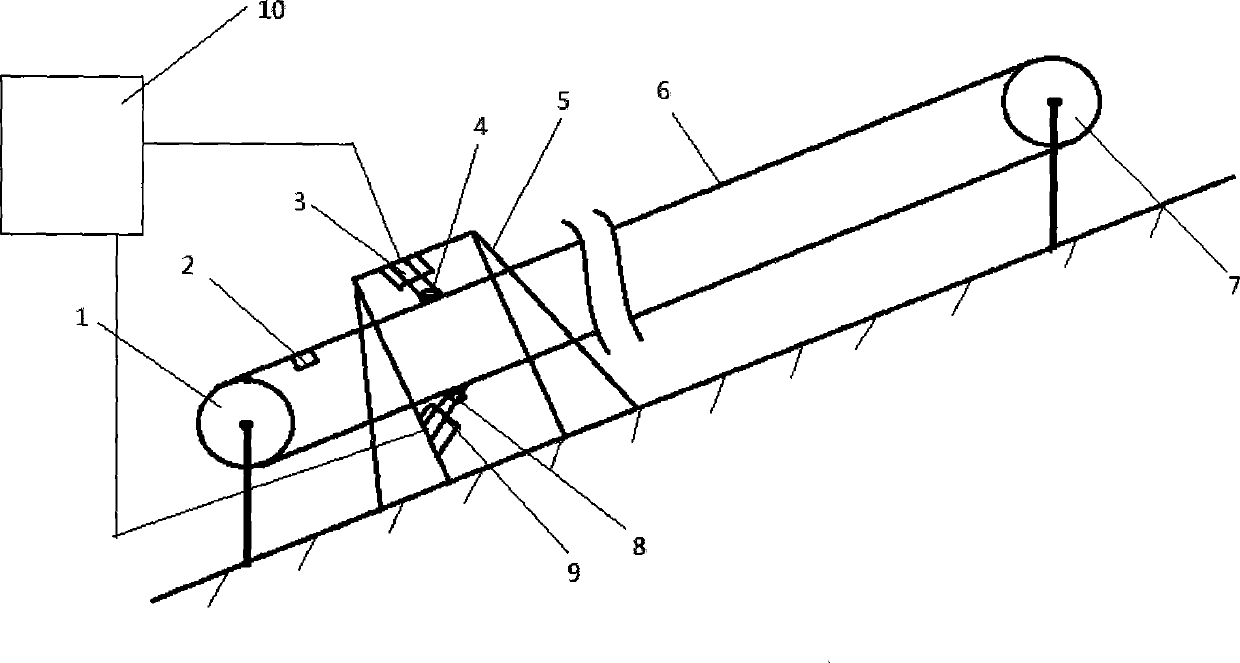

[0017] Such as figure 1 As shown, a broken belt protection device for a belt conveyor includes a driving drum 1, a reversing drum 7 and a conveyor belt 6 sheathed between them, and the conveyor belt 6 is erected 80 meters above the driving drum There is a support 5, and an upper extrusion beam 4 perpendicular to the upper end surface of the conveyor belt is arranged in the middle of the support 5, and the other end of the upper extrusion beam 4 is connected with the piston end of the upper hydraulic cylinder 3; There is a lower extruding beam 8 for extruding the lower end surface of the conveyor belt 6, and the other end of the lower extruding beam 8 is connected to the piston end of the lower hydraulic cylinder 9; the upper hydraulic cylinder 3 and the lower hydraulic cylinder 9 respectively pass through oil pipes It is connected with the hydraulic pump station 10; the sensor 2 for detecting the reverse operation of the conveyor belt is arranged at intervals below the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com