Control system and control method of dancer roll

A pneumatic control system and control method technology, applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve problems such as broken furnace belt, strip steel broken, accidents, etc., and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

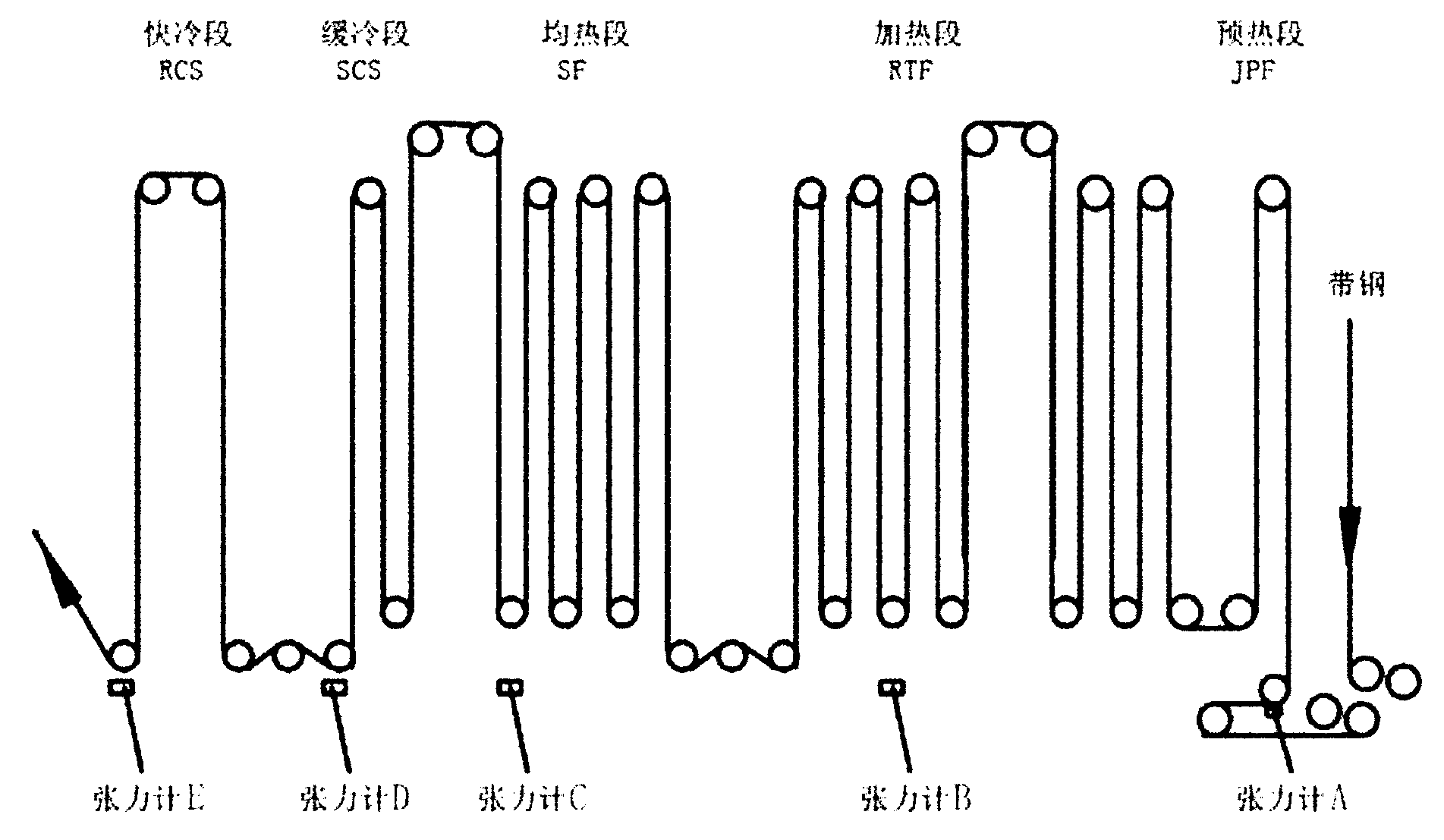

[0062] Such as figure 1 As shown, the equipment in the furnace section of the hot-dip galvanizing unit, the strip passes through the preheating section (JPF), heating section (RTF), soaking section (SF), slow cooling section (SCS), rapid cooling section (RCS) and other equipment , Each section is provided with a corresponding tensiometer A to a tensiometer E for tension testing.

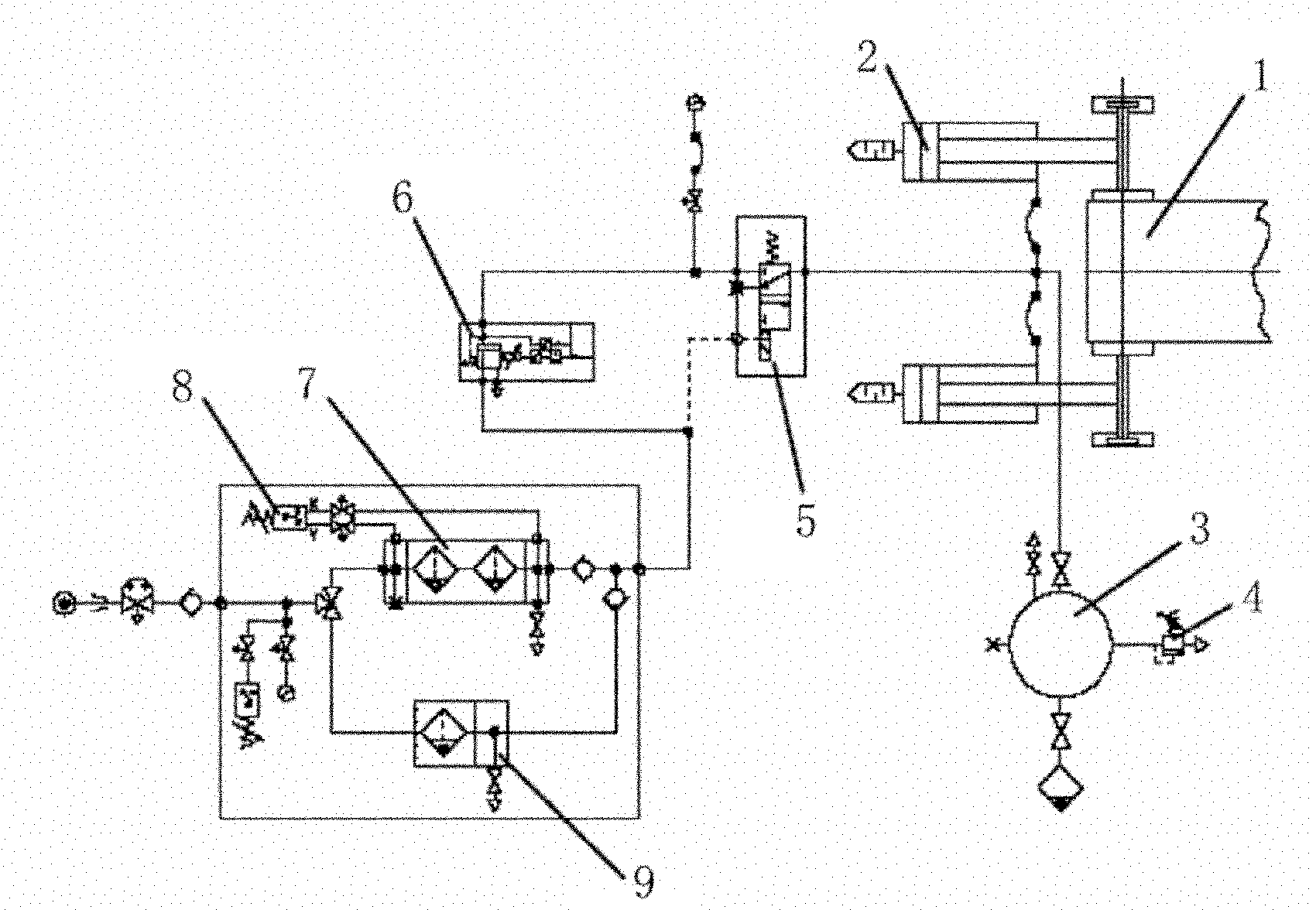

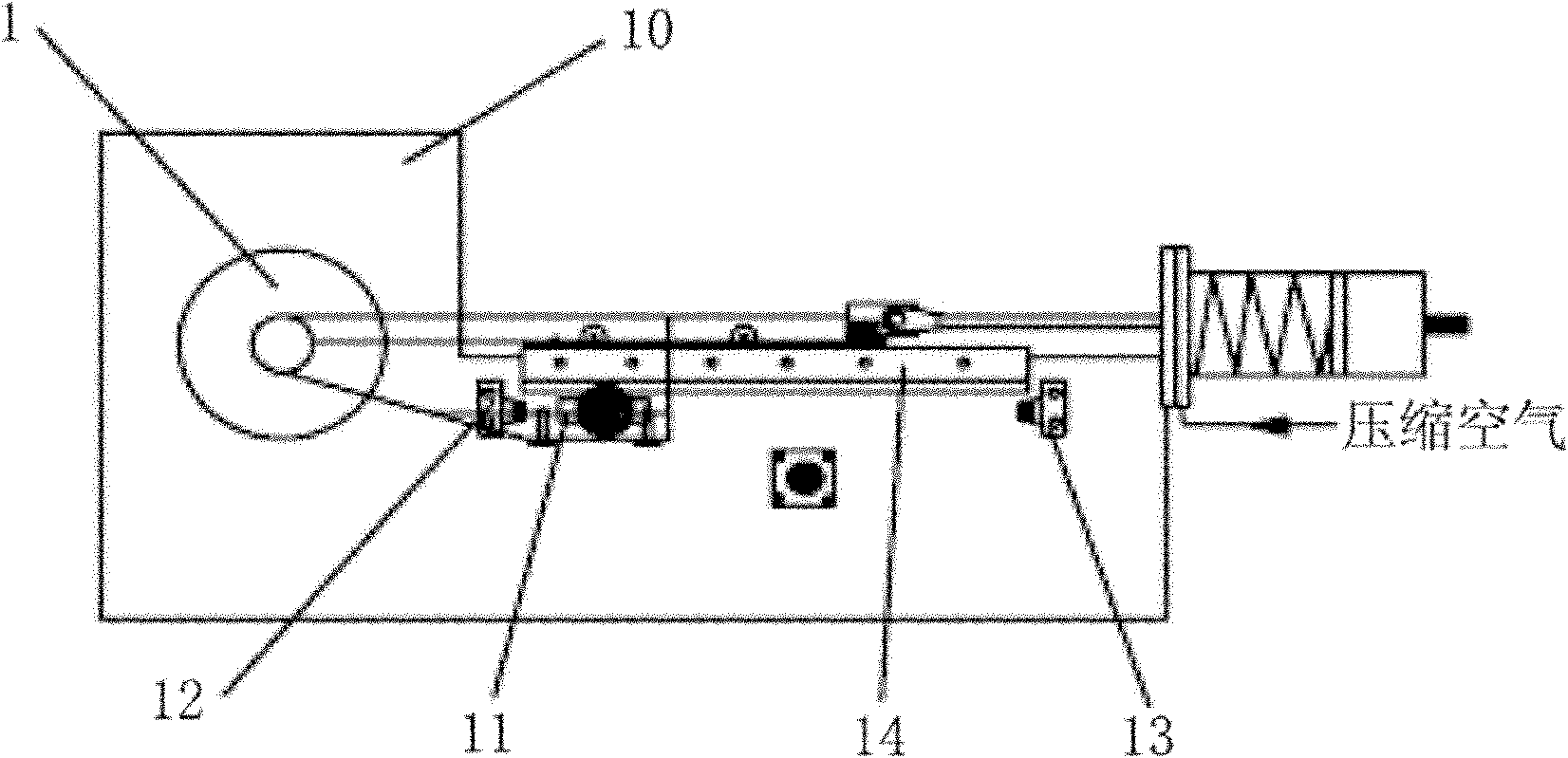

[0063] Aiming at the problems existing in the actual application of the prior art, this dancing roller control system is proposed, such as figure 2 and image 3 As shown, the dancing roller 1 is installed on a fixed frame 10, and a movable frame is installed on two high-precision rails 14 (the movable frame and the fixed frame 10 are different frames here), and four guide rails are installed. A low inertia dancer roller 1 is supported on this frame of the wheel. The control of the jumping roller adopts a control mode combining tension control as the main and position control as the slave. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com