Device and method for preventing alkali wash section of continuous annealing line from off-tracking

A technology of alkaline washing and deviation, applied in the field of devices for preventing deviation of alkali washing section of continuous withdrawal line, can solve the problems of waste products, inability to produce, deviation of strip steel, etc., to avoid belt breakage accidents, improve production efficiency, The effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

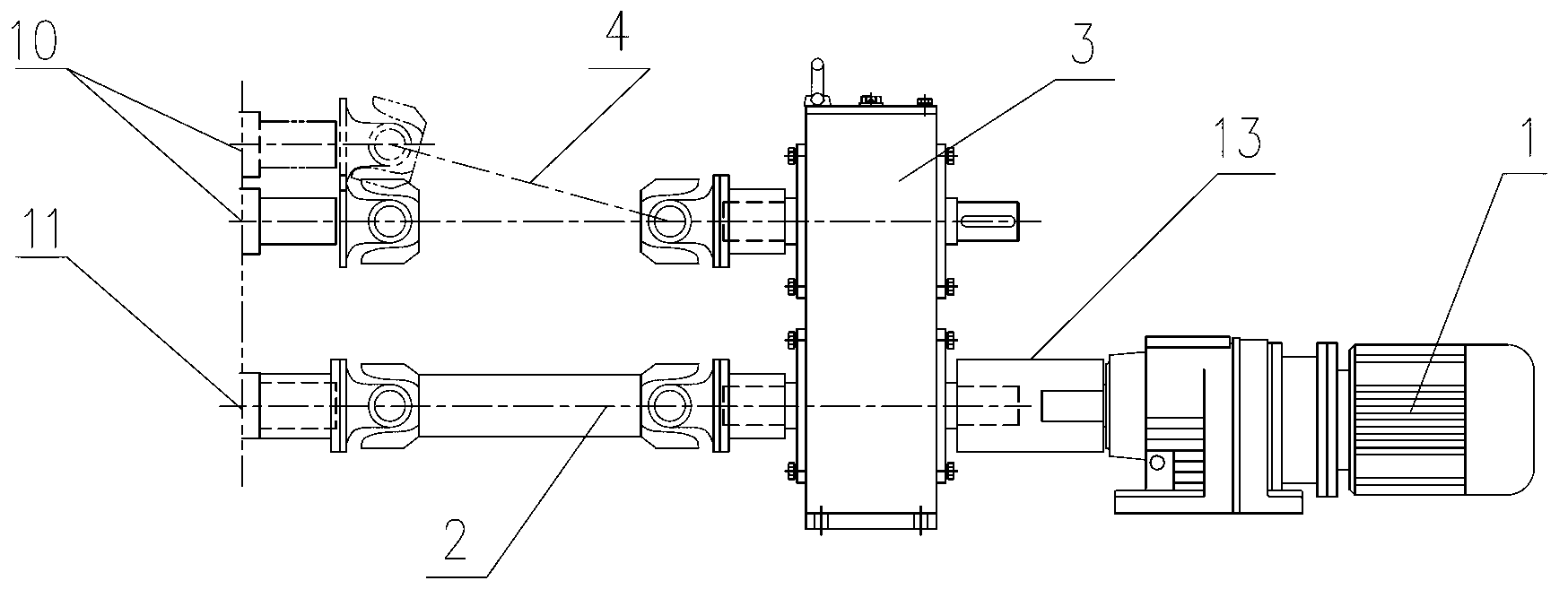

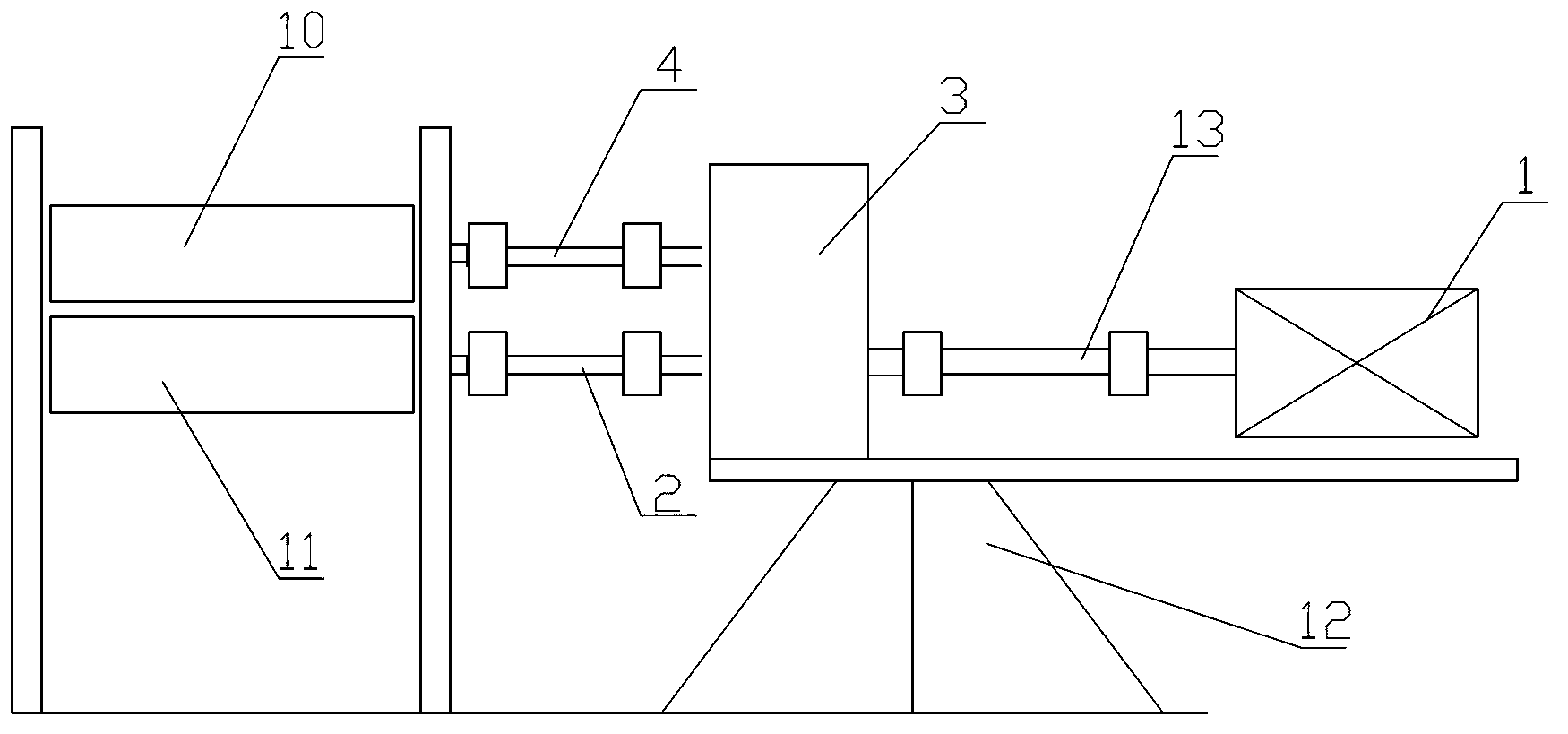

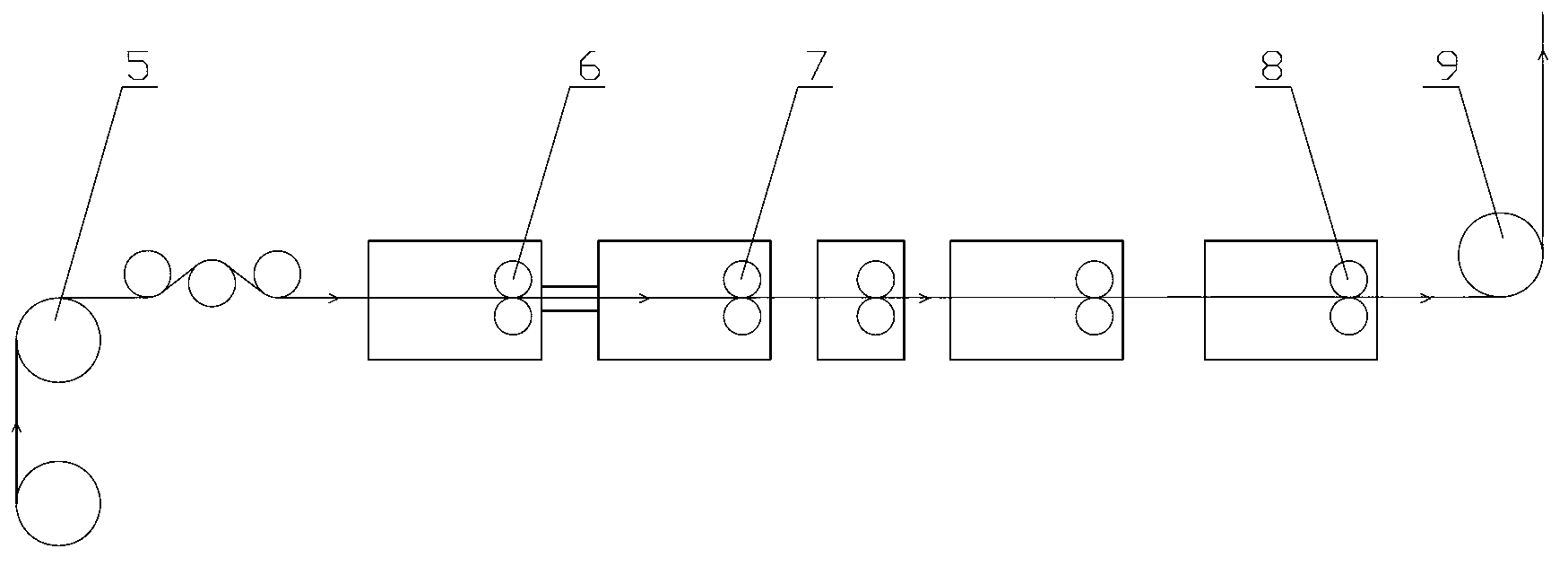

[0027] The device that prevents the deviation of the alkali washing section of the continuous annealing line is installed on the alkali spray squeeze roller 6 and the alkali brush squeeze roller 7. Taking the alkali spray squeeze roller 6 as an example, on the upper and lower sides of the alkali spray squeeze roller 6 The ends of the squeezing rollers 10 and 11 are connected to the two output ends of the gear box 3 through the ball cage coupling one 4 and the ball cage coupling two 2 , and the input end of the gear box 3 is connected to the output end of the variable frequency motor 1 . The upper and lower squeeze rolls 10, 11 of the alkali spray squeeze roll 6 are driving rolls like this. Alkali brush squeezes dry roll 7 identical with alkali spray squeeze dry roll 6, when strip steel passes through like this, just can not take place the phenomenon of skidding.

[0028] The invention prevents the deviation of the steel strip in the alkali washing section, reduces the waste of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com