Automatic-control rubber belt hydraulic tightening device

A tensioning device and hydraulic technology, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of insufficient hydraulic tension control accuracy, inability to change randomly, and adjust tension, etc., to achieve compact structure, stable and reliable starting, and avoid breakage. Bring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

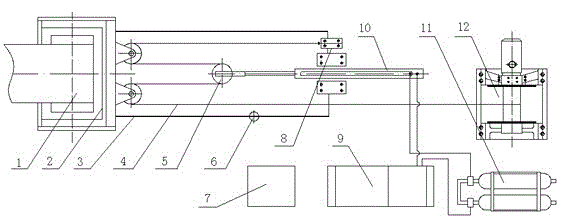

[0011] Such as figure 1 As shown, the tape self-control hydraulic tensioning device, the main components include a hydraulic pump station 9, a control box 7, a tensioning oil cylinder 10 and an energy storage station 11, and a control host, a digital control circuit and a random function module are arranged in the control box. Both the control circuit and the random function module are connected with the control host.

[0012] Wherein, the tensioning oil cylinder 10 is an actuator during normal operation, and the steel wire rope 4 is connected to the tensioning trolley 2 through the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com