Zn-Zr intermediate alloy and preparation method and application thereof

An intermediate alloy, zn-zr technology, applied in the field of metal alloy materials, can solve the problems of reduced mechanical properties, high melt reaction temperature, complex process, etc., and achieve the effects of reducing production costs, reducing melting temperature, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

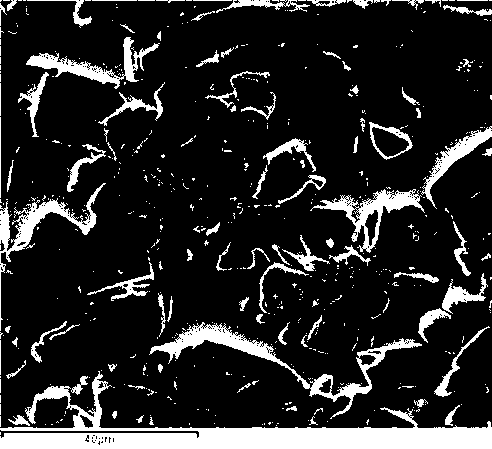

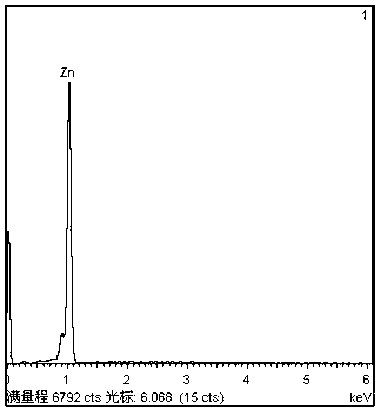

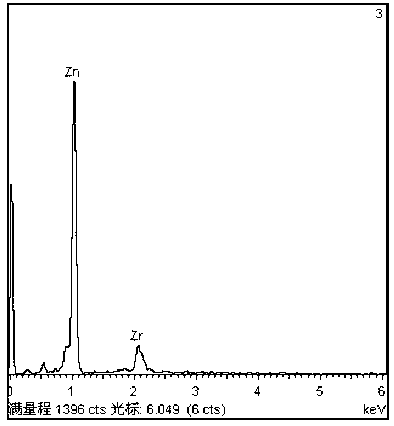

[0031] To prepare 5 kg of Zn-10wt.%Zr master alloy, weigh 4.5 kg of pure zinc and 0.5 kg of pure zirconium (average particle size 5mm). Use an intermediate frequency induction furnace to melt pure zinc to 660-740°C, then add pure zirconium into the zinc melt in two batches, and continue heating for 3-8 minutes after adding each batch. The zinc-zirconium alloy melt that has been reacted is fully stirred to make the components uniform. Then it is poured into the casting mold, and after solidification, the Zn-10Zr master alloy is obtained, and block Zn-Zr compounds are distributed in the matrix zinc (see appendix figure 1 Chinese SEM organization chart and attached figure 2 and 3 EDX spectrum).

[0032] The above-mentioned Zn-10Zr master alloy is added to the hypoeutectic Zn-3Al alloy melt at 460°C at a ratio of 0.5wt.% for 10 minutes and then poured, which can make the primary η-Zn grains of the Zn-3Al alloy solidified Significant refinement is obtained: before refinement, ...

Embodiment 2

[0035] To prepare 10 kg of Zn-5wt.%Zr master alloy, weigh 9.5 kg of pure zinc and 0.5 kg of pure zirconium (average particle size 3mm). Use an intermediate frequency induction furnace to melt pure zinc to 630-730°C, then add pure zirconium to the zinc melt at one time, and continue heating and reacting for 2-7 minutes after adding. The zinc-zirconium alloy melt that has been reacted is fully stirred to make the components uniform. Then it is poured into the mold, and after solidification, the Zn-5Zr master alloy is obtained.

[0036] Adding the above Zn-5Zr master alloy to the hypoeutectic Zn-3Al and hypereutectic Zn-50Al alloys can achieve the same grain refinement effect as the Zn-10Zr master alloy in Example 1.

Embodiment 3

[0038] To prepare 10 kg of Zn-3wt.%Zr master alloy, weigh 9.7 kg of pure zinc and 0.3 kg of pure zirconium (average particle size 7mm). Use an intermediate frequency induction furnace to melt pure zinc to 660-760°C, then add pure zirconium to the zinc melt at one time, and continue heating for 1-5 minutes after adding. The zinc-zirconium alloy melt that has been reacted is fully stirred to make the components uniform. Then it is poured into the mold, and after solidification, the Zn-3Zr master alloy is obtained.

[0039] Adding the above-mentioned Zn-3Zr master alloy to the hypoeutectic Zn-3Al and hypereutectic Zn-50Al alloys can achieve the same grain refinement effect as that of the Zn-10Zr master alloy in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com