Light transmission plate and panel lamp

A technology of light-transmitting plate and panel light, which is applied in the direction of light source fixing, lighting device, and components of lighting device, etc., can solve the problems of increasing cost, increasing lens, and making the thickness of the backlight source thinner, so as to reduce the demand space. , Improve the utilization rate of light energy, increase the effect of using places and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

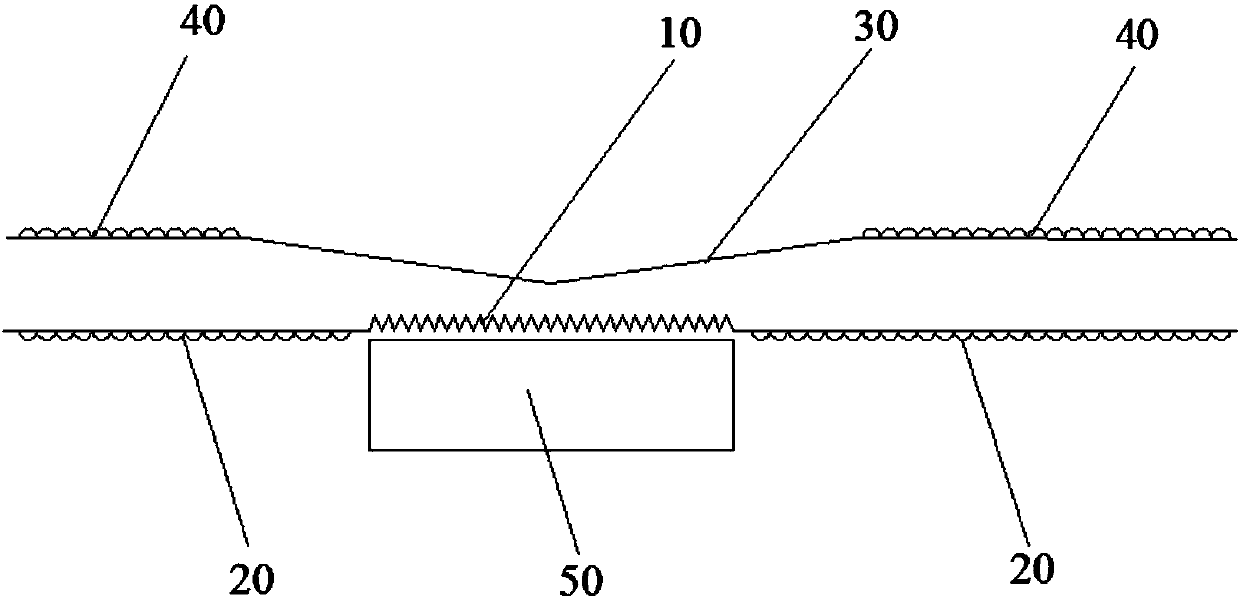

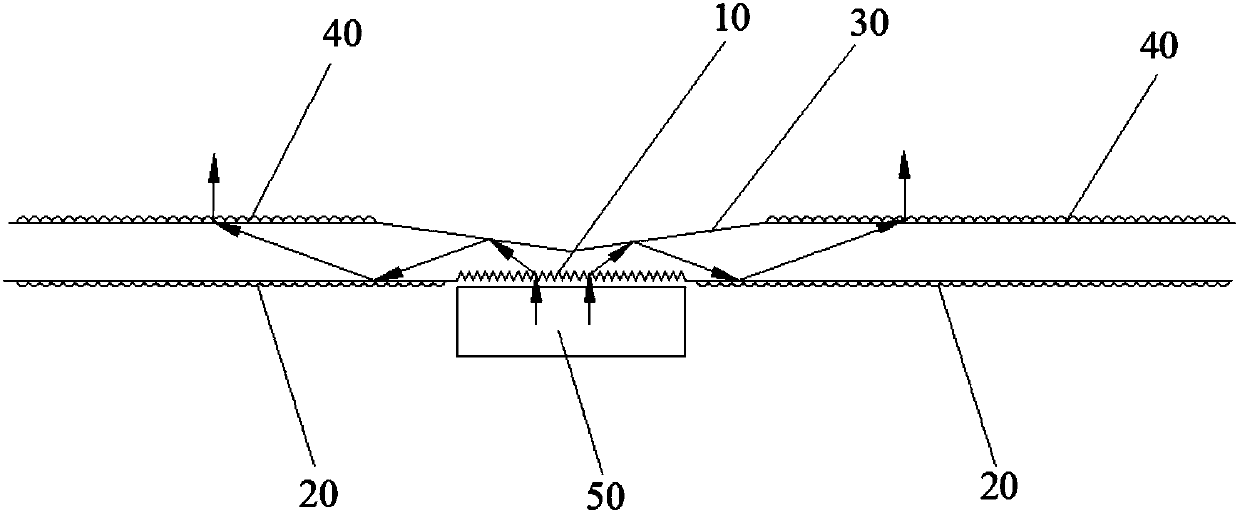

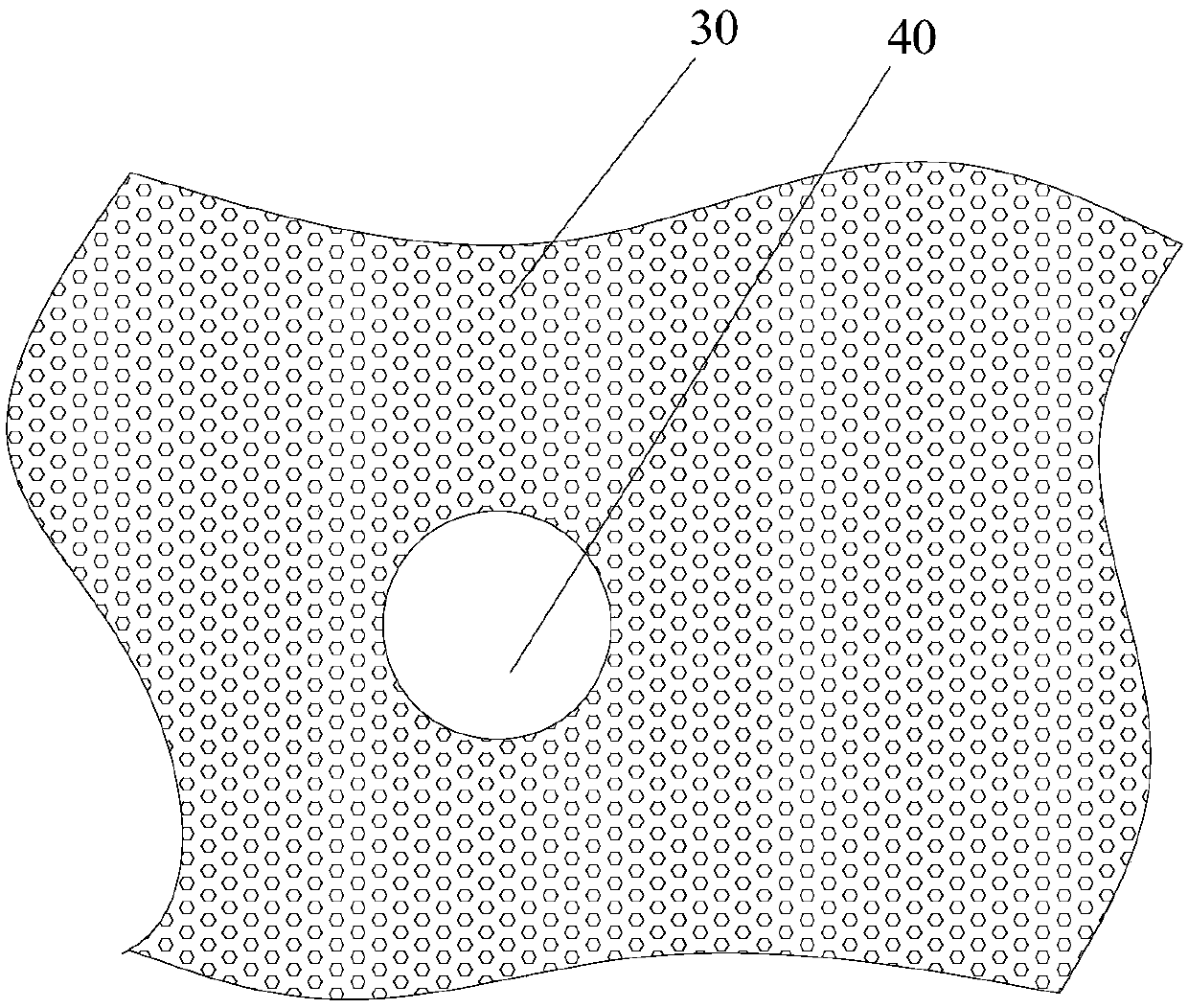

[0028] Such as Figure 1 to Figure 5 As shown, the light-transmitting plate of the present application, in one embodiment, the lower surface of the light-transmitting plate is provided with an optical scattering structure 10 and an optical reflection structure 20, and the upper surface of the light-transmitting plate is provided with an optical polarization structure 30 and an optical focusing structure. Structure 40. In the present application, the lower surface of the light-transmitting plate is the light incident end, and the upper surface of the light-transmitting plate is the light-emitting end. The optical reflective structure 20 surrounds the optical scattering structure 10, the optical polarizing structure 30 cooperates with the optical scattering structure 10, the optical concentrating structure 40 surrounds the optical polarizing structure 30, the light-transmitting plate can be used to be installed on the optical path, and the optical The scattering structure 10 co...

Embodiment 2

[0036] The panel light of the present application includes a light source 50 and a light-transmitting plate. Such as Figure 1 to Figure 5As shown, in one embodiment, an optical scattering structure 10 and an optical reflection structure 20 are provided on the lower surface of the transparent plate, and an optical polarizing structure 30 and an optical concentrating structure 40 are provided on the upper surface of the transparent plate. In the present application, the lower surface of the light-transmitting plate is the light incident end, and the upper surface of the light-transmitting plate is the light-emitting end. The optical reflective structure 20 surrounds the optical scattering structure 10, the optical polarizing structure 30 cooperates with the optical scattering structure 10, the optical concentrating structure 40 surrounds the optical polarizing structure 30, the light-transmitting plate can be used to be installed on the optical path, and the optical The scatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com