Composite masonry wall

A masonry wall and wall technology, applied in the structural field of building composite masonry walls, can solve the problems of poor seismic and shear resistance, inability to give full play to the compressive bearing capacity of plastered surfaces, unfavorable building earthquake resistance, etc., to achieve The effect of reducing construction cost, increasing shear resistance, and increasing indoor usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

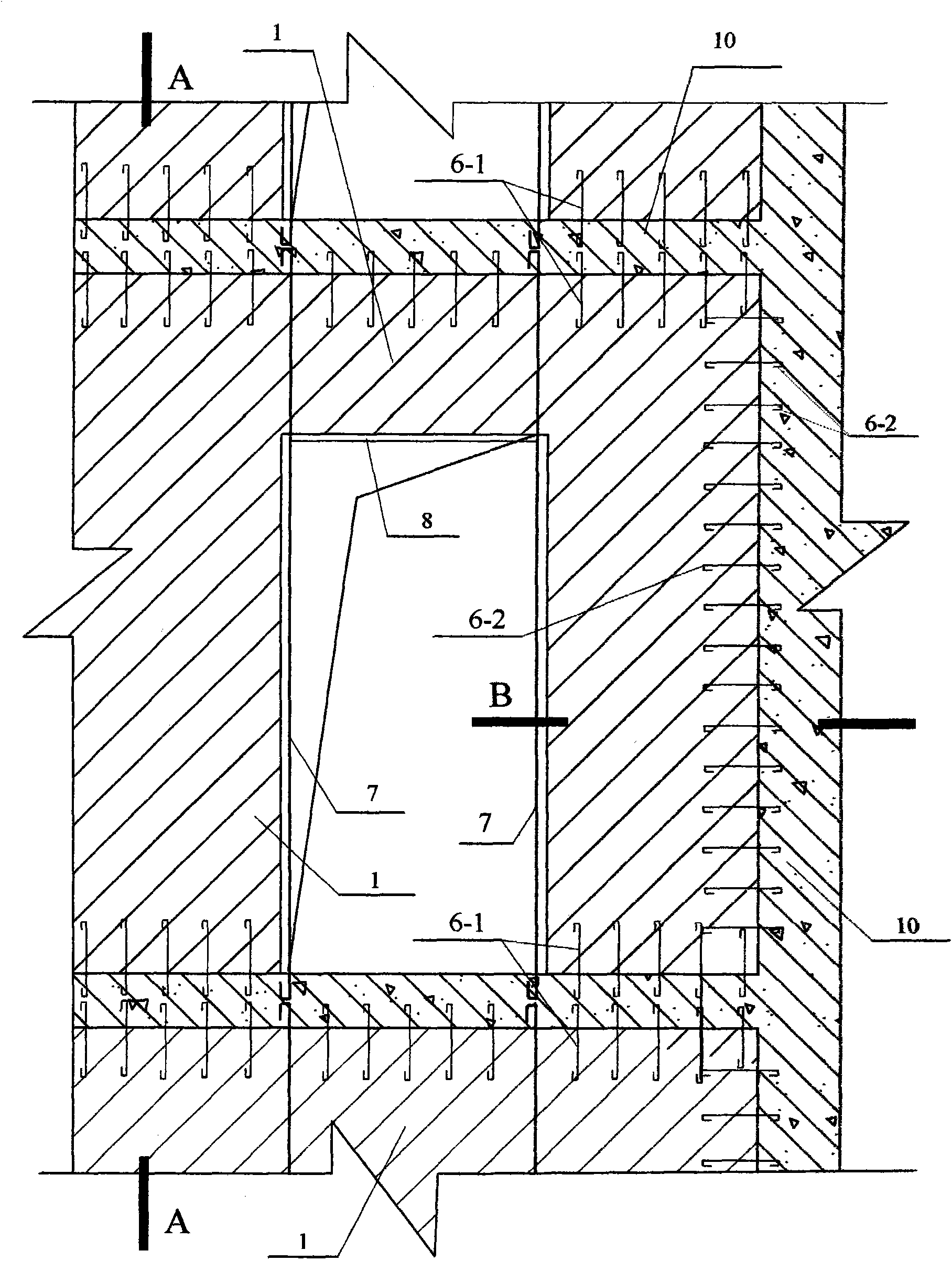

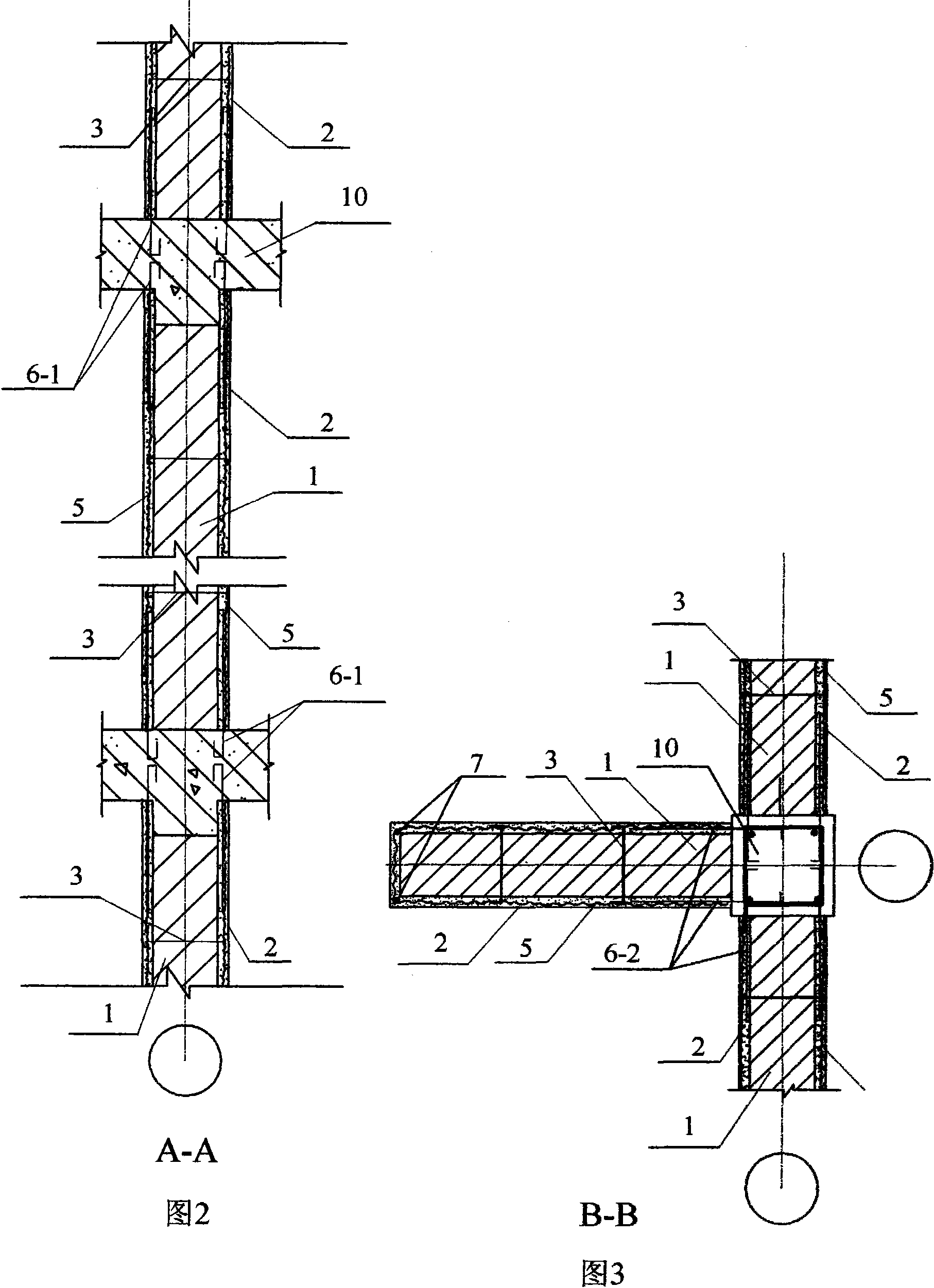

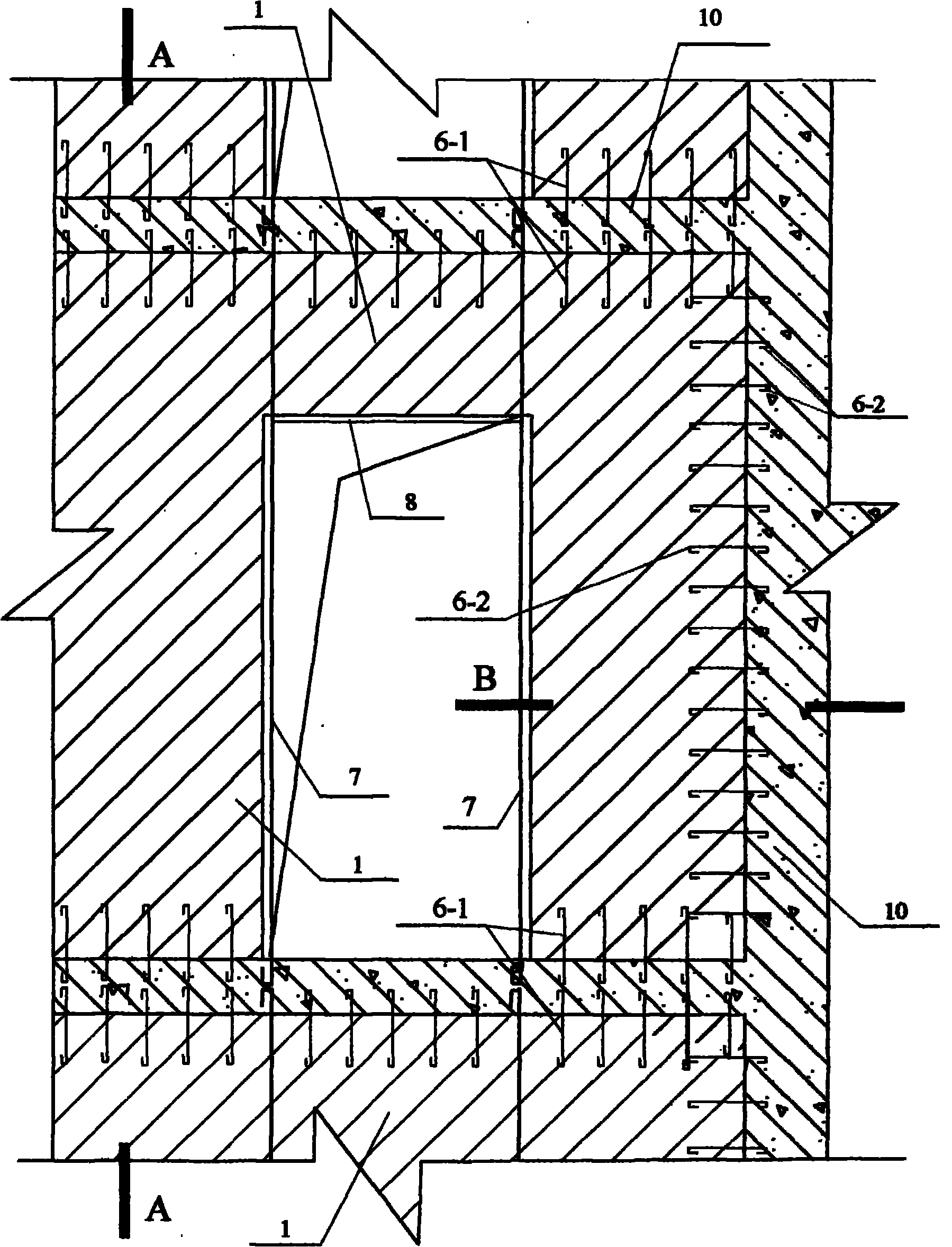

[0011] Specific implementation mode one: see Figure 1 ~ Figure 3 , a combined masonry wall of the present embodiment is composed of a masonry wall 1, an outer plastering layer 2, a tensioned steel bar 3, a mesh tensile material 5, a vertical anchoring steel bar 6-1, and a main building structure 10; The masonry wall 1 is a load-bearing masonry; the outer plastering layer 2 is a cement mortar surface layer or a fine stone concrete surface layer, or a modified cement mortar surface layer or a concrete surface layer; the mesh tensile The material 5 is an alkali-resistant mesh cloth 5-1 or a metal mesh 5-2 or a bamboo reinforcement mesh 5-3; the main building structure 10 is a beam or a plate or a column or a wall of a concrete or steel-concrete combination or a steel structure; the The tensioned steel bar 3 is located in the mortar layer of the masonry wall 1, the tensioned steel bar 3 passes through the plane of the masonry wall 1 vertically, and the tensioned steel bar 3 and t...

specific Embodiment approach 2

[0017] Specific implementation mode two: see figure 1 , image 3 The difference between this embodiment and the first embodiment is that this embodiment adds a horizontal anchoring steel bar 6-2, and the horizontal anchoring steel bar 6-2 is combined with the concrete or steel-concrete structure of the building main structure 10 or the column or steel structure The wall is anchored, and the horizontal anchoring steel bar 6-2 is overlapped with the mesh tensile material 5 .

[0018] The composite masonry wall of Embodiment 1 or 2 is a composite masonry provided with vertical and horizontal metal wires (or alkali-resistant mesh cloth or bamboo reinforcement mesh), and is connected with the main structure through anchoring steel bars. Under the action of shear force, the steel bars or metal wires (or alkali-resistant mesh or bamboo reinforcement mesh) in the wall are in tension, so the vertical and horizontal wires (or alkali-resistant mesh or bamboo reinforcement mesh) can play...

specific Embodiment approach 3

[0019] Specific implementation mode three: see Figure 1 ~ Figure 3 , the difference between this embodiment and the specific embodiment 1 or 2 is: the masonry wall 1 of a combined masonry wall in this embodiment is a light-weight filled masonry, forming a light-weight filled masonry with mesh plastering on both sides. Composite masonry walls.

[0020] This embodiment is suitable for lightweight filled walls with frame structures. The lightweight filled composite masonry walls with net plastering on both sides are shear-resistant walls with the ability to resist horizontal displacement, and their shear resistance capacity is (or alkali-resistant mesh or bamboo reinforcement mesh) the shear bearing capacity of the outer plaster layer.

[0021] The outer plastering layer on the overlapping parts of the mesh tensile material and the vertical anchoring steel bars, the outer plastering layer on the overlapping parts of the horizontal anchoring steel bars, and the outer plastering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com