Preparation method for tab-embedded type electrode plate, electrode plate and lithium ion battery

A technology of positive pole piece and negative pole piece, which is applied in the field of lithium-ion battery preparation, can solve the problems of reducing battery energy density, increasing battery thickness, and unqualified battery, so as to reduce internal resistance, increase cycle times, and increase energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

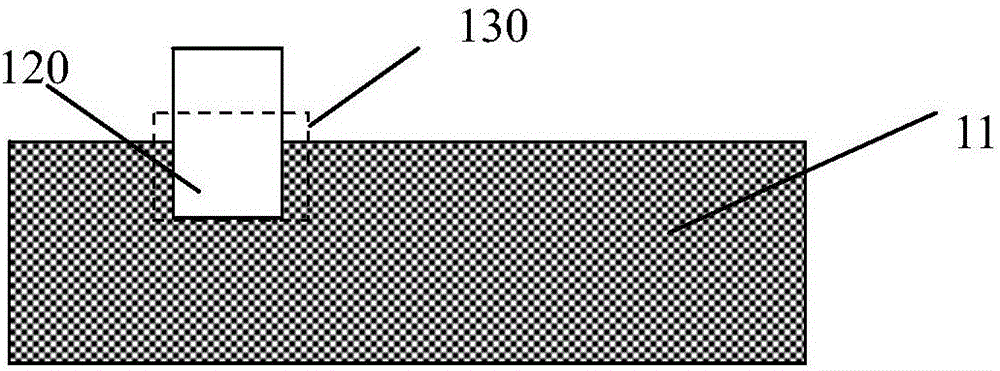

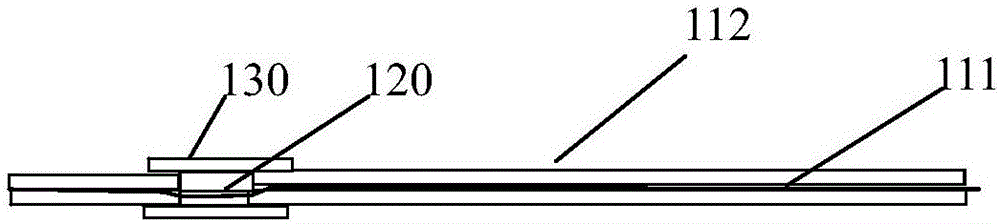

[0042] The preparation method of the wound pole group of the present invention includes the preparation method and the winding method of the buried tab pole piece, wherein the preparation method of the buried tab pole piece comprises the following steps,

[0043] 1) Pre-apply the foam tape on the predetermined position of the current collector, that is, the foil, such as copper foil or aluminum foil. Among them, multiple layers can be applied on one side, or on the front and rear sides of the foil respectively. covered with foam tape,

[0044] 2) Coat the slurry on the pre-attached foam tape foil, and then send it into the oven to dry, while the foam tape begins to thermally detackify and curl, that is, the thermal detackification temperature and curl of the foam tape The temperature should correspond to the drying temperature and drying time of the slurry, that is, the powder. For the foam tape, it is enough to select the corresponding microcapsules and tape components. No fu...

Embodiment 1

[0072] (1) Design buried lugs:

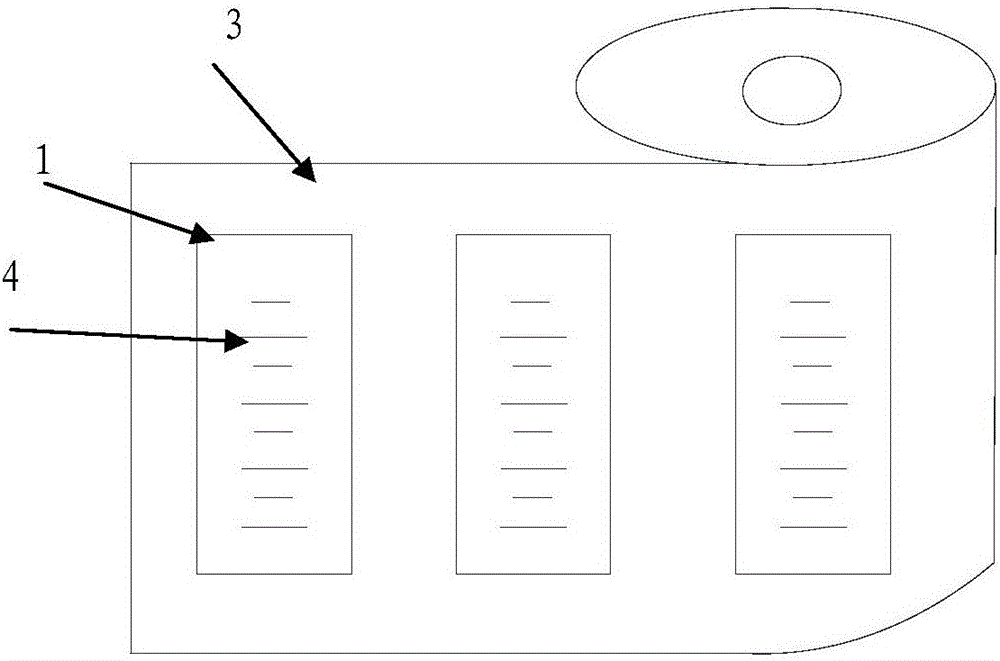

[0073] Carry out battery design according to the size requirements of the battery model. Taking the positive plate of polymer battery 405582 as an example, the length of the long powder side of the pole piece is 674mm, the length of the short powder side of the pole piece is 565mm, and the width is 74.8mm. mm, a series of pole piece parameters such as pole piece coating amount 41.70mg / cm2, rolling thickness 112μm, number of cut strips 2;

[0074] (2) Design parameters such as the size of the foam tape, the temperature of the foam tape and make the foam tape:

[0075] Using foam tape containing foamable microcapsules and chitosan glue, according to the requirements of battery technology and welding tab technology, the size of the empty foil reserved for welding tabs is 22mm*10mm, that is, the size of the foam tape is 22mm *10mm; According to the tape speed of 3m / min, the size of the coating oven is 8m, the maximum temperature of coating and dr...

Embodiment 2

[0085] (1) Design buried lugs:

[0086] Carry out battery design according to the size requirements of the battery model. Taking the positive plate of polymer battery 405582 as an example, the length of the long powder side of the pole piece is 674mm, the length of the short powder side of the pole piece is 565mm, and the width is 74.8mm. mm, a series of pole piece parameters such as pole piece coating amount 41.70mg / cm2, rolling thickness 112μm, number of cut strips 2;

[0087] (2) Design parameters such as the size of the foam tape, the temperature of the foam tape and make the foam tape:

[0088] Using foam tape containing foamable microcapsules and chitosan glue, according to the requirements of battery technology and welding tab technology, the size of the reserved blank area for welding tabs is designed to be 15mm*15mm, which is the size of the foam tape It is 15mm*15mm; according to the tape speed of 3m / min, the size of the coating oven is 8m, the maximum temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com