Method for preparing polaroid

A manufacturing method and polarizer technology, which is applied in the field of polarizer manufacturing, can solve problems such as screen display deformation, defects, and inability to suppress the shrinkage of polarizing films, and achieve the effects of thinner thickness and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (A) Preparation of polarizing film

[0079] A polyvinyl alcohol film with an average degree of polymerization of about 2400, a saponification degree of 99.9 mol% or more, and a thickness of 75 μm is stretched approximately 5 times in a dry uniaxial manner, and then directly immersed in pure water at 60°C while maintaining tension After 1 minute, it was immersed in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.1 / 5 / 100 at 28° C. for 60 seconds. Then, it was immersed in the aqueous solution whose weight ratio of potassium iodide / boric acid / water was 10.5 / 7.5 / 100 at 72 degreeC for 300 second. Next, after washing with pure water at 10° C. for 5 seconds, it was dried at 90° C. for 180 seconds to obtain a polarizing film in which iodine was adsorbed and aligned on polyvinyl alcohol.

[0080] (B) Preparation of adhesive

[0081] In addition, in 100 parts of water, 3 parts of fully saponified polyvinyl alcohol (Kurare Poba-ru 117H, manufacture...

Embodiment 2~5

[0089]

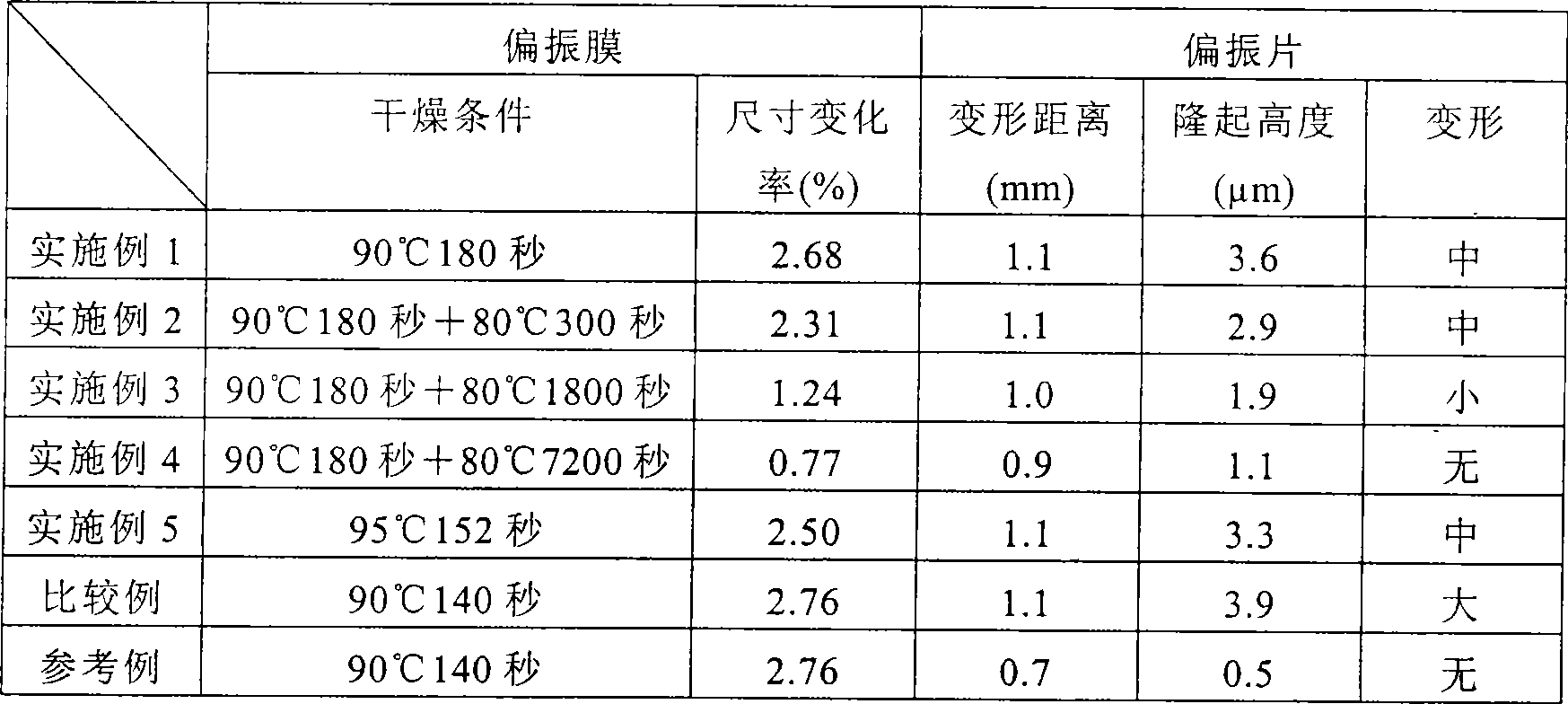

[0090] As shown in Table 1, the polarizing film was produced by changing the drying temperature and time of the polarizing film, and a polarizing plate with an adhesive layer was produced in the same manner as in Example 1.

[0091]

[0092] The polyvinyl alcohol film was subjected to dyeing treatment, boric acid treatment, and water washing, except that the drying conditions were changed to 140 seconds at 90°C, and the adsorption orientation on polyvinyl alcohol was obtained in the same manner as in (A) of Example 1. Polarizing film with iodine. On both sides of the polarizing film, pass the polyvinyl alcohol-based adhesive prepared by (B) of Example 1 and utilize nip rolls, and stick the same saponification treatment used in (C) of Example 1. A film with a thickness of 40 μm composed of triacetyl cellulose. While maintaining the tension of the bonded product at 320 N / m, it was dried at 50° C. for 5 minutes to obtain a polarizing plate.

[0093] On one side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Storage elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com