Compound voice diaphragm group

A composite sound and membrane group technology, applied in the direction of electrical components, sensors, etc., can solve the problems of poor sound quality and frequency response characteristics of speakers or receivers, unable to meet the requirements of miniaturization of electronic products, and complicated production processes, so as to achieve reduced quality, The effect of thinning thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

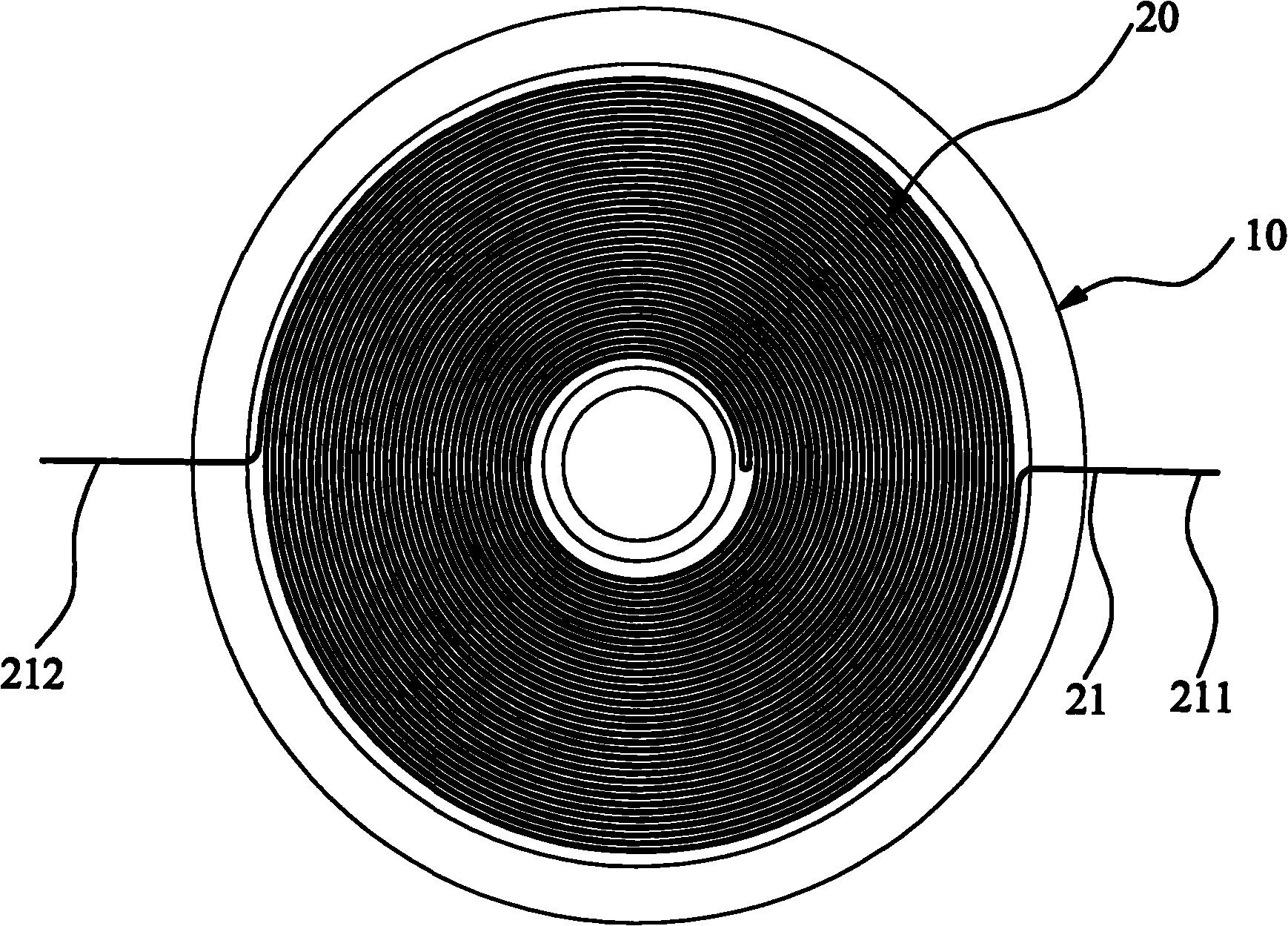

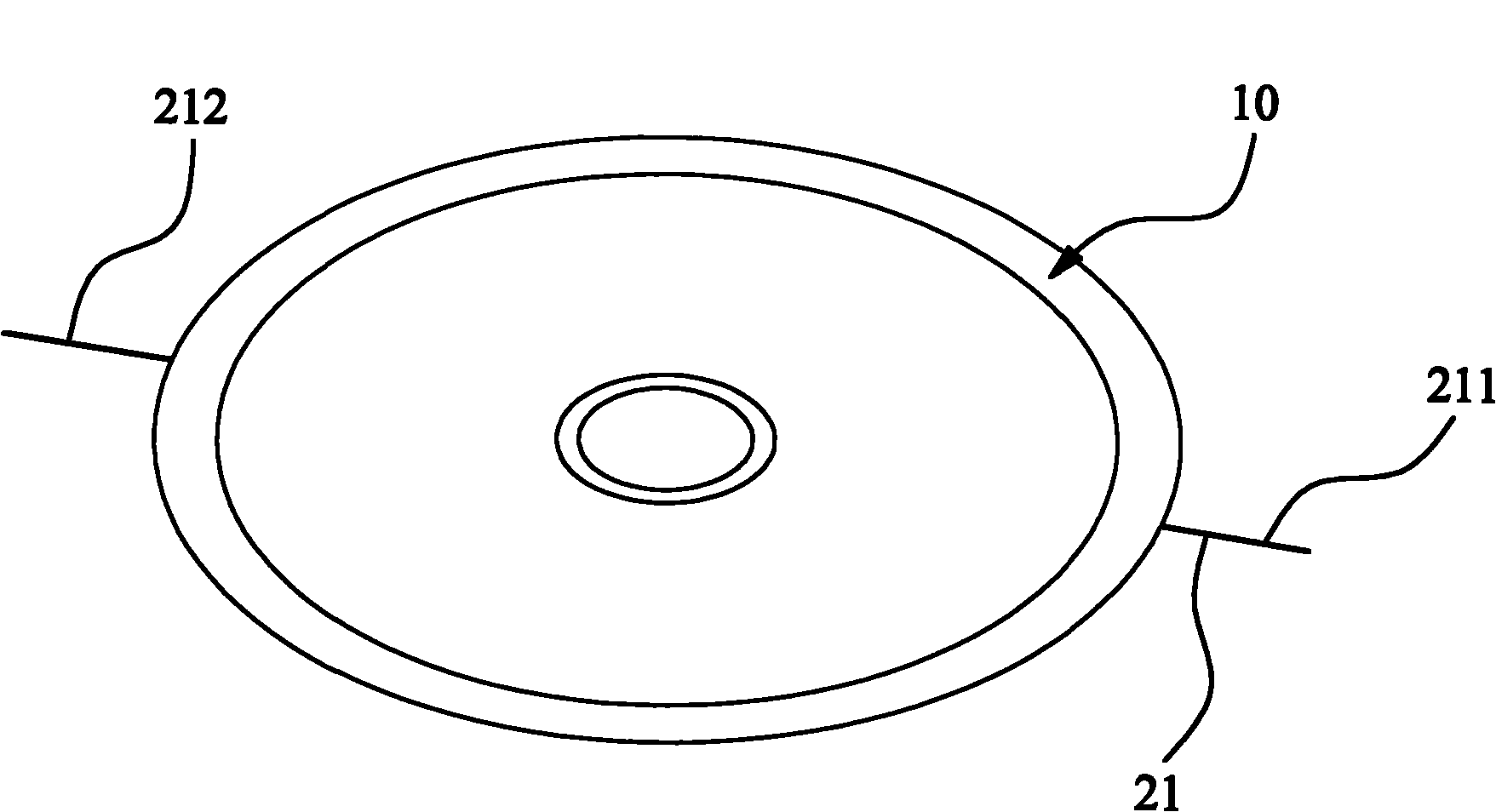

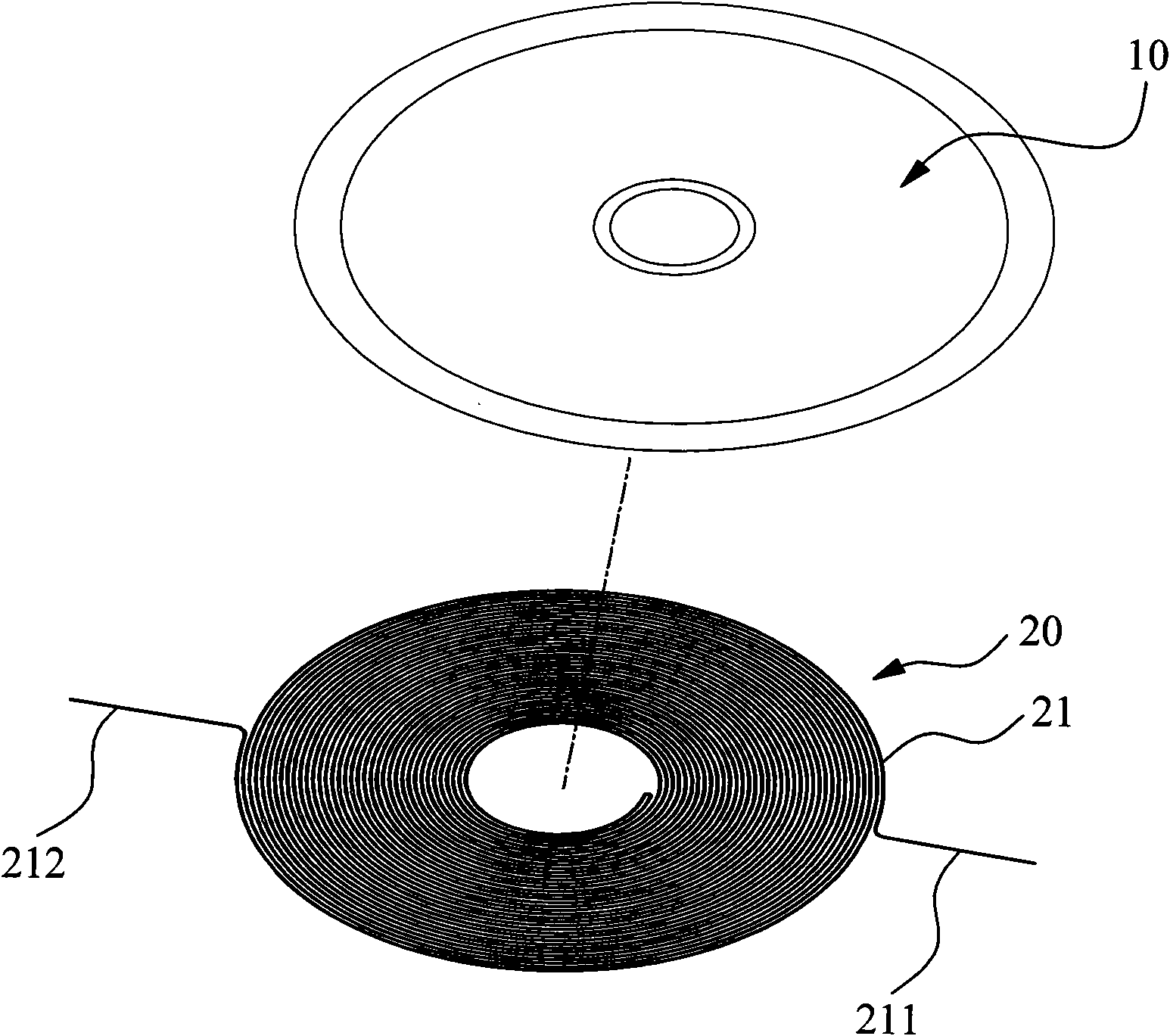

[0031] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including a sound membrane 10 and a voice coil 20 .

[0032] Among them, such as figure 2 and image 3 As shown, the sound membrane 10 is in the shape of a hollow circular plane.

[0033] like image 3 As shown, the voice coil 20 is wound by an enameled wire 21, and the enameled wire 21 is folded in half to form a double enameled wire, and the double enameled wire is tightly wound from inside to outside on the same plane to form a planar single-layer coil. The layer coil is hollow. The folded part of the enameled wire 21 is located inside the planar single-layer coil, and the input end 211 and output end 212 of the enameled wire 21 are located outside the planar single-layer coil. Of course, the double fold of the enameled wire 21 can also be located outside the planar single-layer coil, and the input end 211 and output end 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com