One-Way Graphics Materials and Methods

a one-way, graphics technology, applied in static indicating devices, instruments, transportation and packaging, etc., can solve the problems of slow process, high cost, and one-way vision films that cannot be produced in one-way, and achieve easy peeling and thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

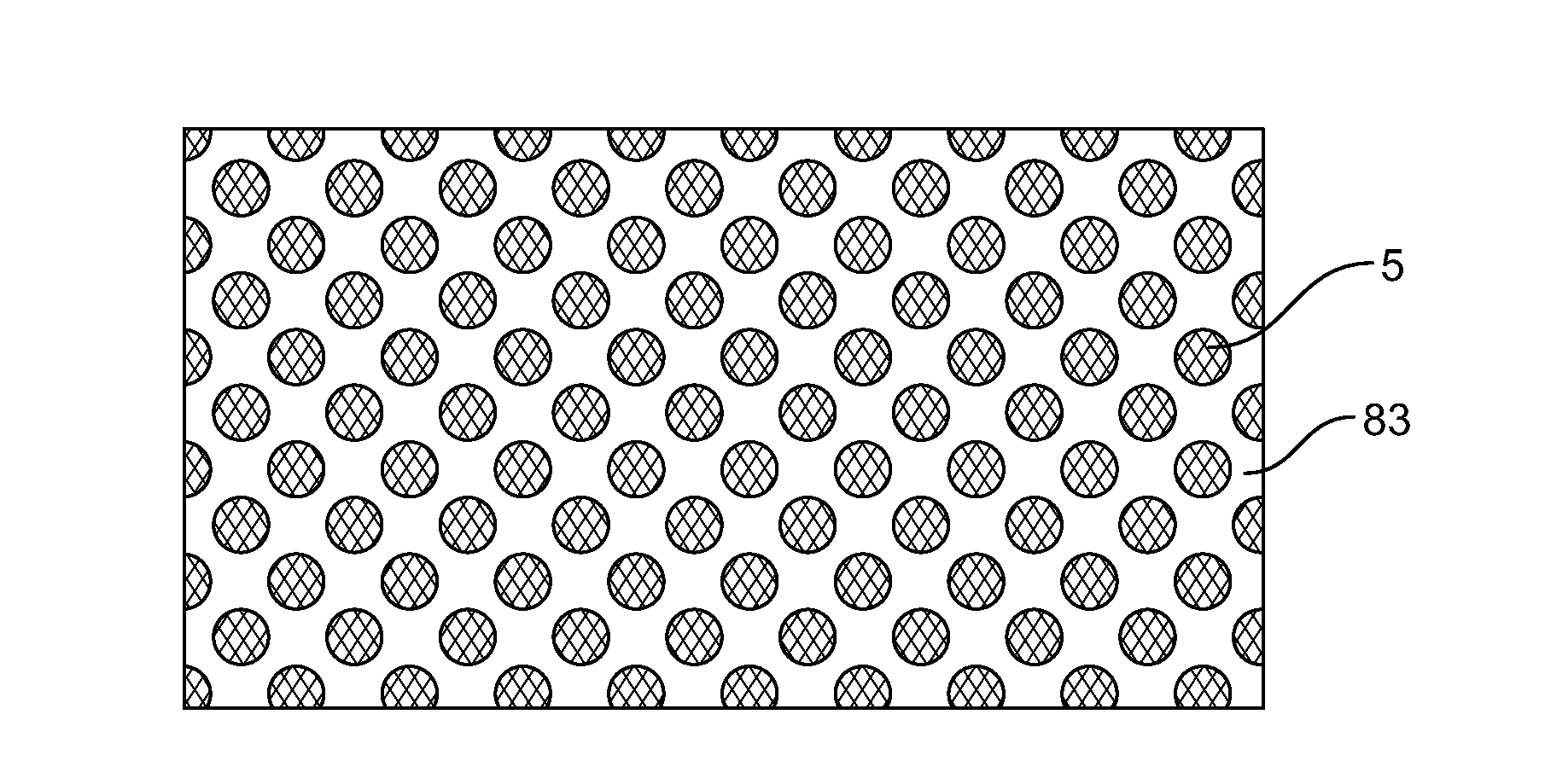

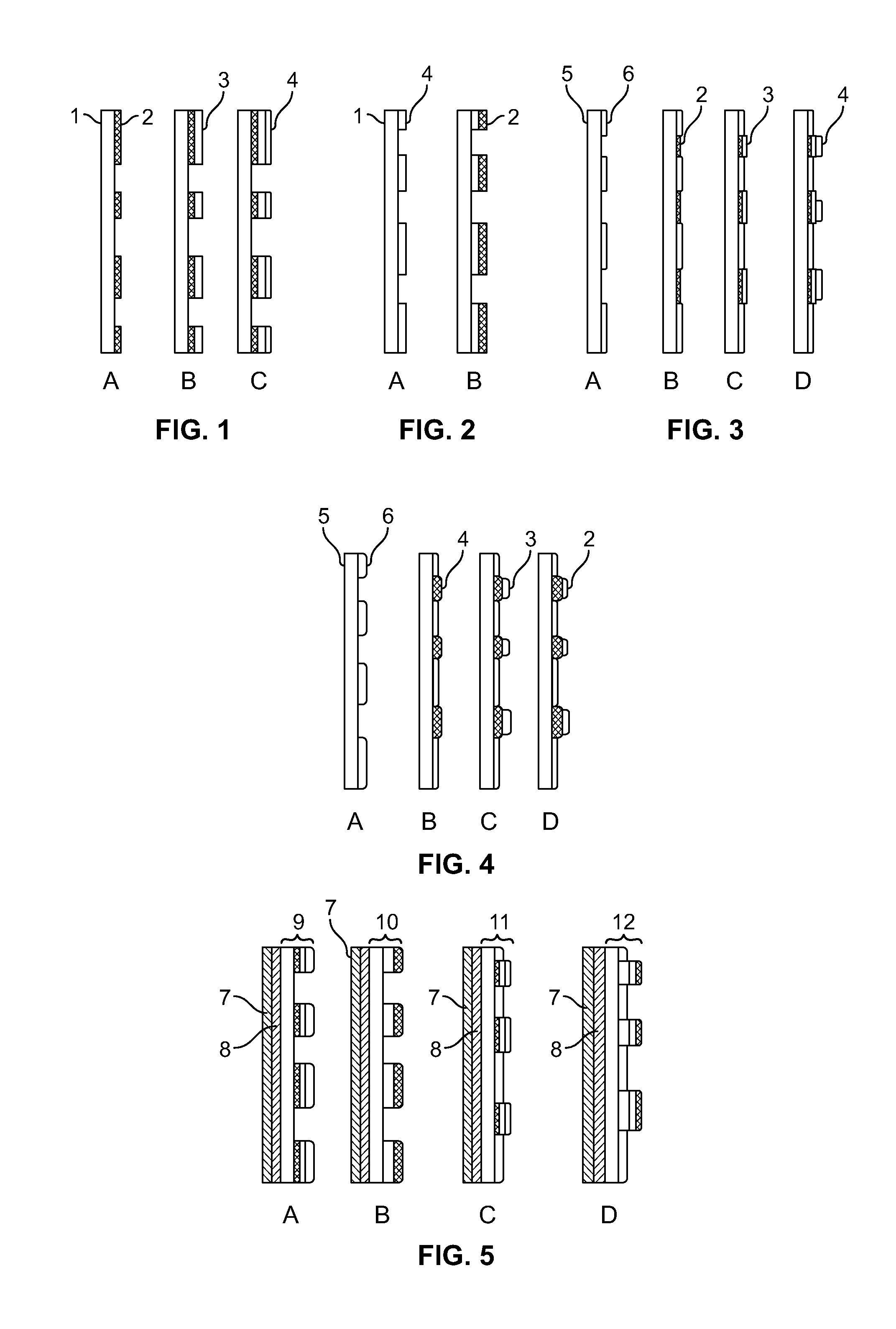

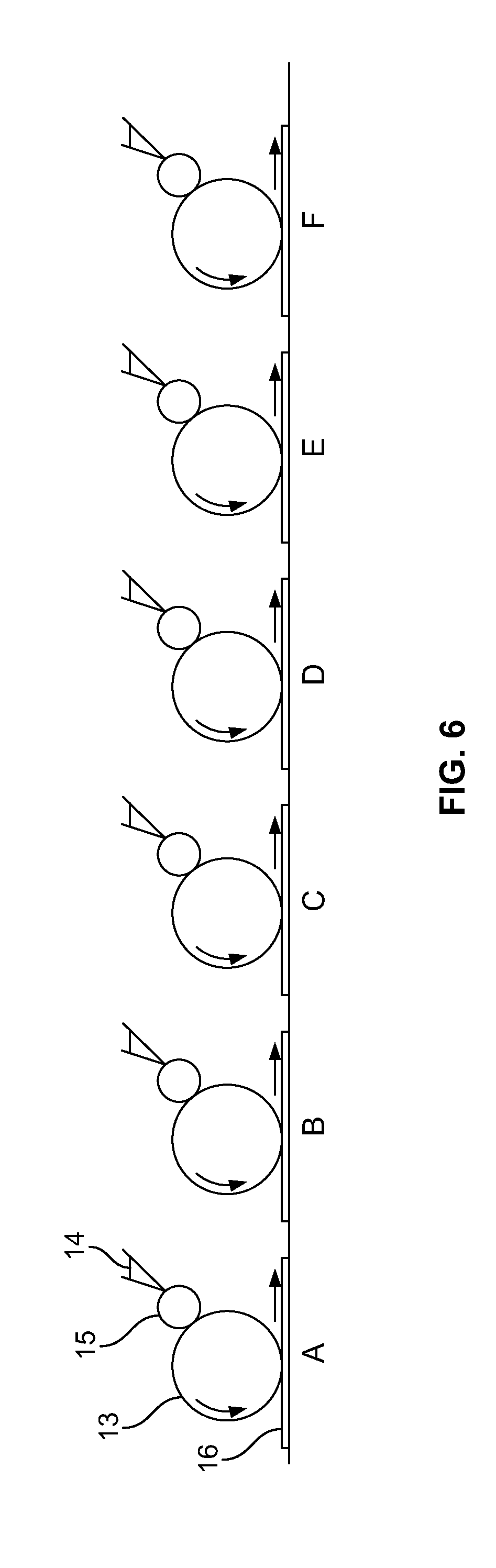

[0049]As used herein, “one-way graphic materials” refers to materials that appear essentially opaque and non-transparent from the image side, but appear substantially transparent when viewed from the non-image side under appropriate light conditions. The direction of one-way vision may change with environmental conditions, such as when night falls and lights are turned on inside a building. Images are typically placed on the light side of the one-way material. People viewing from that side will see the image. People viewing the material from the back side of the material do not see the image, but instead see the environment on the far side of the one-way graphic. Generally, one-way graphic materials are constructed using films or sheets that have multiple gaps or perforations in their non-transparent surface, thereby allowing light to permeate through the material.

[0050]“Non-printable area” or “non-bonding area” refers generally to any area of print medium which does not bond perman...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| differential conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com