Concrete engineering cavity die gasbag and manufacturing method thereof

A technology for concrete and second-stage concrete, which is used in marine engineering, earth-moving drilling, water conservancy engineering, etc., can solve the problems of irregular deformation of concrete grooves, non-reusable, soft asphalt running off, etc., to prevent cross-section interface dislocation , the section is neat, the effect of saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

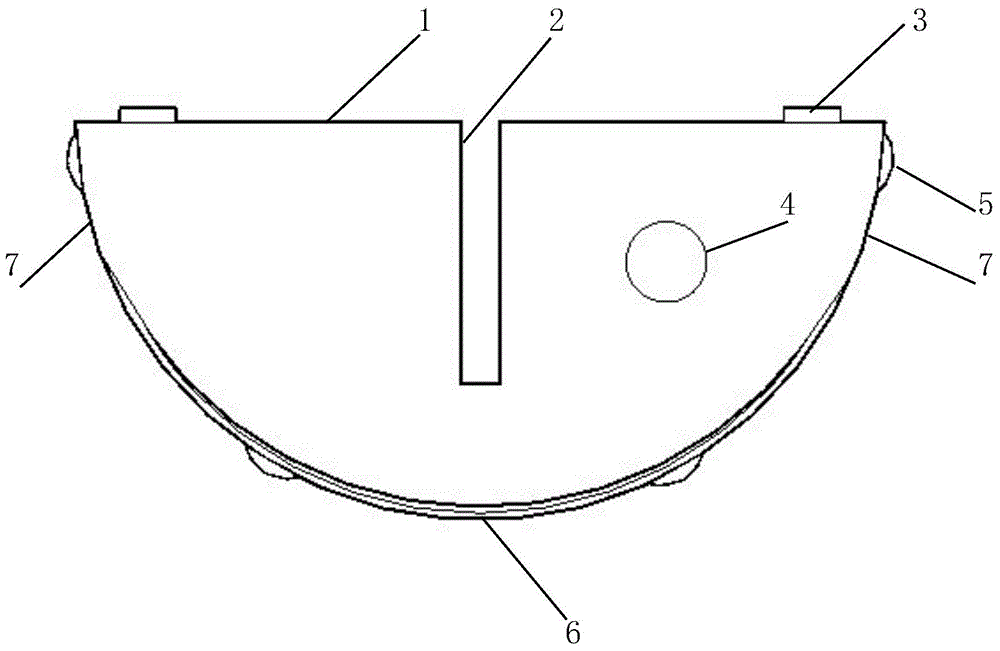

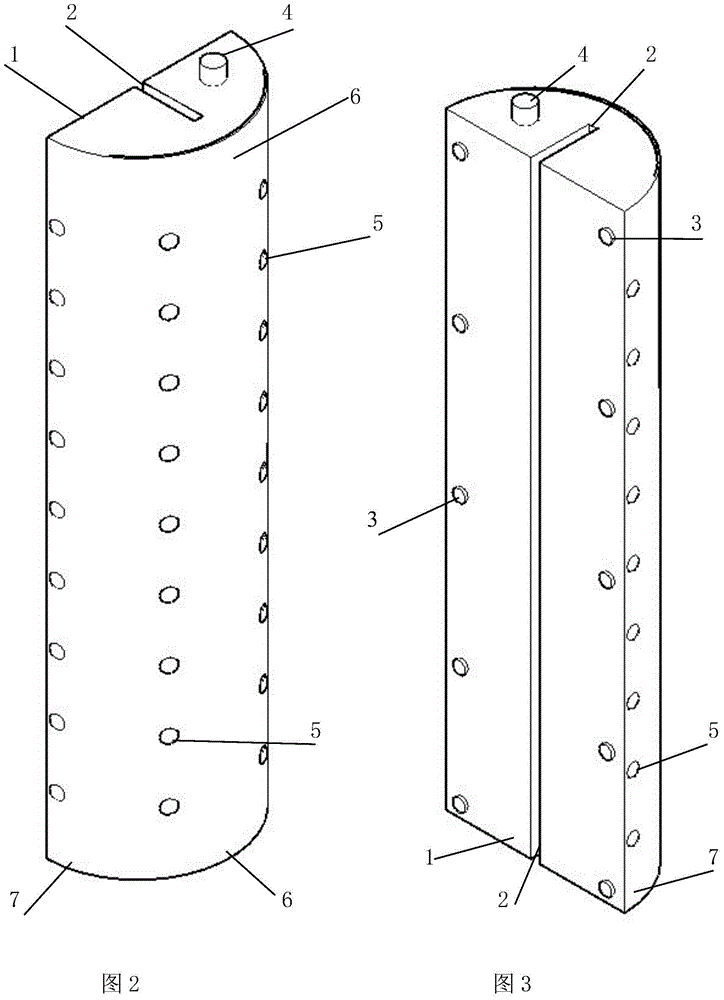

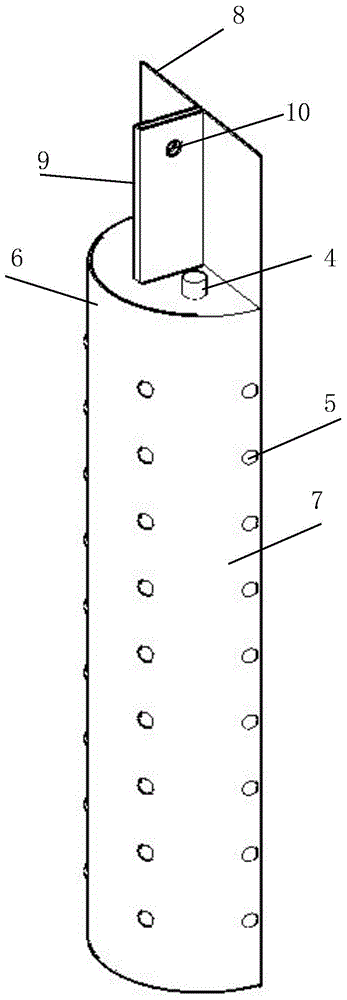

[0040] Embodiment 1, with reference to accompanying drawing: a kind of concrete engineering mold cavity mold air bag comprises hollow air bag body, and described air bag is semi-cylindrical, and the middle part of its semi-cylindrical air bag plane 1 is provided with air bag groove 2 along the length direction, The upper end of the air bag is provided with a valve 4, and the lower end is provided with a sealed bottom.

[0041] In order to facilitate airbag assembly and fixation and prevent deformation during use, the two sides of the semi-cylindrical airbag plane 1 are provided with fixed points 3 at a certain distance along the length direction, and the grooves of the airbag groove 2 and the fixed point 3 are connected to the skeleton 8. The slots 9 and the fixing holes 11 are arranged correspondingly, and are well matched to assemble the cavity mold.

[0042] In order to facilitate demoulding and achieve a certain strength, the airbag should have a certain degree of elastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com