Injection molding device for inner gears with pouring gates cut in mold, and injection molding method

A technology of injection molding and in-mold cutting, which is applied to the field of injection molding devices for internal gears, can solve the problems of slow pouring speed and uneven pouring, and achieve the effects of uniform pouring, avoiding excessive hardness and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

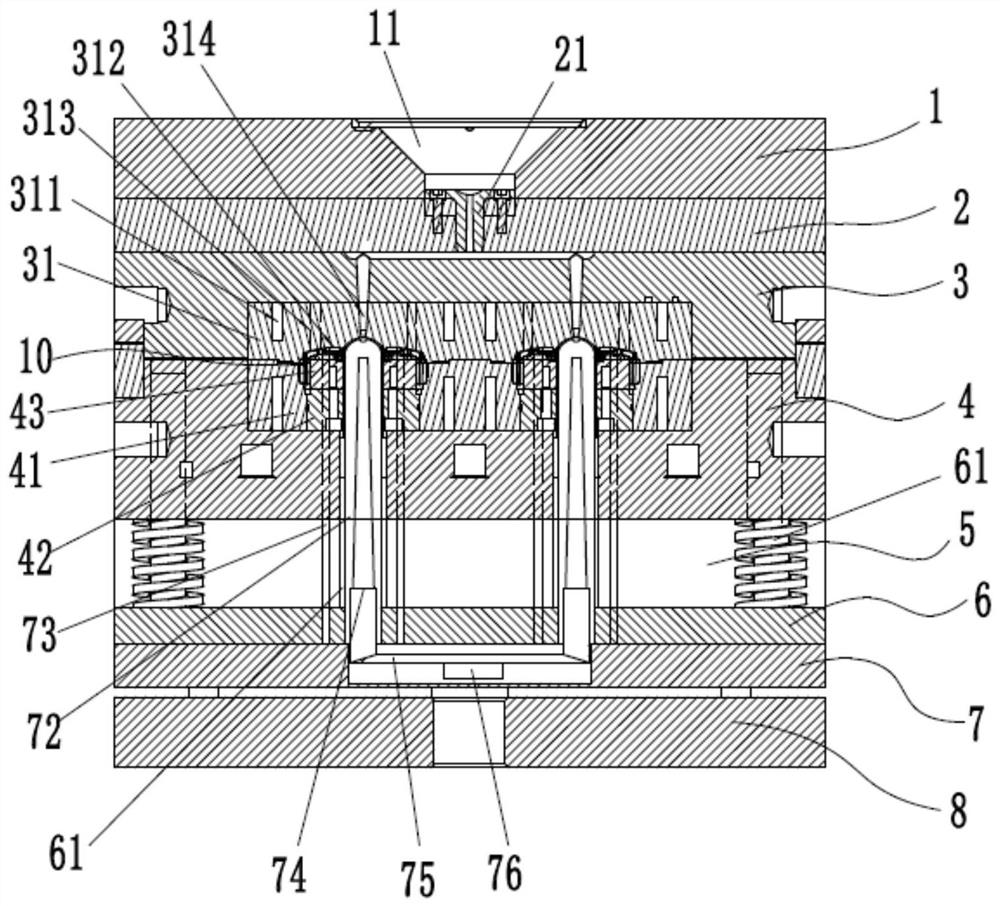

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

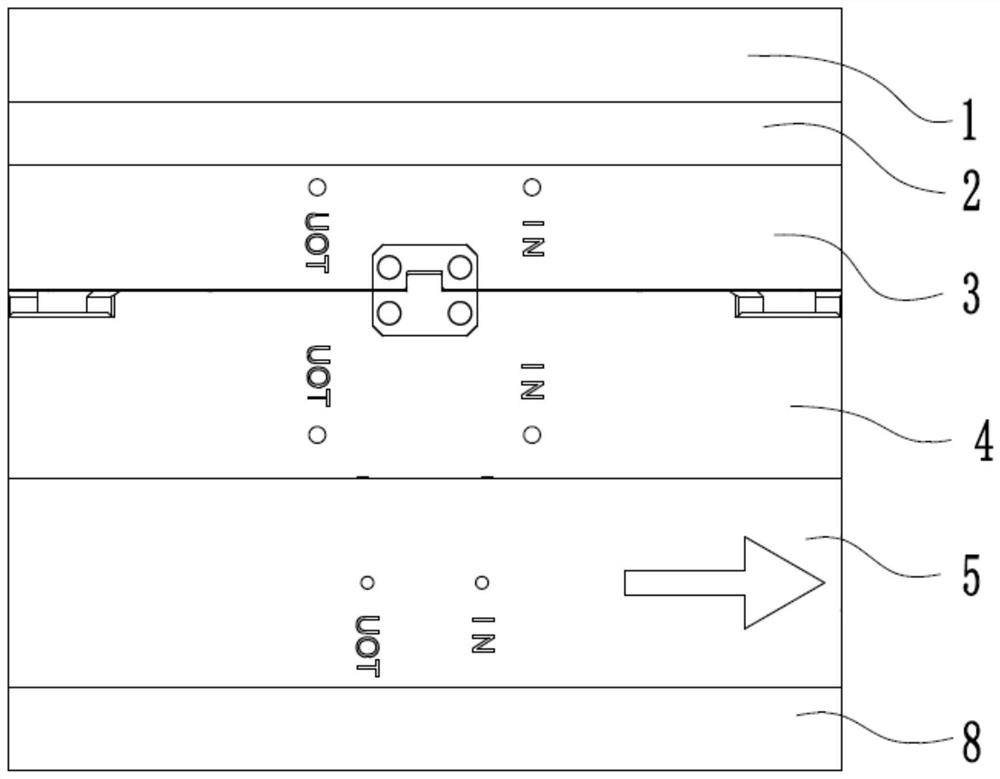

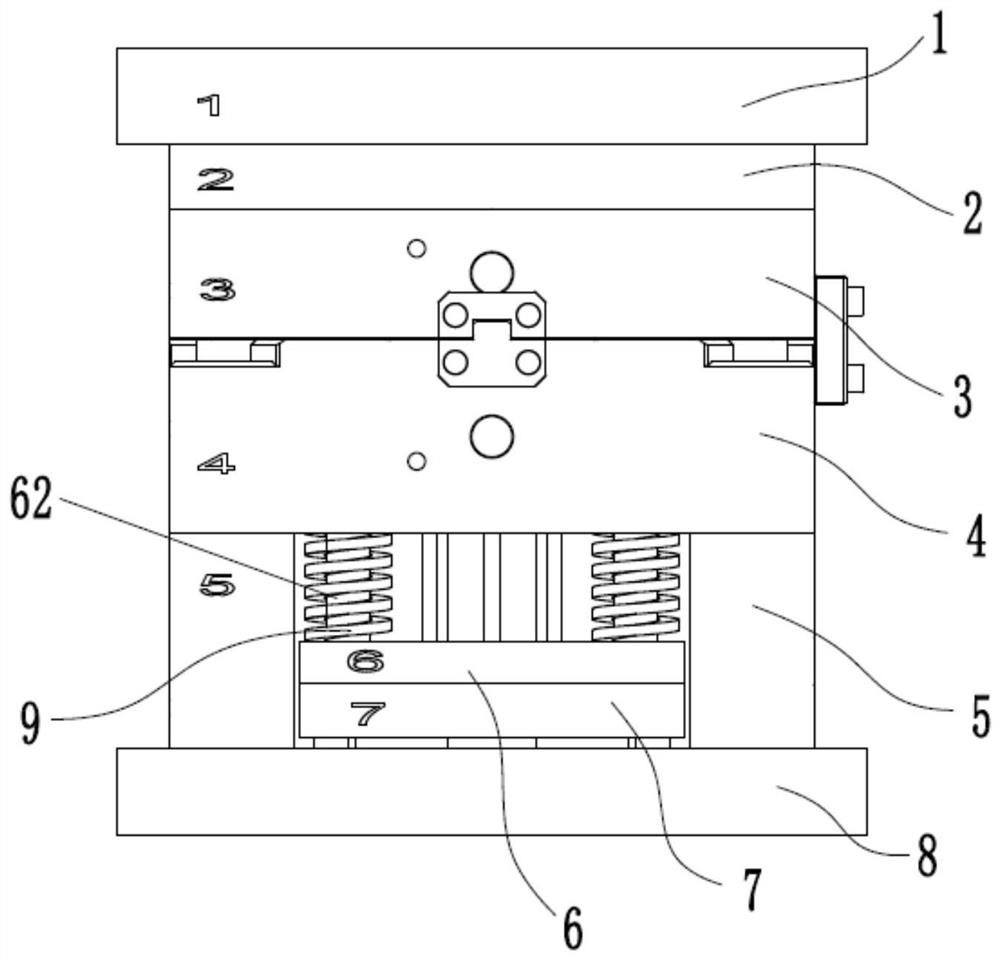

[0036] Refer below Figure 1 to Figure 5 To further explain this application, such as figure 1 The injection molding device and injection molding method of an internal gear with a shear gate in the mold shown include a base plate 8, two support plates 5 arranged on both sides of the base plate 8, and two support plates 5 stacked on the two sides of the base plate 8. Between the upper top plate 6 and the lower top plate 7, and the first template 3 and the second template 4 stacked on the top of the two support plates 5, the upper top plate 6 and the lower top plate 7 are respectively connected with the corresponding driving device, so The top of the first template 3 is fixed with a transition platen 2, the top of the transition platen 2 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com