Flexible diaphragm type ceramic material and preparation method thereof

A ceramic material, diaphragm type technology, applied in the field of ceramic materials, can solve the problems of different sizes, irregular ferrite fragments, the physical properties of flexible ferrite diaphragms and the effect of use, etc., to improve physical properties, Uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the flexible diaphragm type ceramic material of the present invention comprises the following steps:

[0033] 1) Preparation of ceramic sintered sheets printed with grid-shaped grooves, the specific process is:

[0034] 1a) Prepare ceramic slurry according to a certain ratio according to different ceramic material formulations;

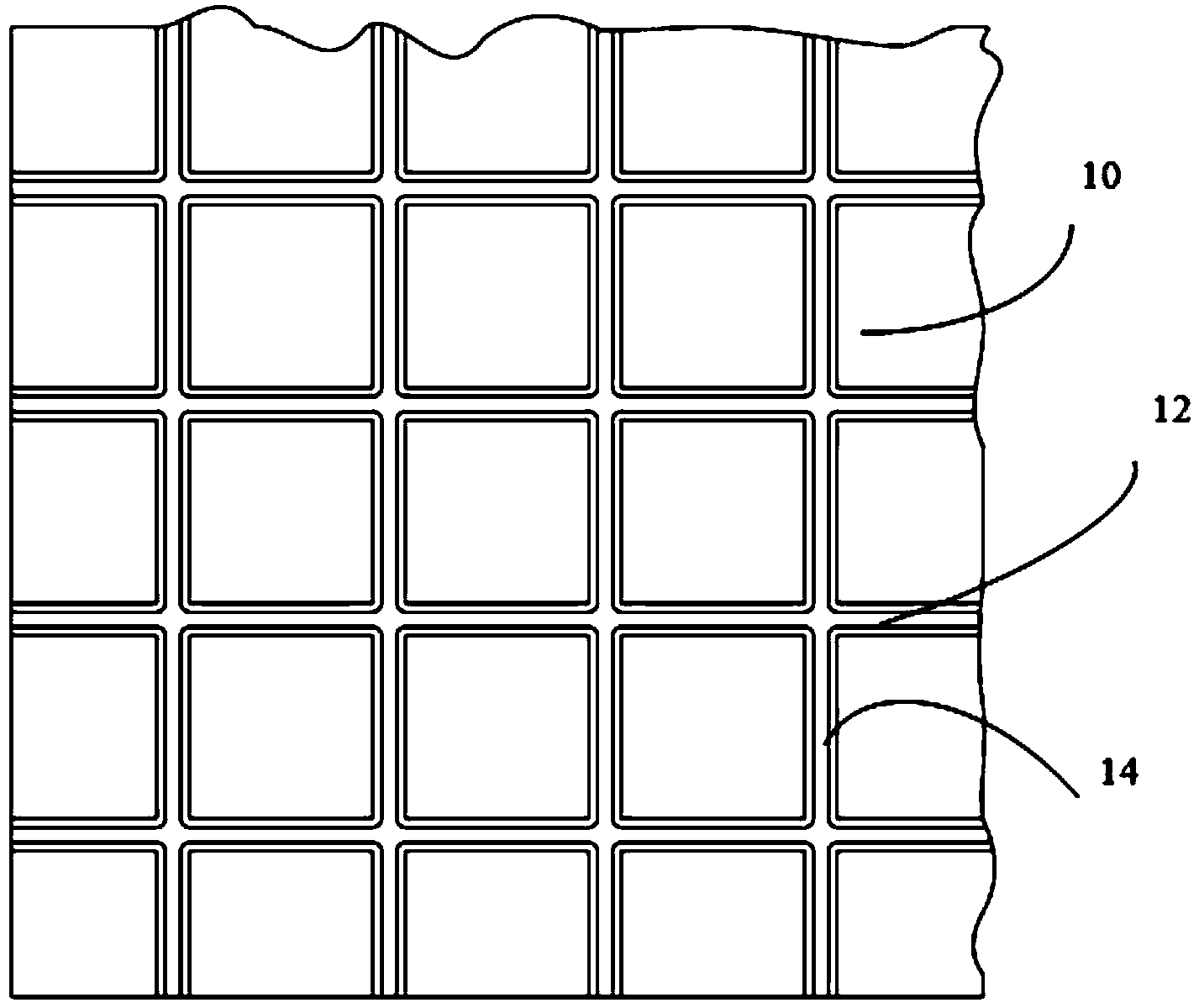

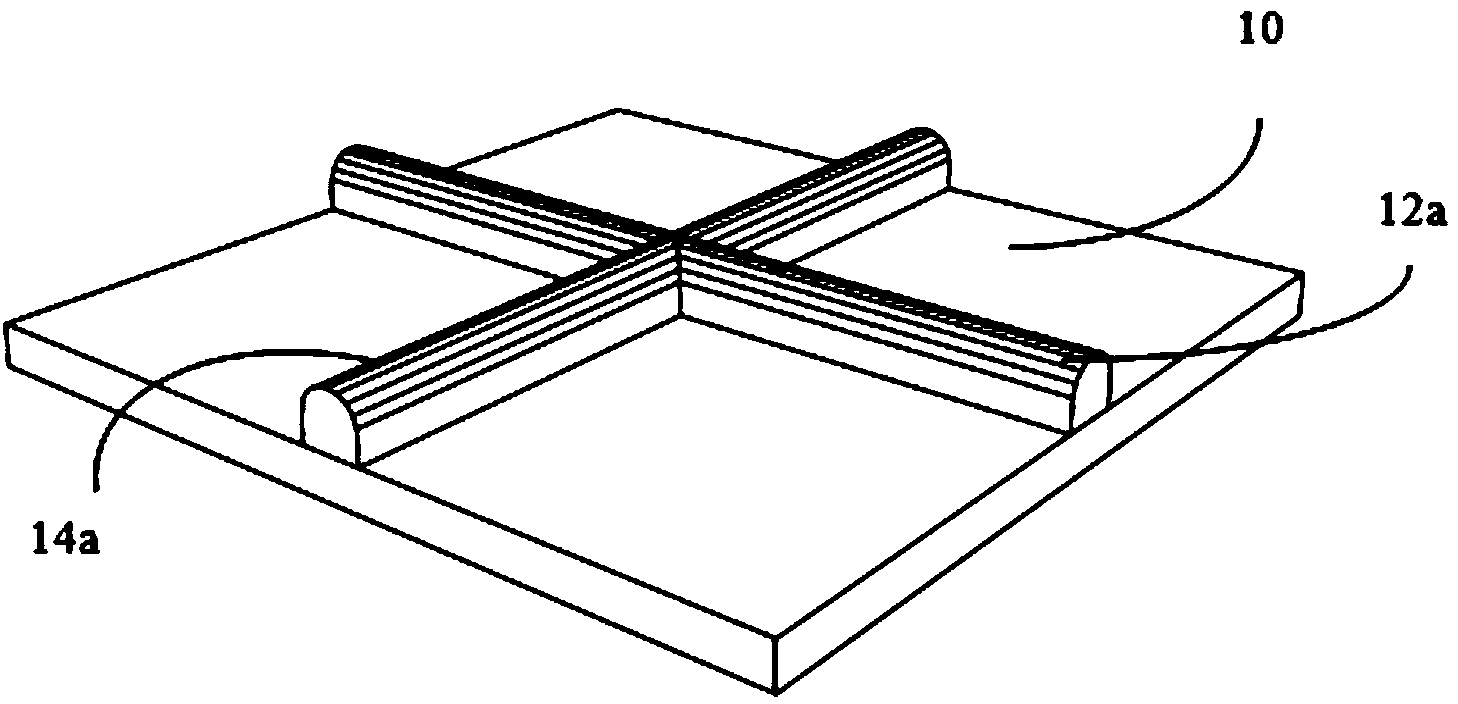

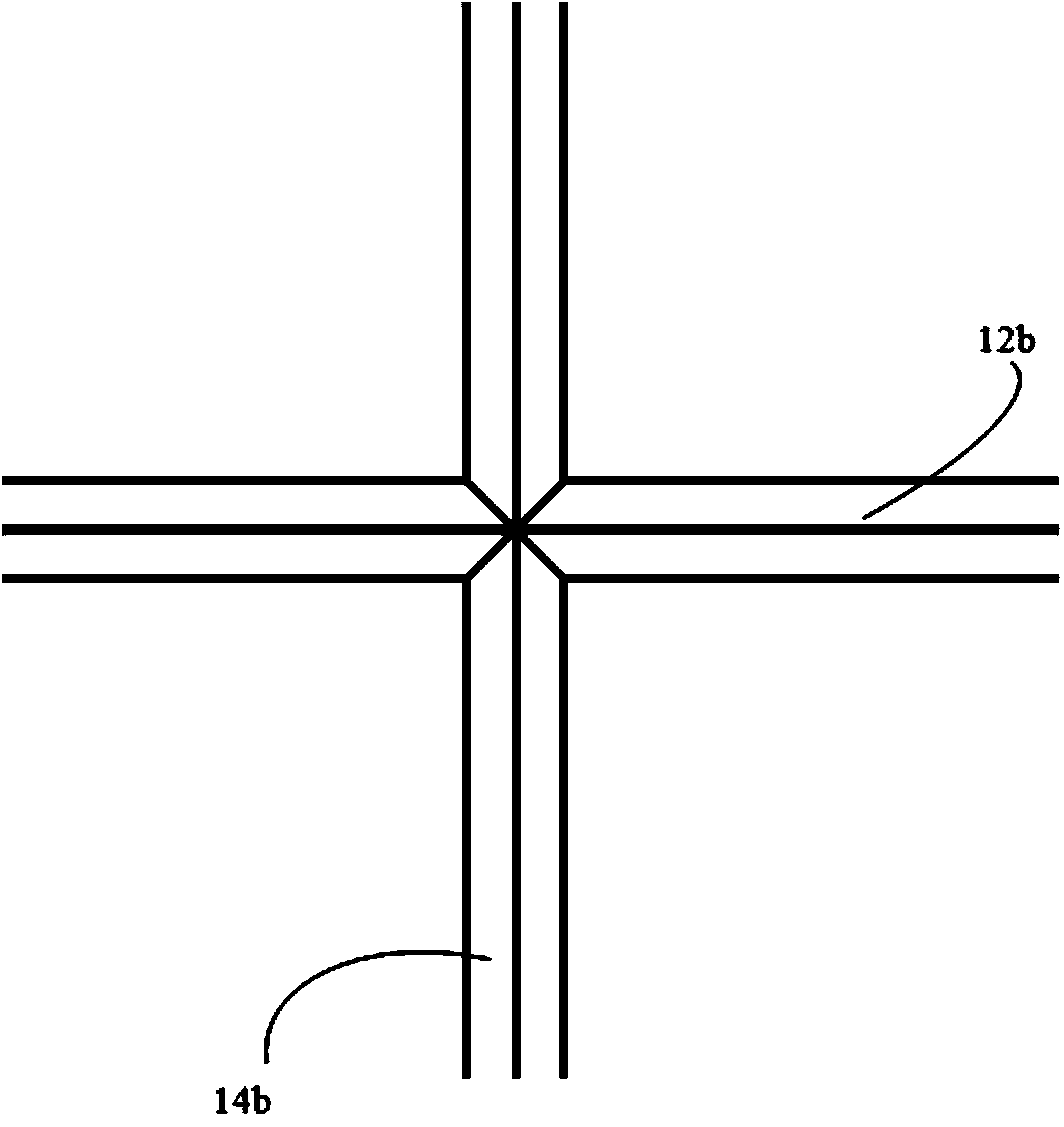

[0035] 1b) Provide a forming die 10 with grid-like projections; see figure 1 The forming mold 10 can be a knife mold or a plastic flexible film such as PET, PVC, PP, PE, PU, etc., and the grid pattern on it is a pattern formed by the intersecting of several protrusions in different directions; for example, A rectangular or square pattern formed by the intersection of transverse protrusions 12 and longitudinal protrusions 14 (that is, the transverse protrusions 12 are parallel to each other with equal spacing, and the longitudinal protrusions 14 are parallel to each other with equal spacing), wherein any two adjacent...

Embodiment 1

[0044] Utilize the preparation method of the present invention to prepare a kind of flexible sintered ferrite sheet:

[0045] Step 1: Mix and stir the ferrite powder and the binder, and prepare a slurry according to the weight ratio of 75:25;

[0046] Step 2: Prepare a PET film with grid-shaped protrusions, the intersection of its transverse protrusions and longitudinal protrusions is connected; the cross-sections of the transverse protrusions and the longitudinal protrusions are all inverted U-shaped, and the width of all protrusions Both are 0.05mm, the height is 0.1mm, and the parallel distance between two adjacent protrusions is 1mm;

[0047] Step 3: Use a coating machine to evenly coat the ferrite slurry on the PET film with grid-shaped protrusions prepared in Step 2, and the coating thickness is 0.15mm;

[0048] Step 4: Place the coated PET film and ferrite coating horizontally, with the ferrite coating on the bottom and the PET film on top, and let it dry naturally for...

Embodiment 2

[0055] Utilize the preparation method of the present invention to prepare a kind of flexible micro-alumina sintered sheet:

[0056] Step 1: Mix and stir the alumina powder and the binder, and prepare a slurry according to the weight ratio of 80:20;

[0057] Step 2: Prepare a PP film with grid-shaped protrusions, the transverse protrusions are disconnected at the intersection with the longitudinal protrusions, and the disconnection distance is 0.1 mm; the cross-sections of the transverse protrusions and the longitudinal protrusions are both Inverted V shape, the width of all protrusions is 0.1mm, the height is 0.15mm, the parallel distance between two adjacent horizontal protrusions is 1.5mm, and the parallel distance between two adjacent longitudinal protrusions is 2.0mm;

[0058] Step 3: Use a coating machine to evenly coat the alumina slurry on the PP film with grid-shaped protrusions prepared in Step 2, and the coating thickness is 0.2mm;

[0059] Step 4: Place the coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com