Auxiliary device for clamping and positioning of glass mold automatic processing

A technology for glass molds and positioning assistance, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as difficulty in leveling and alignment of end faces, reduce labor and labor intensity of workers, ensure processing concentricity, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

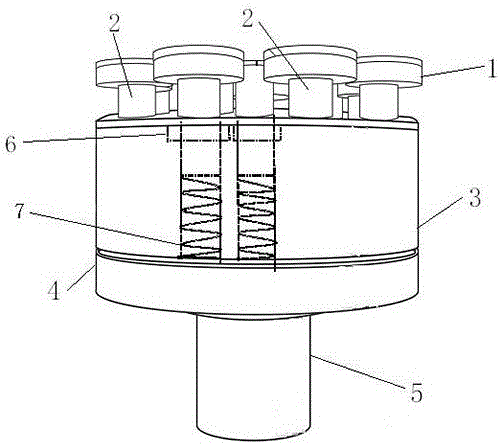

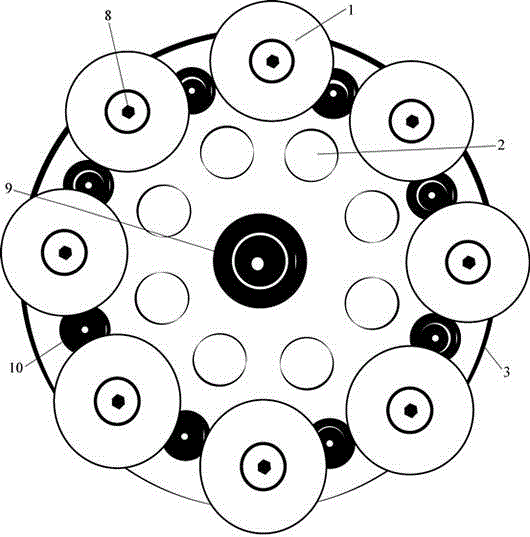

[0021] Such as figure 1 and figure 2 As shown, a glass mold automatic processing clamping and positioning auxiliary device includes a housing 3, a number of movable compression plates 1 and a number of movable compression columns 2, the housing 3 is a cylindrical structure, and the lower cover 4 passes through the lower cover. The fastening bolt 10 is fastened on the bottom of the housing 3, the spring 7 is built in the spring hole of the housing 3, one end of the spring 7 is fixed on the lower cover plate 4, the other end of the spring 7 is connected with the movable compression column 2, and the movable compression column The top of 2 passes through the top of the housing 3, and the movable compression column is provided with a limit stopper 6 inside the housing. The limit stopper 6 positions the height of the movable compression column outside the housing, and the movable compression column 2 moves Set several circles at the center of the top circle, the outer ring is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com