Horizontal pushing type safety chuck

A chuck, safe technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of affecting the depth of the winding shaft, the difficulty of oblique push design, etc., to reduce processing costs and save The effect of processing time and processing concentricity guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

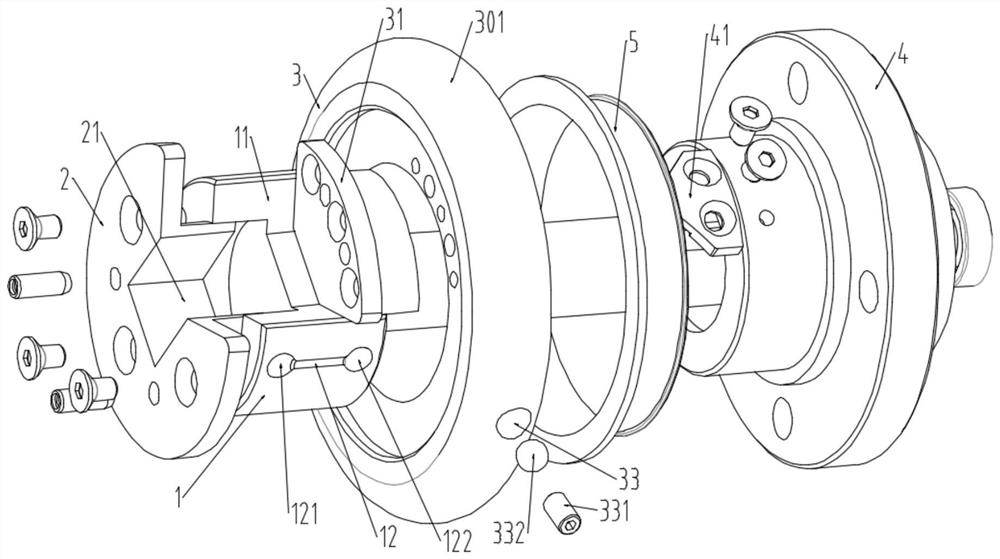

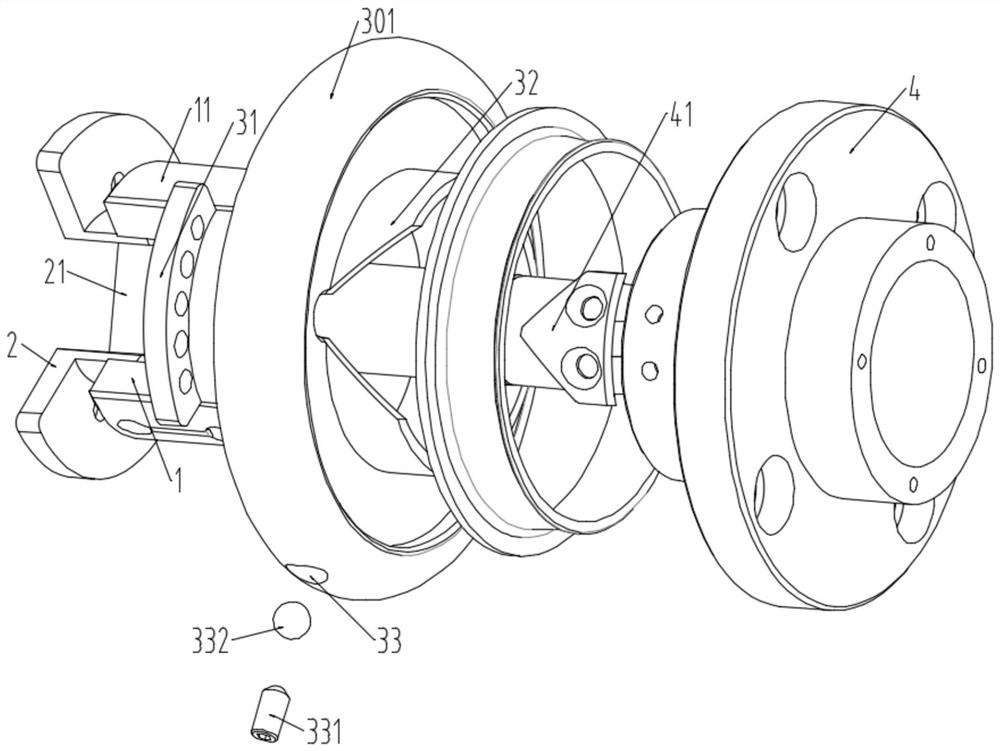

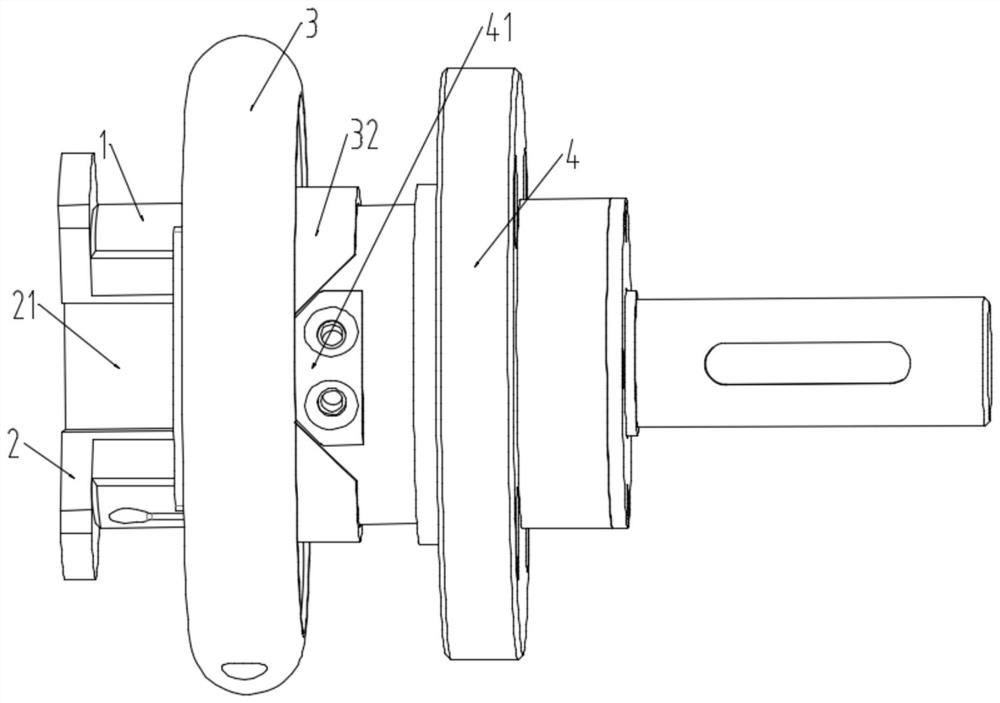

[0036] refer to Figure 1 to Figure 4 As shown, the present invention provides a flat-push safety chuck, wherein the flat-push safety chuck includes: a guide shaft 1 , a receiving assembly 2 , a push plate assembly 3 and a mounting flange 4 .

[0037] Wherein the left end of the guide shaft 1 is provided with a guide groove 11 along the axial direction. Preferably, the cross-section of the guide groove 11 is an inverted trapezoid, so as to facilitate the processing of the guide groove 11 and the clamping block 31 described below.

[0038] Wherein the receiving assembly 2 is partially embedded in the guide shaft 1, and the receiving assembly 2 is provided with a clamping opening 21 communicating with the guide groove 11 along the radial direction, so as to clamp the curling shaft. The shape of the clamping opening 21 may be square, triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com