Novel internal-external bucket cleaning brush

A technology for cleaning brushes and buckets, which is applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. The effect of fast and improving the quality of hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

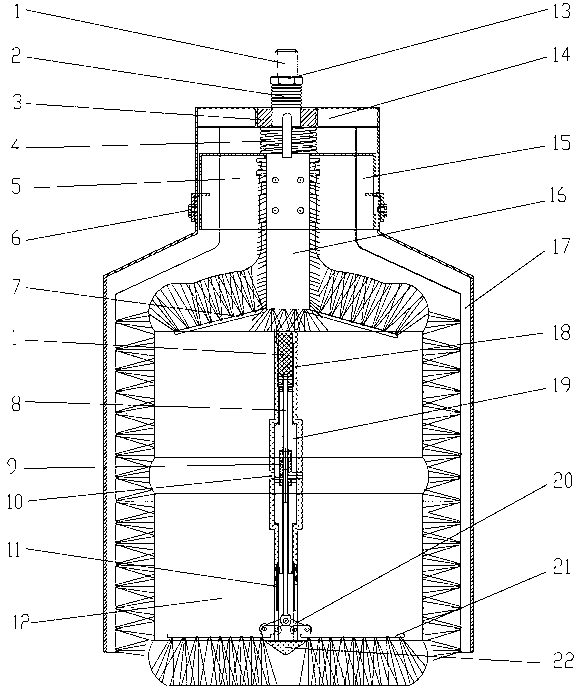

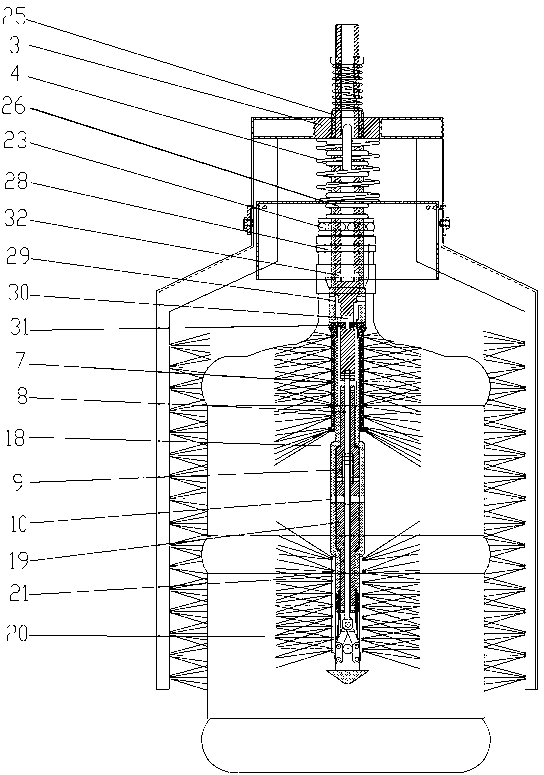

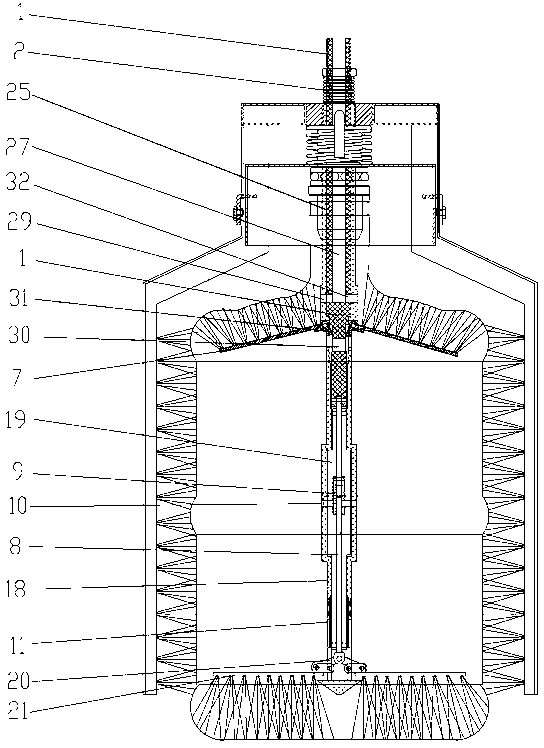

[0016] Put the inner brush rod (18) into the bucket from the mouth of the bucket (12), and the mouth of the bucket will be set on the pressure seat (28) of the mouth of the bucket, because there is a pressure bearing on the mouth of the bucket above the pressure seat (28). (23), and the thrust bearing compression spring (26) supports the barrel outer brush seat (3) fixed together with the inner brush seat sliding sleeve (25), see figure 2 , push down the inner brush shaft (1) installed in the inner brush shaft sliding sleeve (25) to slide down, and the water outlet hole (32) set under the inner brush shaft (1) goes down to It is connected with the flushing hole (29) in the barrel below the inner brush shaft sliding sleeve (25), and the cleaning water in the central water pipe (27) is sprayed into the barrel from the flushing hole (29) in the barrel, and the inner brush While the shaft (1) slides downward, the inner barrel shoulder brush guide groove (30) set at the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com