Patents

Literature

32 results about "Nylon wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

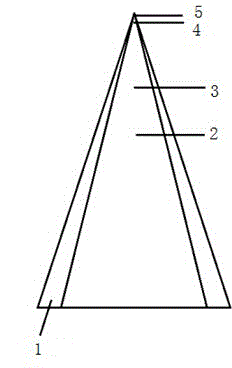

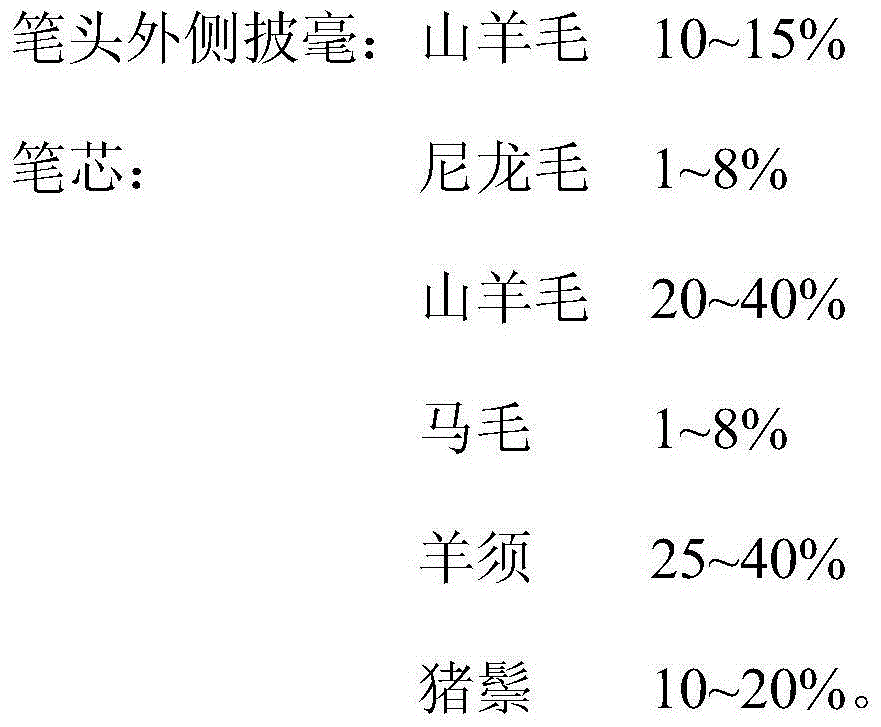

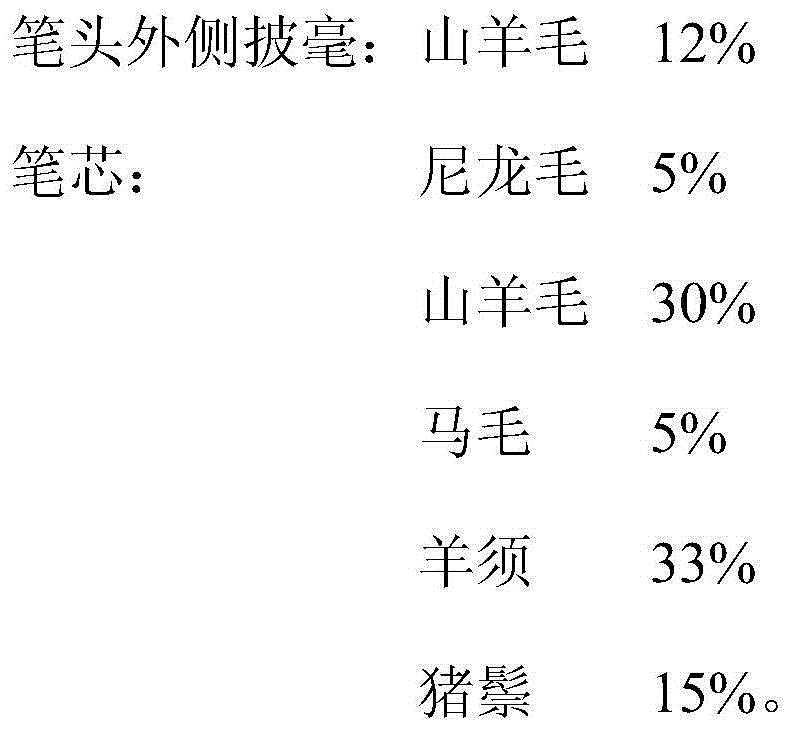

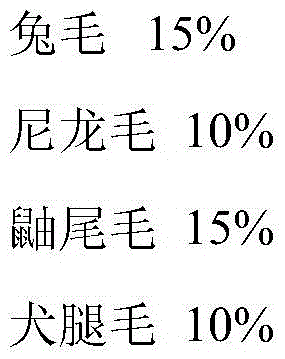

Writing brush head coupling toughness with softness, writing brush and manufacturing method thereof

The invention discloses a writing brush head coupling toughness with softness, a writing brush and a manufacturing method thereof, and belongs to the technical field of writing brush manufacturing. The writing brush head comprises, by weight: the outer layer of the writing brush head: 10 percents to 15 percents of goat hair; the center part of the writing brush head: 1 percent to 8 percents of nylon fur, 20 percents to 40 percents of goat hair, 1 percent to 8 percents of horse hair, 20 percents to 45 percents of sheep mustache and 10 percents to 20 percents of bristles. According to the writing brush head coupling toughness with softness, the writing brush and the manufacturing method thereof, the animal hair is mainly used as the raw material, a new debinding method in which the natural debinding plays a leading role and the artificial debinding plays a subsidiary role is adopted, the elastic and hard sheep mustache, horse hair and bristles are mixed matched with goat hair, so that the product is neither too hard nor too soft, couples toughness with softness, elastic without branches, durable and large in the amount of ink content; changing on the ink rhyme of the painting and calligraphy is good, the writing and drawing are free, and the addition of the small amount of the nylon fur is for strengthening the flexibility of a writing brush point.

Owner:湖州千金湖笔有限公司

Hairbrush and manufacturing process thereof

The invention discloses a hairbrush and a manufacturing process of the hairbrush. By completely optimizing the processing of nylon wool, treatment of animal wool and variety selection and match of the wool, the obtained hairbrush has high elasticity and high ink holding capacity in both writing and painting, a user can write words comfortably, the words written with the hairbrush are vigorous and forceful, stretch long and have a high artistic effect, and the hairbrush varies in hardness when used for writing. The hairbrush has high quality and good market prospects. As the nylon wool technology is improved and damage to the animal wool is reduced by improving the animal wool technology, the hairbrush is more elastic and durable and can be kept for a long period.

Owner:湖州市善琏心远笔斋股份有限公司

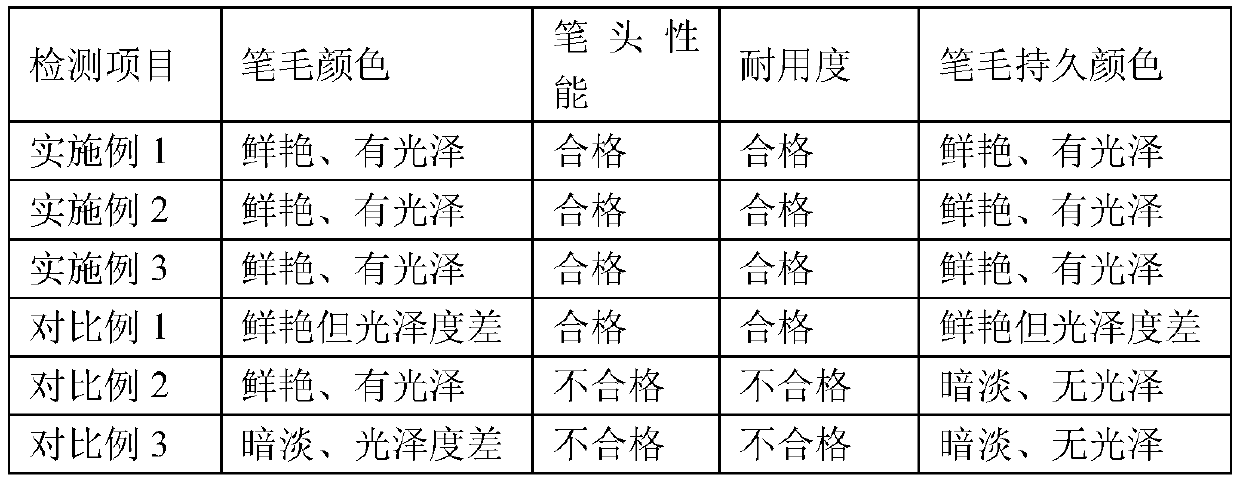

Wet transfer printing method for nylon wool electrostatic flocking cloth

InactiveCN103015240AEnhanced wash and light resistanceIdeal transfer rateFibre treatmentTransfer printing processTextile printerInorganic salts

The invention discloses a wet transfer printing method for nylon wool electrostatic flocking cloth, and belongs to the technical field of electrostatic flocking textile printing. The method comprises the steps of preparing a pretreatment solution with an inorganic salt solution and an organic acid solution, leading the nylon wool electrostatic flocking cloth to a padder filled with the pretreatment solution for padding, leading the wet nylon wool electrostatic flocking cloth and a printing film to a roll compacting device for roll compacting in a composite state, transferring patterns on the printing film to a wool surface of the nylon wool electrostatic flocking cloth, leading the wet nylon wool electrostatic flocking cloth and the printing film to a separating device from the roll compacting device, separating the printed nylon wool electrostatic flocking cloth from the printing film, rolling the printing film and leading the printing nylon wool electrostatic flocking cloth to a drying oven for drying and cooling, leading to a steam ager for aging and color fixing, washing, mellowing and drying the printing nylon wool electrostatic flocking cloth after taking out of the steam ager, and obtaining the printed nylon wool electrostatic flocking cloth. The method has the advantages that the printed patterns are clear, bright and full, the washing resistant and sunshine resistant effects are improved, energy conservation and environmental protection are reflected, and the method is simple in technology and high in production efficiency.

Owner:XINTAI FLOCKING CHANGSHU CITY

Nylon material roughing solution and roughing method using same

InactiveCN103388135AHarm reductionGood coarsening effectLiquid/solution decomposition chemical coatingElectroless nickelPolymer science

The invention discloses a nylon material roughing solution and a roughing method using same. The nylon material roughing solution comprises, by weight, 1-16% of sulfuric acid, 1-16% of hydrochloric acid, 5-15% of citric acid, 4-20% of glacial acetic acid, 1-20% of formic acid and 50-70% of water. The roughing method comprises the following steps of 1, cleaning a nylon semifinished product to remove oil and wax and carrying out secondary washing by water, 2, immersing the nylon semifinished product into the nylon material roughing solution and carrying out ultrasonic roughing at a normal temperature for 2-6min, and 3, carrying out water washing, carrying out palladium ion activation, carrying out dispergation, carrying out electroless nickel plating, and carrying out acid copper, nickel and chromium electroplating so that nylon material electroplating is finished. Through the roughing method, a nylon material has good surface roughing effects. The nylon material roughing solution reduces the damage produced by the roughing process on the environment and operators.

Owner:XIAMEN RUNNER IND CORP

Preparation method for nylon wool

InactiveCN109252238APrevent fallingImprove adsorption capacityFibre typesMonocomponent polyesters artificial filamentCellulosePolyester

The invention provides a preparation method for nylon wool. The preparation method comprises the following steps: (1) weighing, by weight, 85-95% of polyester and 5-15% of nanometer calcium carbonateand performing uniform mixing; (2) subjecting the mixture of the polyester and the nanometer calcium carbonate to drawing; and (3) performing acid treatment on threads drawn in the step (2) to obtainthe nylon wool. The invention also provides a preparation method for bristles on a cosmetic brush. According to the preparation method for the bristles on the cosmetic brush, one end of the nylon woolis immersed in a cellulose oxidizing agent, wherein oxidation time is controlled according to the length of a bristle peak; and then sharpening, washing and drying are carried out to obtain the bristles of the cosmetic brush. The nylon wool of the invention has high toughness, strong powder dipping strength and uniform powder dipping performance, and can reduce powder consumption.

Owner:ZHONGSHAN SHANGYANG PRECISION IND

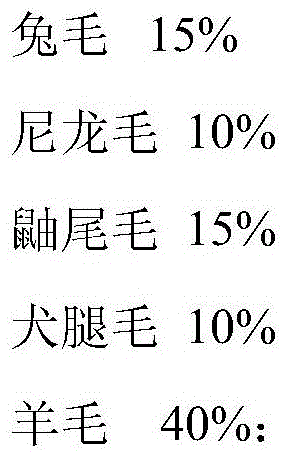

Manufacture method of writing brush

The invention belongs to the field of writing brush processing, and in particular relates to a production method of a writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) washing rabbit hair, duck hair and pig hair with soap respectively Soak in water for 50-75 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; 3) Use the treated rabbit hair, duck hair, pig hair and modified nylon hair The combing machine mixes evenly in proportion, and picks a bunch of the mixed pen core hair when making the pen core, spreads the bunch of hair on a flat plate, after grooming, and then rolls up from one end to form a conical pen tip. Put the tied nib on the pen tube and connect it with glue. Through the improved nylon hair technology, this brush is more elastic, more durable, and has a long storage time; coupled with the elasticity of animal hair itself, this brush is vigorous and powerful in use, soft and hard, and suitable for a wide range of people.

Owner:广安市广安区长乐小学校

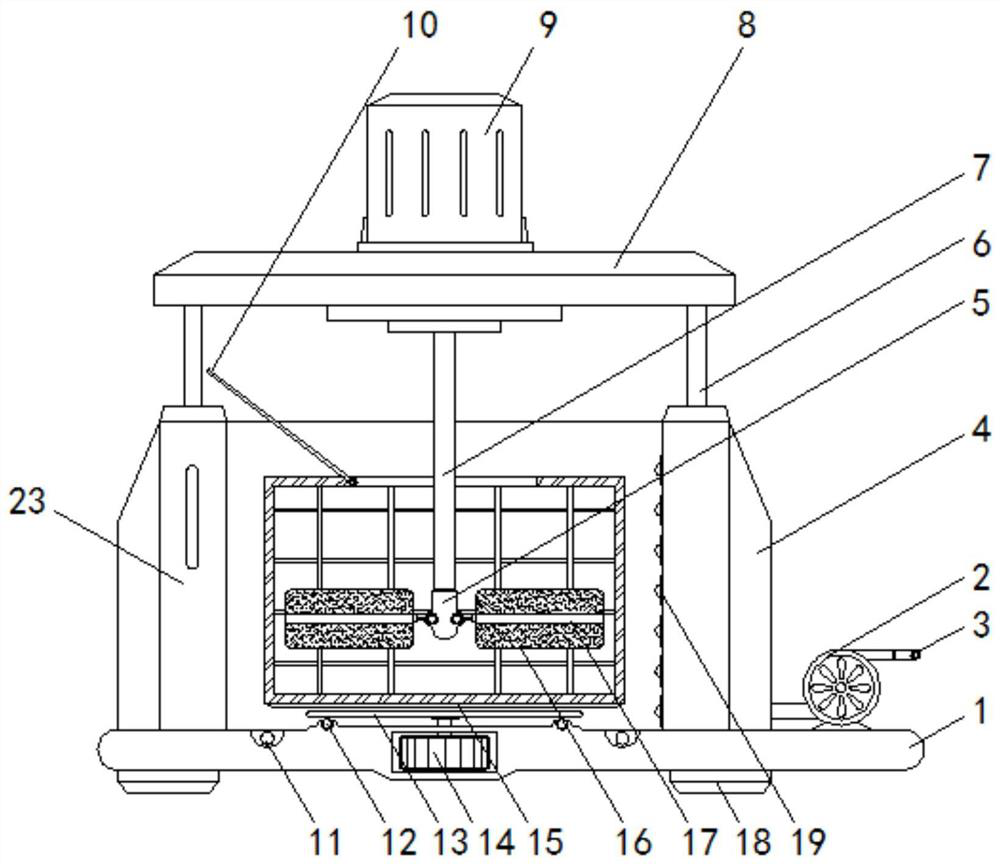

Rabbit cage hair removing device for rabbit breeding

The invention relates to the technical field of cleaning devices, and discloses a rabbit cage hair cleaning device for rabbit breeding, which comprises a cleaning base, and a cleaning fence box is fixedly mounted at the top of the cleaning base. According to the rabbit cage hair removing device for rabbit breeding, a cleaning brush is arranged to be connected with a rotating rod in a sleeving mode, the cleaning brush is a nylon brush, during cleaning, a rabbit cage box is placed into the cleaning fence box, then the cleaning brush is adjusted to extend into the rabbit cage box through a height adjusting seat under the control of a program, then a rotating motor and a cleaning motor both operate, the cleaning motor operates to drive the cleaning brush to rotate, the cleaning brush can be supported under the action of centrifugal force to uniformly clean the inner wall of the rabbit cage box, the rotating motor can drive the whole rabbit cage to slowly rotate during operation, and the rabbit cage box is comprehensively washed and cleaned through a high-pressure cleaning nozzles, so that the device is convenient for a user to use.

Owner:宁夏澳中健康产业有限公司

Hair cleaning tool

A hair cleaning tool, comprising a broom and a dustbin, the broom includes a broom handle and a broom head, the broom head is provided with broom hairs, and the broom hairs are made up of alternately arranged nylon broom hairs and rubber broom hairs; There is a hair removal port on the top of the body, and a left scraper and a right scraper connected to the box through a spring are arranged at the hair removal port. There are metal comb teeth on the left scraper and the right scraper. The top of the scraper and the right scraper are each equipped with a limit device, so that the left scraper and the right scraper are in a horizontal state without external force, and when the downward external force is applied, the left scraper and the right scraper rotate downward , open the hair removal port, insert the broom hair into the hair removal port, and scrape off the hair on the broom hair by inserting the comb teeth of the broom hair. The invention can realize cleaning and removal of hair, and has the characteristics of simplicity, convenience and sanitation.

Owner:翟志磊

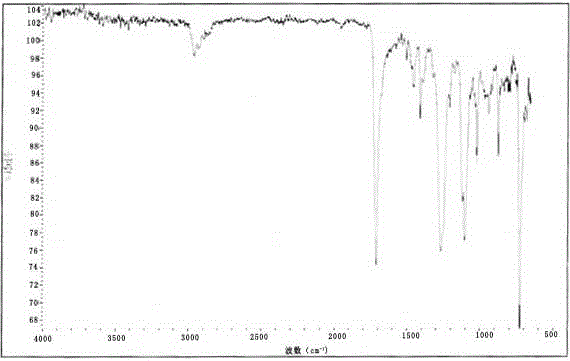

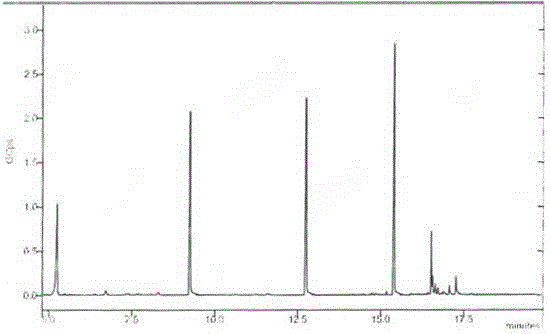

Antiaging nylon wool and preparation method thereof

ActiveCN106521948AProtect the skinEasy to cleanCosmetic preparationsToilet preparationsVitamin CMedicine

The invention discloses an antiaging nylon wool and a preparation method thereof. The antiaging nylon wool is characterized by comprising the following raw materials in percentage by weight: 0.02-0.03% of vitamin A, 0.01-0.02% of vitamin C, 0.03-0.04% of vitamin E, 0.01-0.02% of nicotinic acid, 0.6-0.7% of hydrolytic collagen, 0.4-0.6% of hydrolytic fibroin and the balance of German BASF PBT (polybutylene terephthalate) granules. The cosmetic brush prepared from the antiaging nylon wool not only has the functions of a common cosmetic brush, and but also can generate antiaging components in the use process, thereby be beneficial to protecting the skin. The antiaging nylon wool disclosed by the invention is soft and elastic, does not absorb powder, is easy to clean, and can keep the antiaging effect for a long time.

Owner:ZHONGSHAN SHANGYANG PRECISION IND

Plate-arranging type writing brush and manufacturing method thereof

The invention provides a plate-arranging type writing brush which is used for writing big characters and drawing pictures. The plate-arranging type writing brush comprises a hand plate and a plurality of brush heads, wherein the brush heads are mounted on the hand plate. Each brush head comprises an inner core and an outer core, wherein the outer core is fixedly arranged on the outer side of the inner core, the weight part ratio of the outer core and the inner core is 1:(8-10), the inner core is made of wool, bristles, horsehair and nylon wool with the weight part ratio of (3-5):(1-3):(0.5-2):(1-3), and the outer core is made of pure wool with sharp tips. The invention further provides a manufacturing method of the plate-arranging type writing brush. The brush heads of the plate-arranging type writing brush are formed by mixing the raw materials different in elasticity and hardness, and the requirements for writing big characters and drawing pictures can be better met.

Owner:HUZHOU NANXUN SHANLIAN SIDE PEN ROOM

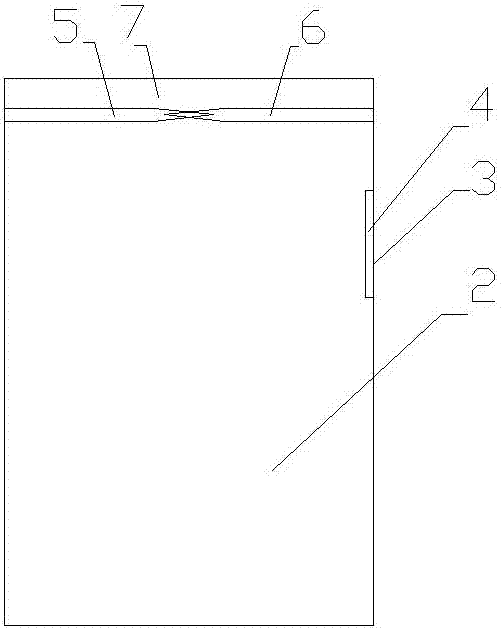

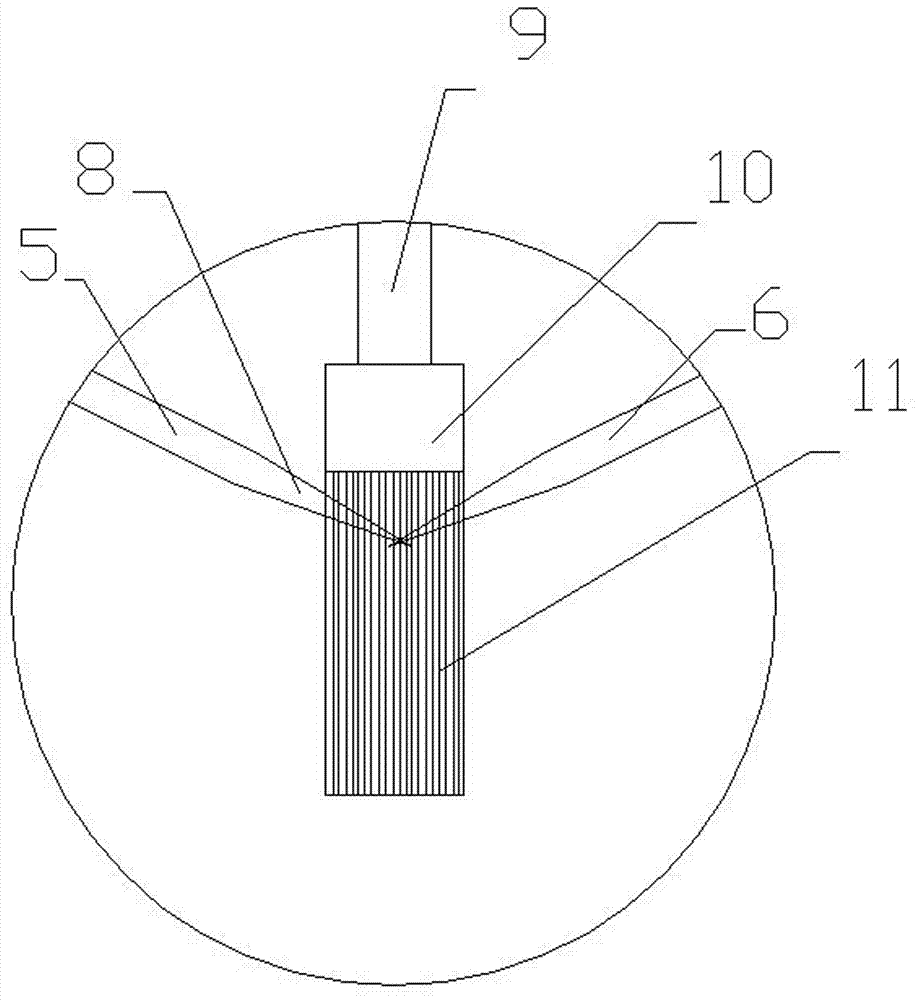

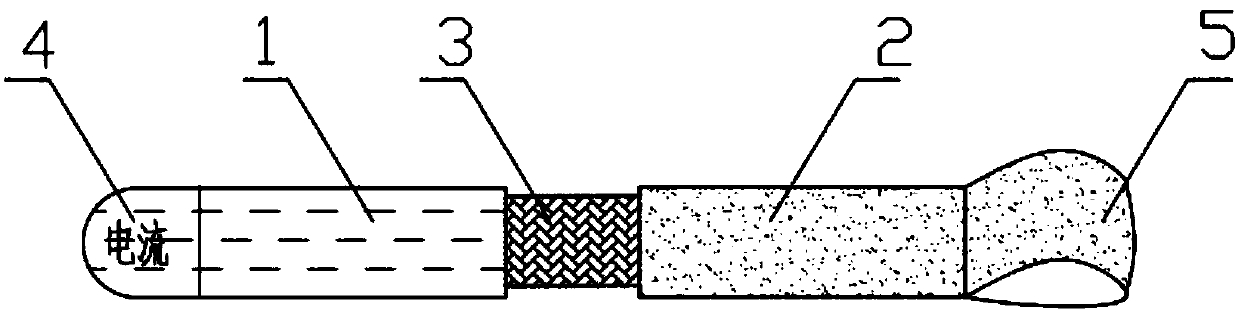

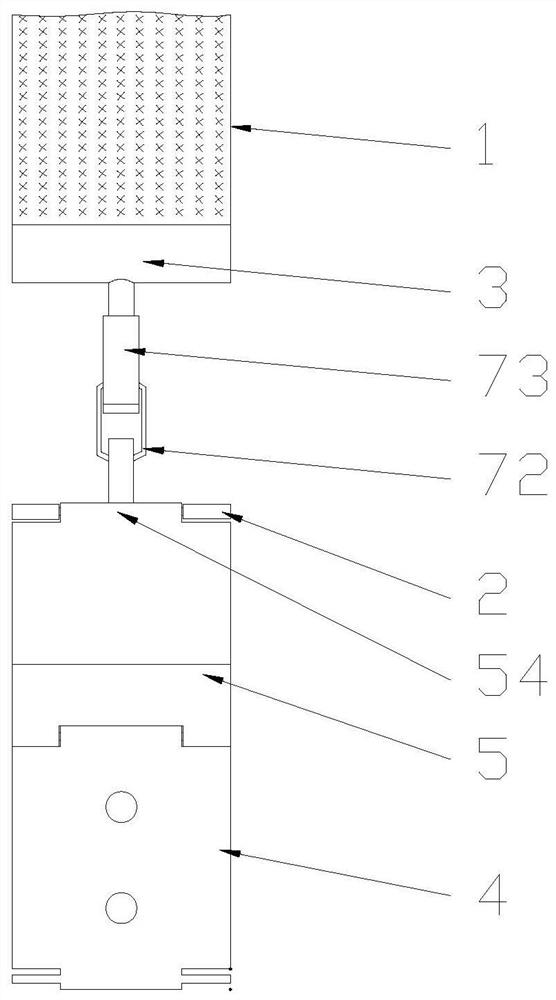

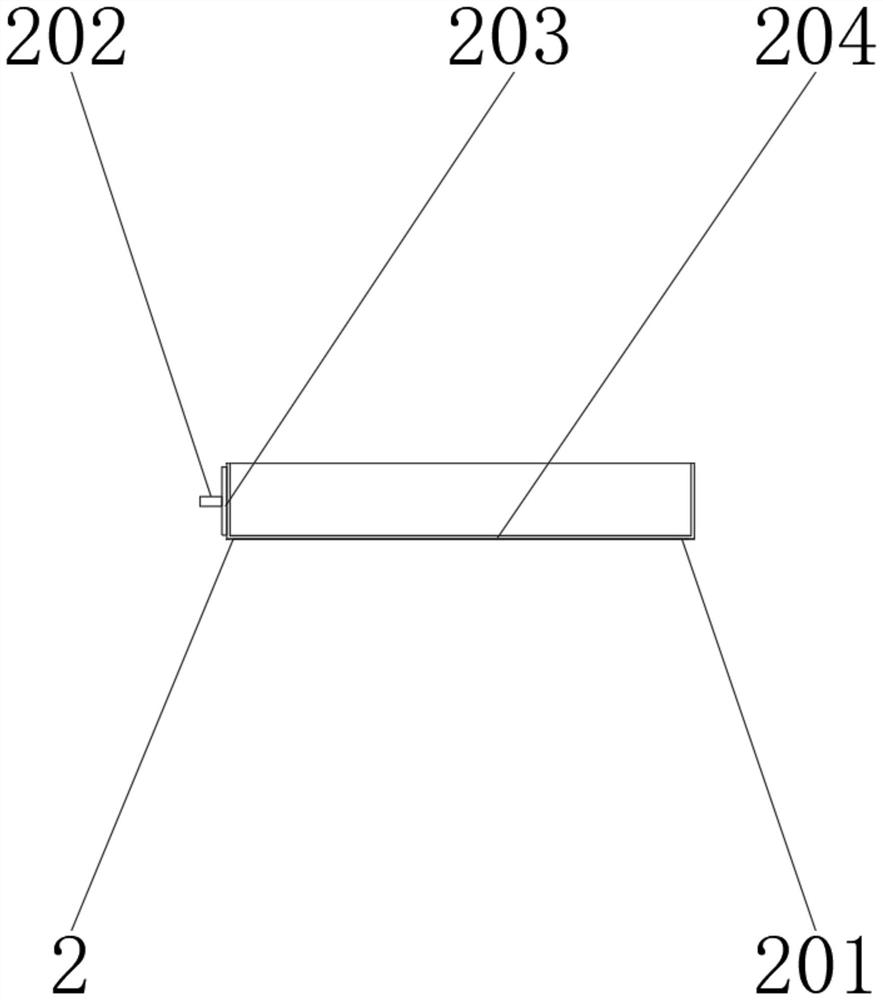

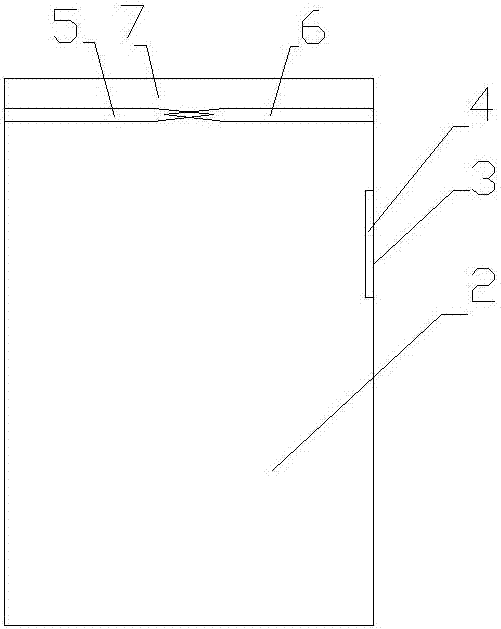

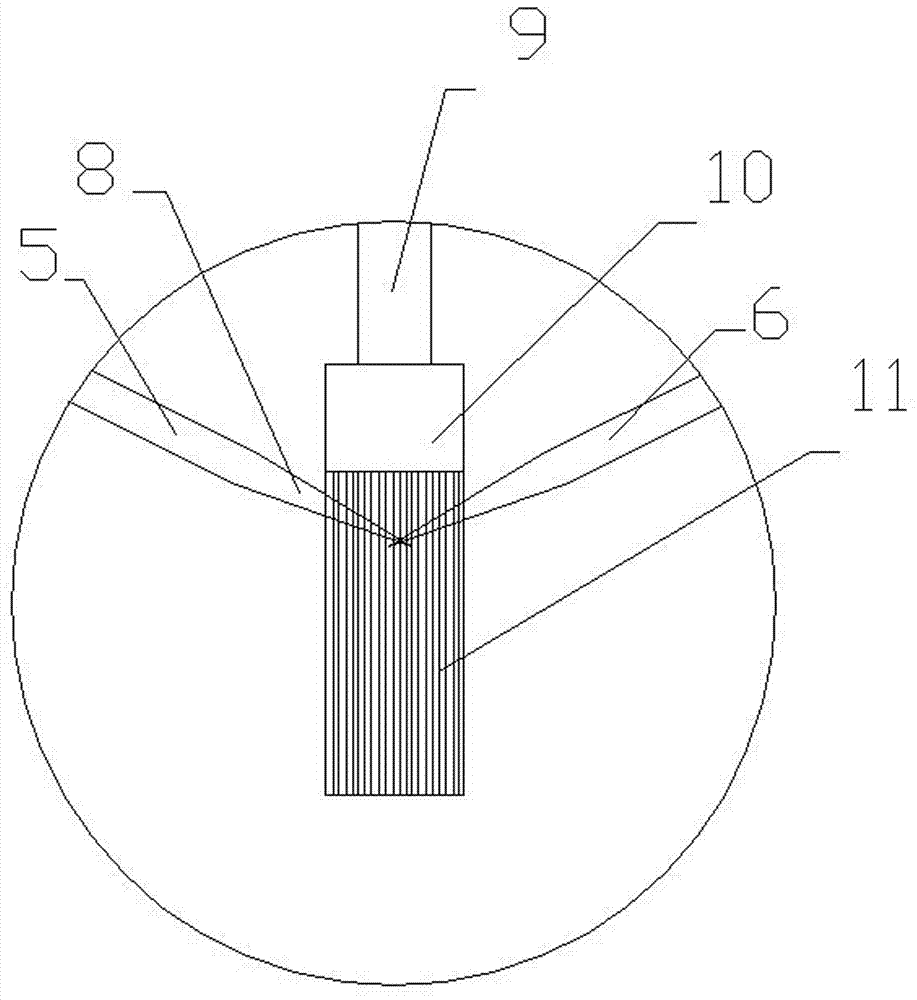

Scalable electric wire marker tie

InactiveCN107856980ASolve the technical problem that the cable tie will fallImprove securityFlexible elementsEngineeringElastic bandage

The invention relates to the professional technical field of relay protection, in particular to a retractable wire identification cable tie, including a Velcro I (1) and a Velcro II (2), and is characterized in that: the Velcro I (1) and the Velcro II (2) A section of elastic bandage (3) is arranged between them to be connected to each other, and an identification plate (4) is arranged at one end of the Velcro I (1) away from the Velcro II (2). One end of the Velcro II (2) of I (1) is provided with a cable tie loop (5), the front and back sides of the Velcro I (1) are provided with nylon hook surfaces, and the positive and negative sides of the Velcro II (2) are provided with nylon hooks. The opposite sides and the outer surface of the cable tie loop (5) are provided with nylon wool surfaces that can be sucked and engaged with the nylon hook surfaces. The invention can adapt to different wire diameters, can keep the binding of the cable ties firm and not fall under any circumstances, and also has the function of marking, which greatly improves the safety and convenience of relay protection professionals.

Owner:GUANXI POWER GRID CORP HEZHOU POWER SUPPLY BUREAU

Manufacturing method for bamboo filament brush pen

InactiveCN107718931AStable inkingInk evenlyWood treatment detailsReed/straw treatmentAcetic acidRetention time

The invention belongs to the field of writing brush processing, and in particular relates to a method for making a bamboo silk writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) separately making rabbit hair, duck hair and pig hair Soak in soapy water for 45-60 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; Soak in water for 4-5 hours, take it out and steam it for 1-2 hours, take it out and make bamboo silk; 4) Mix the treated rabbit hair, duck hair, pig hair, modified nylon hair and bamboo silk in proportion with a carding machine , Pick a bundle of mixed refill hair when making a refill, spread this bundle of hair on a flat plate, after grooming, and then roll it up from one end to make a conical pen tip, and put the tied pen tip into To the pen barrel, add glue to connect. The brush made by the invention is elastic, more durable and has a long storage time.

Owner:广安市广安区长乐小学校

Production process for peacock writing brush

The invention discloses a production process for a peacock writing brush. The production process comprises the following steps of selecting materials; pretreating; producing a brush head; installing the brush head; and modeling. According to the production process, before peacock feathers are heated to remove grease, the peacock feathers are cladded with glycerol first, so that the influence of heating and repeated rubbing on a colorizing structure of the peacock feathers can be effectively reduced; and the damage of long-term use to the colorizing structure of the peacock feathers can be remarkably reduced by subsequently adopting a mode of soaking the peacock feathers with a specific treatment solution, so that the beautiful appearance is favorably maintained and the durability of the writing brush is improved. In the brush hairs of the peacock feathers disclosed by the invention, the weight percentages of wool, nylon wool and the peacock feathers are 35 to 45 percent, 15 to 25 percent and the balance. Various raw materials in the brush head are reasonably matched; and the peacock feathers have good wrapping performance, are easy to write and free of splitting and gathering, andinitiate a new writing brush material.

Owner:HUZHOU SHANLIAN YONGHEFENG PEN HOUSE

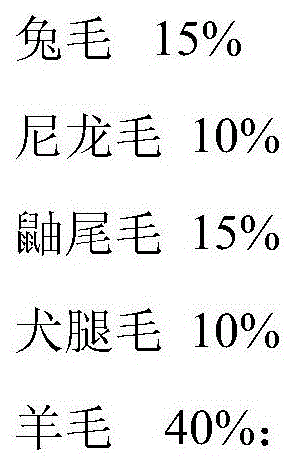

Spinning method for middle and long acrylic fiber Bosilun polyester nylon wool and purl 16N blended yarn

The invention relates to a spinning method for middle and long acrylic fiber Bosilun polyester nylon wool and purl 16N blended yarn, and belongs to the technical field of textile production. The blended yarn is composed of middle and long acrylic fiber, Bosilun polyester fiber, nylon fiber, wool fiber and purl fiber. The spun yarn is obtained through the steps of raw material processing, manual mixing, blowing, cotton carding, drawing, roving and spinning, and a made fabric is soft in touch, fluffy, bright in color, high in elasticity and high in hair sense, has slight moisture absorption andsweat releasing effects, and has good affinity with skin.

Owner:浙江华利锦纺织股份有限公司

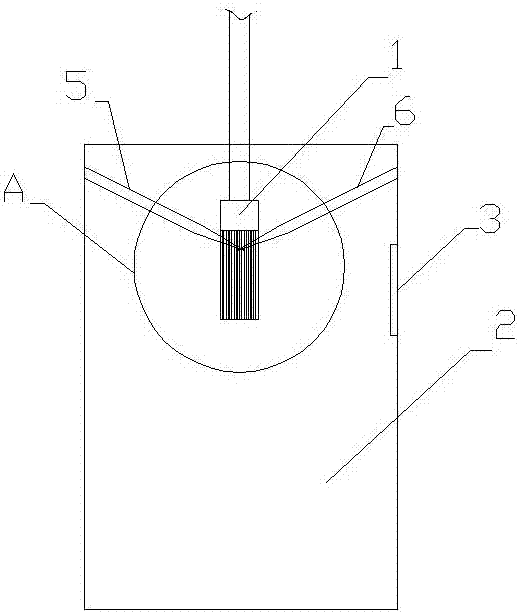

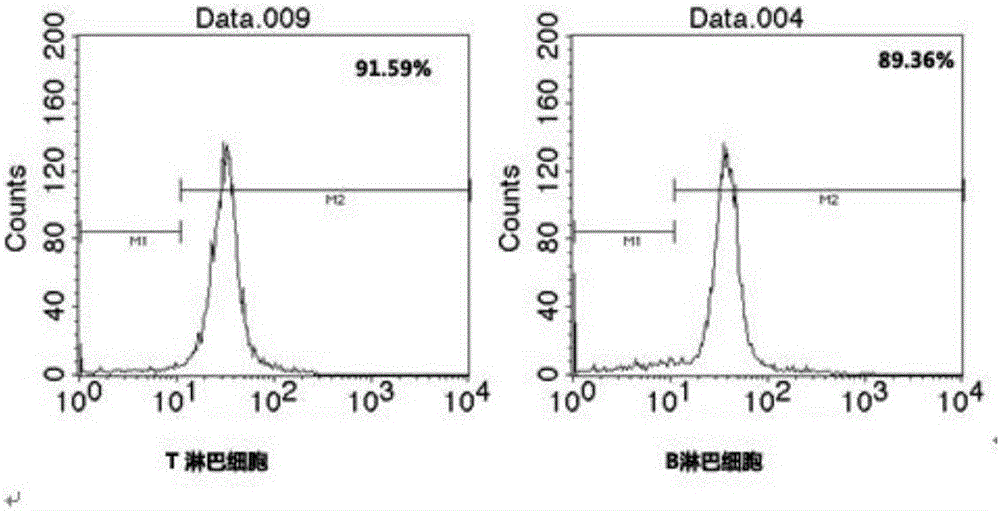

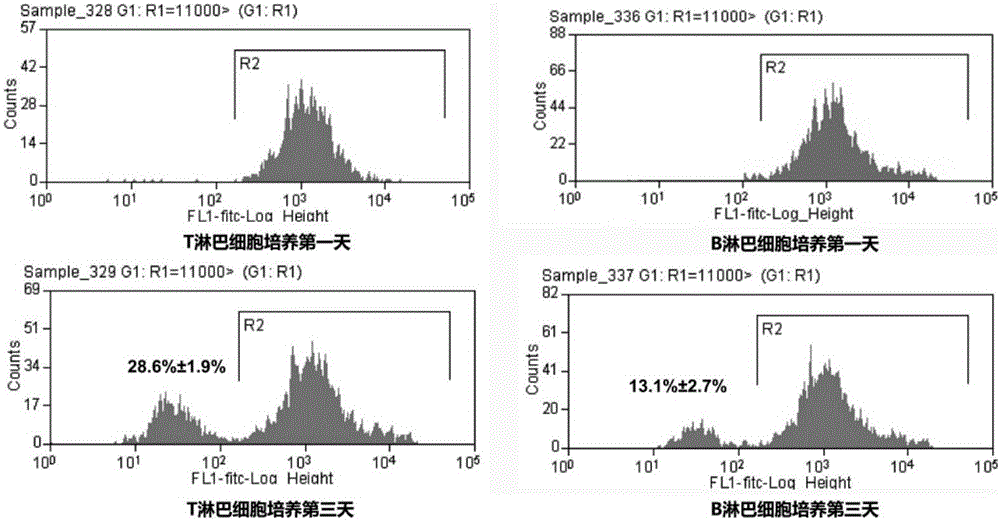

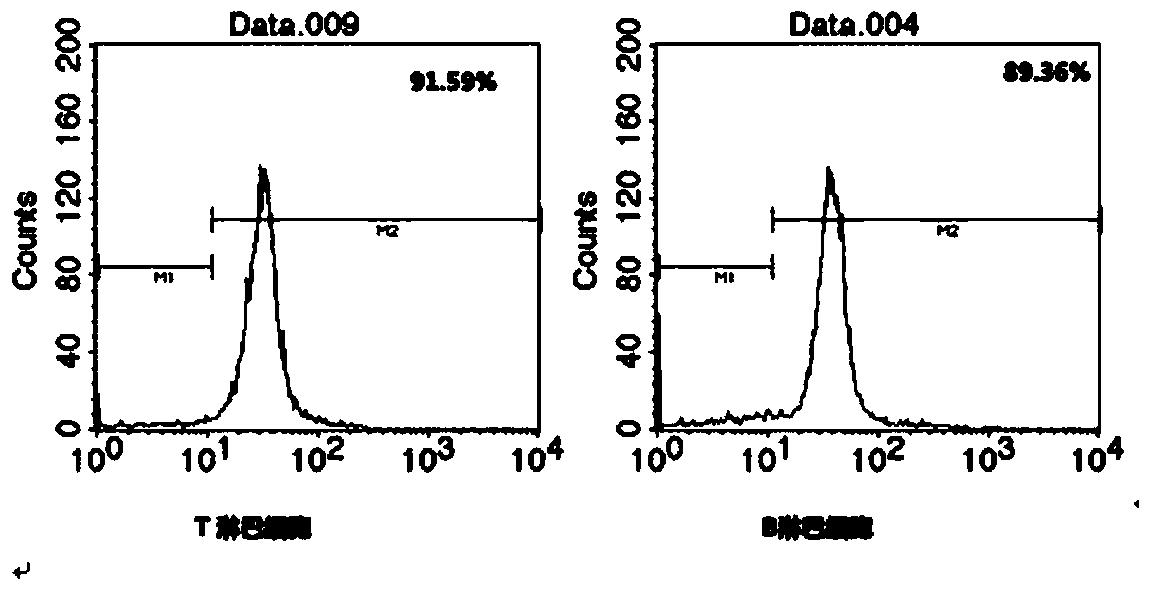

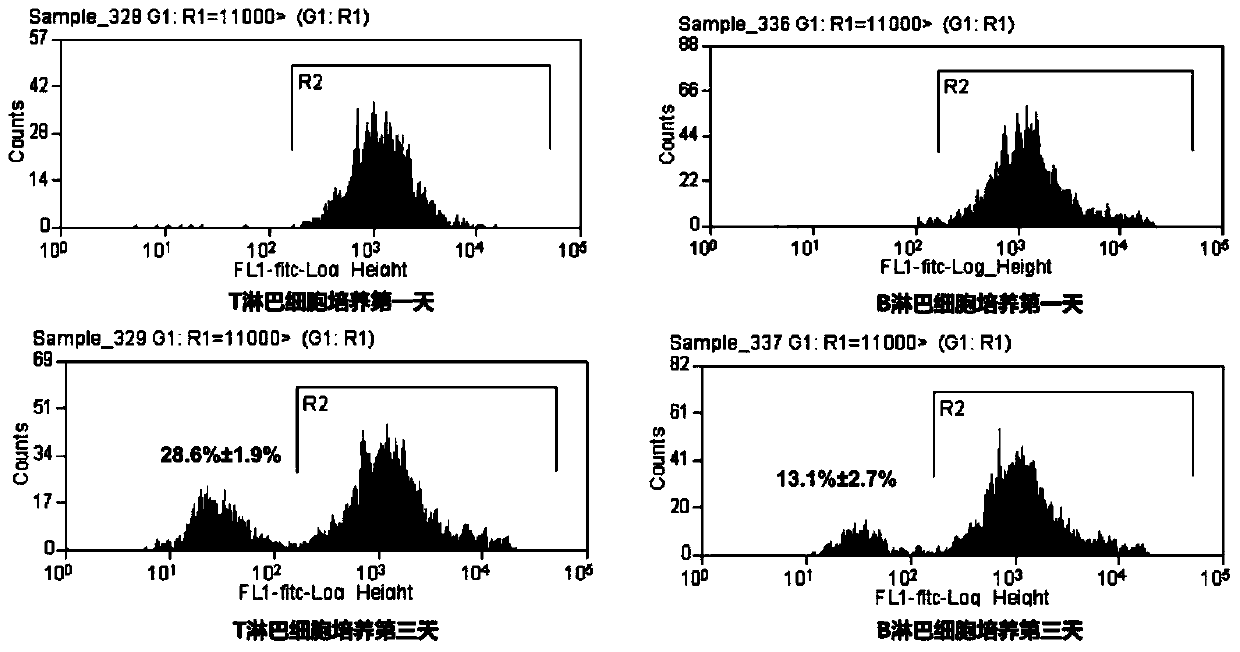

Method for simultaneous separation of T and B lymphocytes in peripheral blood

InactiveCN106085955AProliferate fastHigh activityBlood/immune system cellsLymphocyteDrug biological activity

The invention discloses a method for simultaneous separation of T and B lymphocytes in peripheral blood. The method is an improved nylon wool column separation method, can realize one-time simultaneous separation, so that two kinds of lymphocytes, namely T and B lymphocytes are obtained, cell yield is high, cross contamination is less, there is no effect on the biological activity of the cells, and the next step of the experimental study is easy to carry out.

Owner:CENT SOUTH UNIV

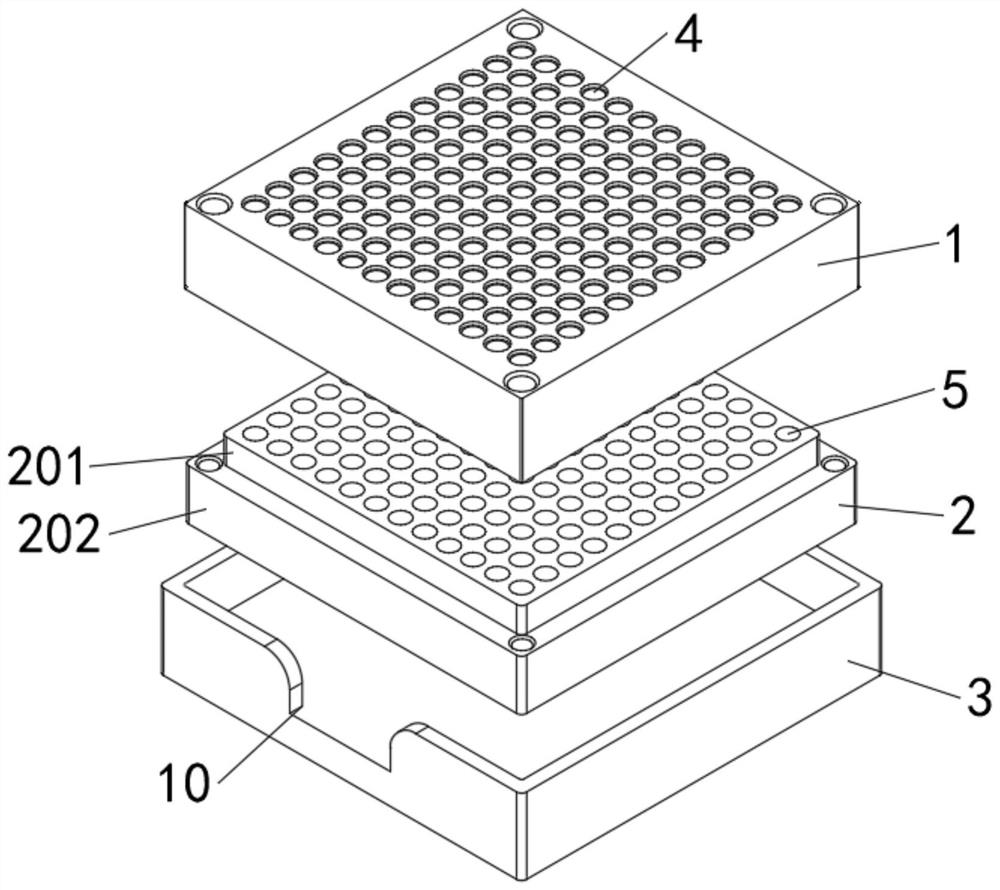

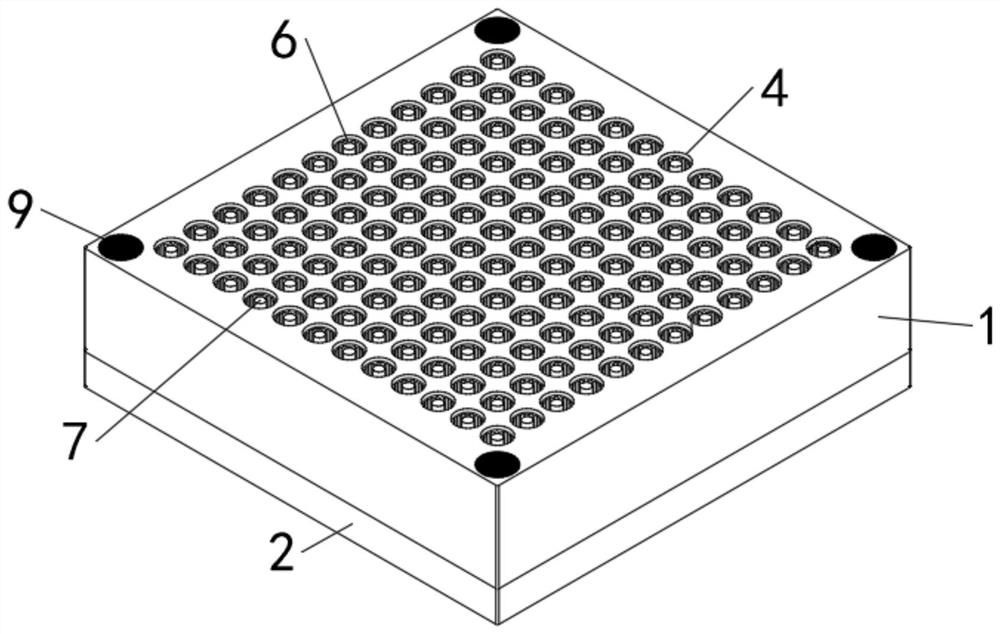

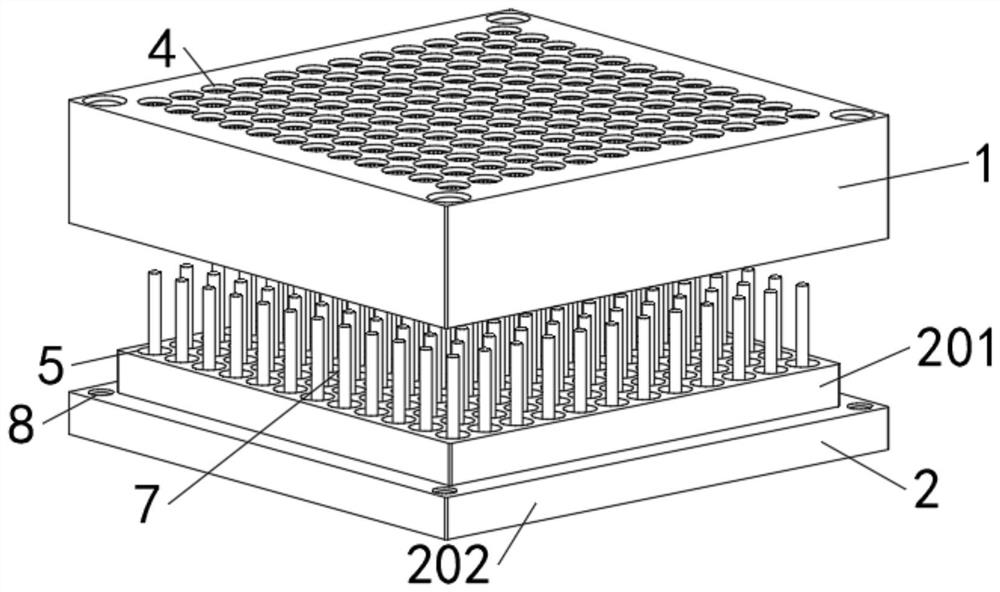

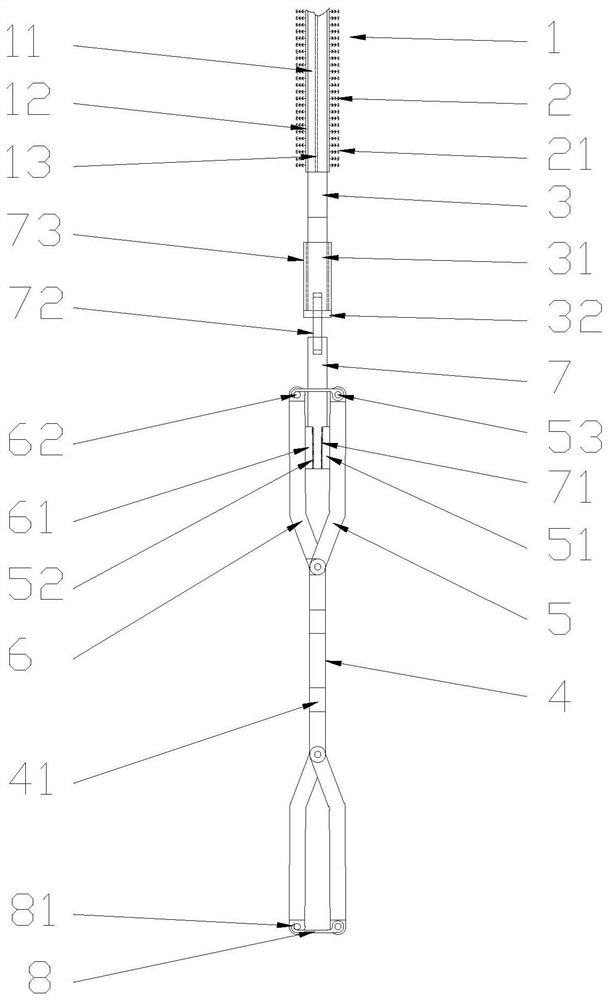

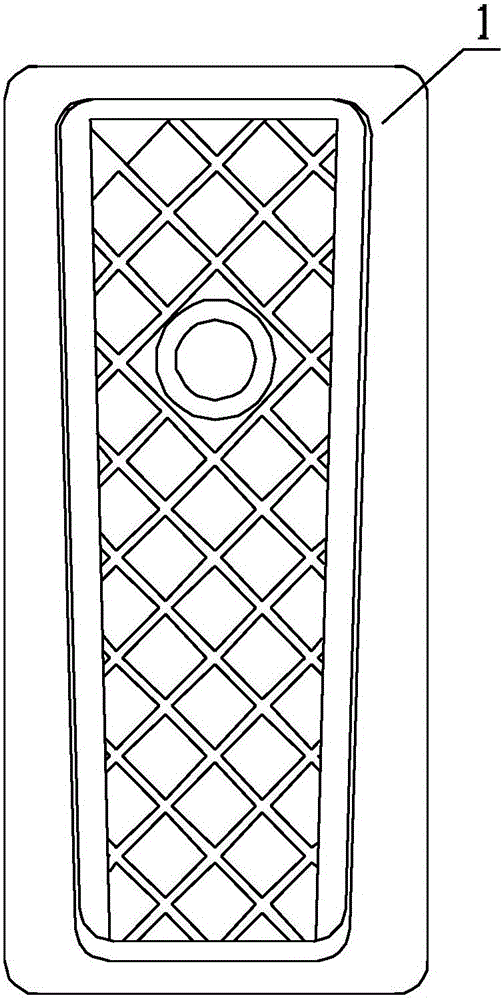

Machining die for eyeliner bristle head

PendingCN113729391AAvoid distortionPlay the role of positioning the perforation at the centerBristlePackaging toiletriesBristleEngineering

According to the technical scheme, the machining die is characterized by comprising an upper die body, a lower die body and a die bottom sleeve, a plurality of through holes are evenly formed in the upper die body, a plurality of guide holes are formed in the positions, corresponding to the through holes, of an upper plate body, annular tooth pipes are fixedly arranged in the through holes, guide columns are arranged in the guide holes, and the lower die body is fixedly connected with the lower die body. The guide columns are clamped in the annular toothed pipe, fixing holes are formed in the four corners of the upper die body and the four corners of the lower die body, fixing rods are arranged in the fixing holes, and a die bottom sleeve is clamped on the outer side of the upper die body and the outer side of the lower die body which are connected. The problems that the machining effect of a machining mold on eyeliner hair heads is poor, and when the whole machining mold is placed on a high-frequency vibration machine, the device is prone to displacement and poor in positioning effect due to the fact that nylon hair raw materials are vibrated by the high-frequency vibration machine are solved.

Owner:雅香丽化妆用品(深圳)有限公司

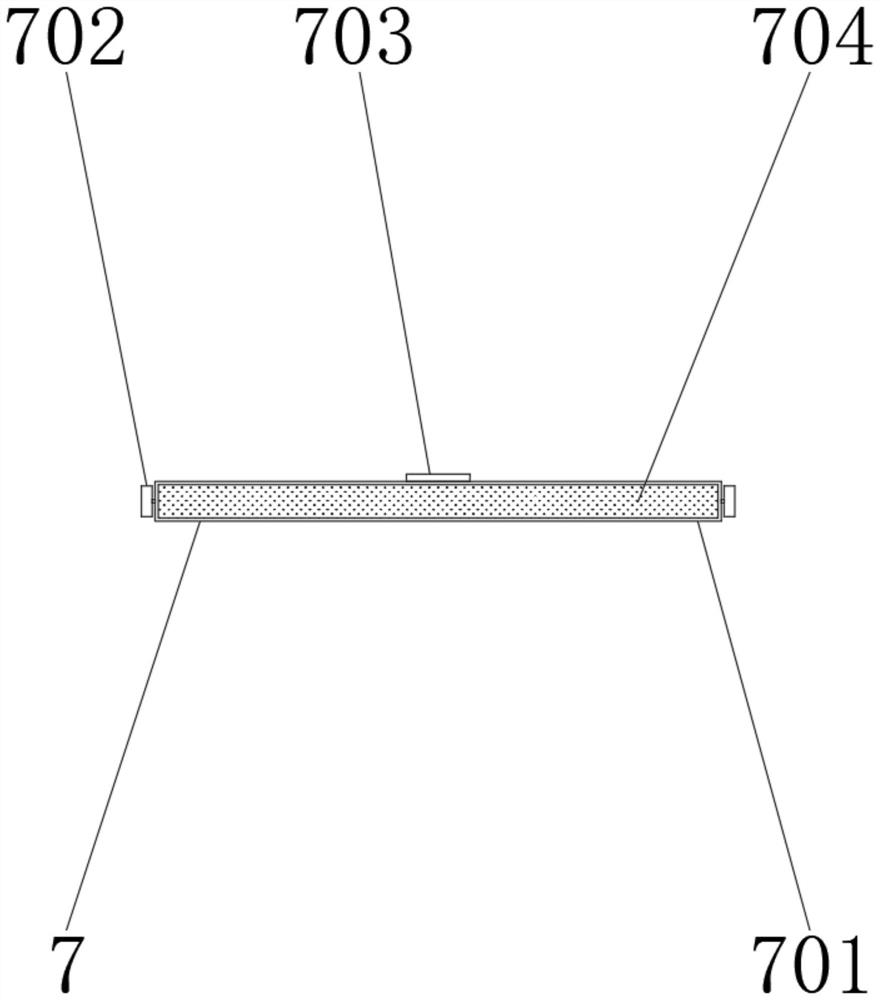

Length-adjustable hook-and-loop fastener

PendingCN111642863AEasy to install and connectImprove interchangeabilityHaberdasheryFastenerNylon wool

The invention relates to a hook-and-loop fastener with the adjustable length. The hook-and-loop fastener comprises a nylon hook surface body, a hook body, a nylon fluff surface body and nylon fluff, and is characterized in that the tail end of the nylon hook surface body is detachably connected with a positioning device; the positioning device comprises a positioning plate; a screw connecting holeis formed in the middle of the positioning plate; and detachable linkage assemblies detachably connected with the nylon hook surface body are symmetrically arranged at the two ends of the positioningplate. The detachable linkage assembly comprises a first limiting plate, a second limiting plate, a first inner layer and a second inner layer. A clamping assembly is arranged between the first innerlayer and the second inner layer, the clamping assembly comprises first oblique teeth and second oblique teeth, and a fastening assembly is arranged at the other end, opposite to the hinged positioning plate, of the first limiting plate. The hook and loop fastener has the beneficial effects that the hook and loop fastener is provided, mounting and positioning are convenient, and the length is adjustable.

Owner:瑞安市华升塑料织带有限公司

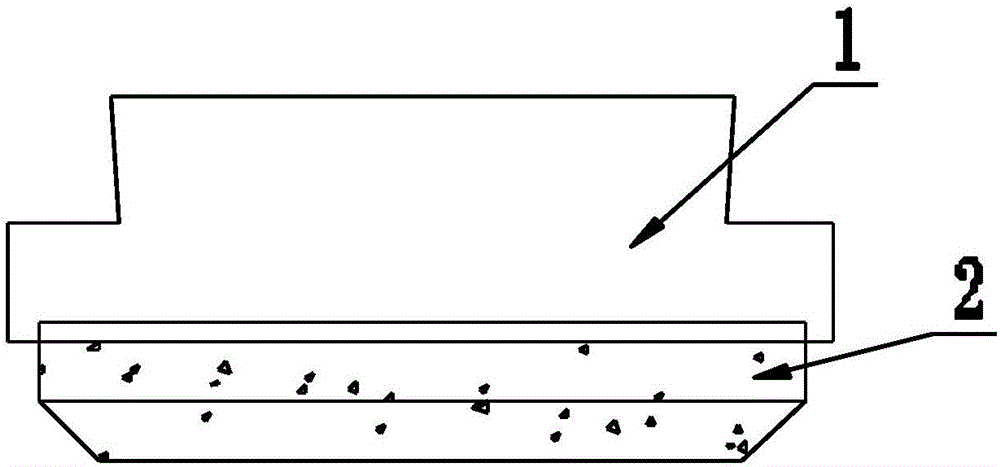

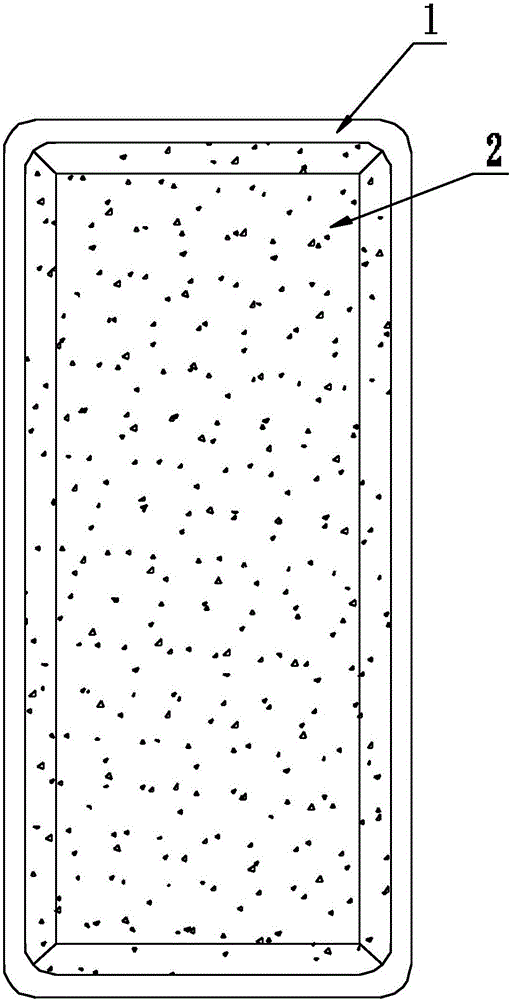

Resin fiber abrasive block and preparation method thereof

The invention discloses a resin fiber abrasive block and a preparation method thereof. The resin fiber abrasive block is composed of a clamping seat and a resin fiber grinding block pasted in the clamping seat. The resin fiber grinding block comprises nylon wool and mixed liquid adsorbed to the nylon wool. The mixed liquid comprises, by weight, 50-150 parts of binders, 40-130 parts of grinding materials and 5-10 parts of fillers. The resin fiber abrasive block has good copying performance and can be used for processing planes and uneven surfaces, no grinding crack or scratch is generated in the processing course, obtained processed surfaces are very fine and smooth and soft in luster, and has effects of natural silk-shaped luster and matte.

Owner:广东奔朗新材料科技有限公司

Wet transfer printing method for nylon wool electrostatic flocking cloth

InactiveCN103015240BEnhanced wash and light resistanceIdeal transfer rateFibre treatmentTransfer printing processInorganic saltsTextile printer

The invention discloses a wet transfer printing method for nylon plush electrostatic flocking cloth, which belongs to the technical field of electrostatic flocking fabric printing. Steps: use inorganic salt solution and organic acid solution to prepare the pretreatment solution; introduce the nylon plush electrostatic flocking cloth into the paddle filled with the pretreatment solution for padding; mix the wet nylon plush electrostatic flocking cloth with the printing The film is introduced into the calendering device in the composite state to transfer the pattern on the printed film to the plush surface of the nylon plush electrostatic flocking cloth, and the rolling device is introduced into the separation device to separate the printed nylon plush electrostatic flocking cloth and the printing The film is separated and the printed film is rolled up. At the same time, the printed nylon plush electrostatic flocking cloth is introduced into the oven for drying and cooled; then introduced into the steamer to steam and fix the color, and after the steamer is washed, softened and dried. Get printed nylon plush electrostatic flocking cloth. Advantages: The printed pattern is clear and bright and full, and the effect of washing and sun resistance is enhanced; it embodies energy saving; embodies environmental protection, simple process and high production efficiency.

Owner:XINTAI FLOCKING CHANGSHU CITY

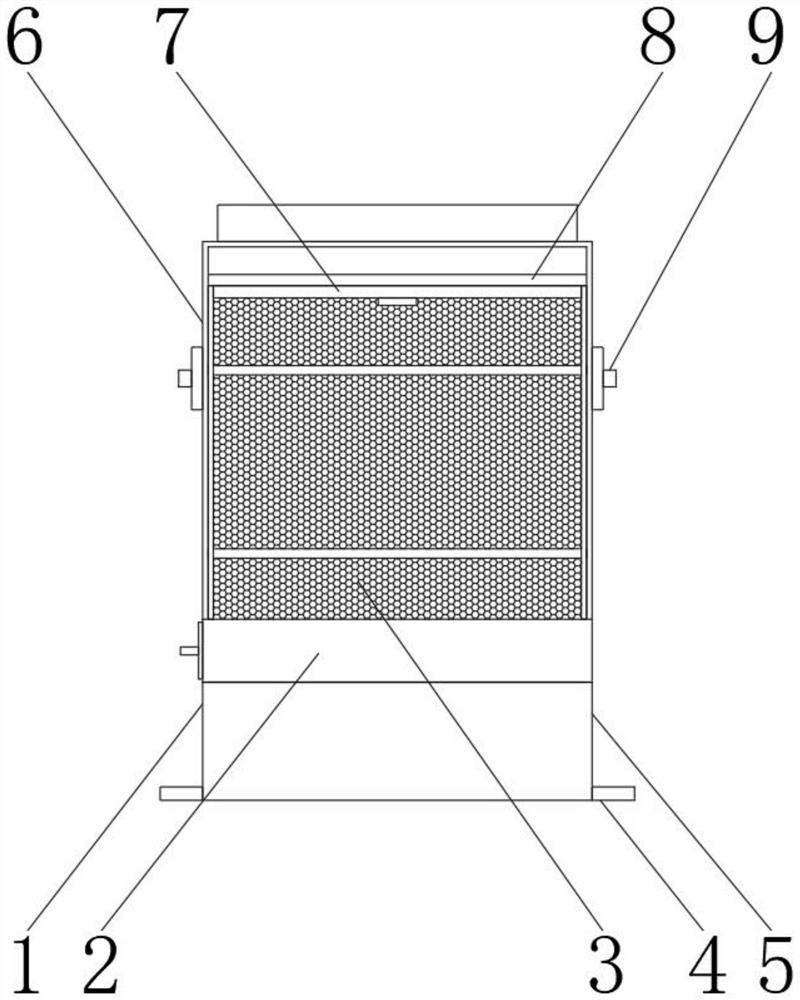

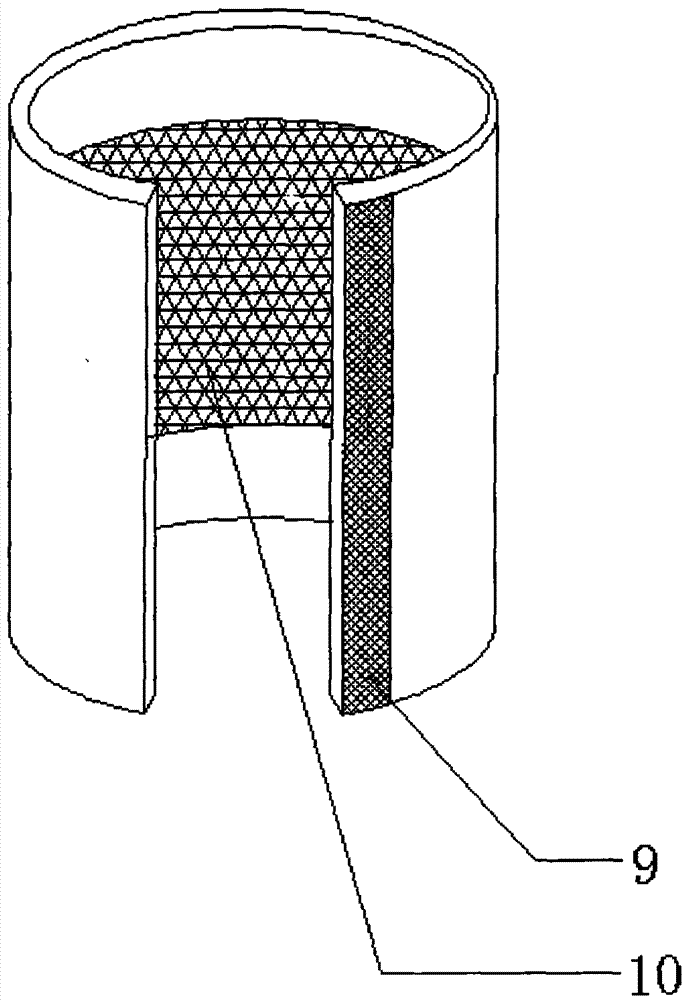

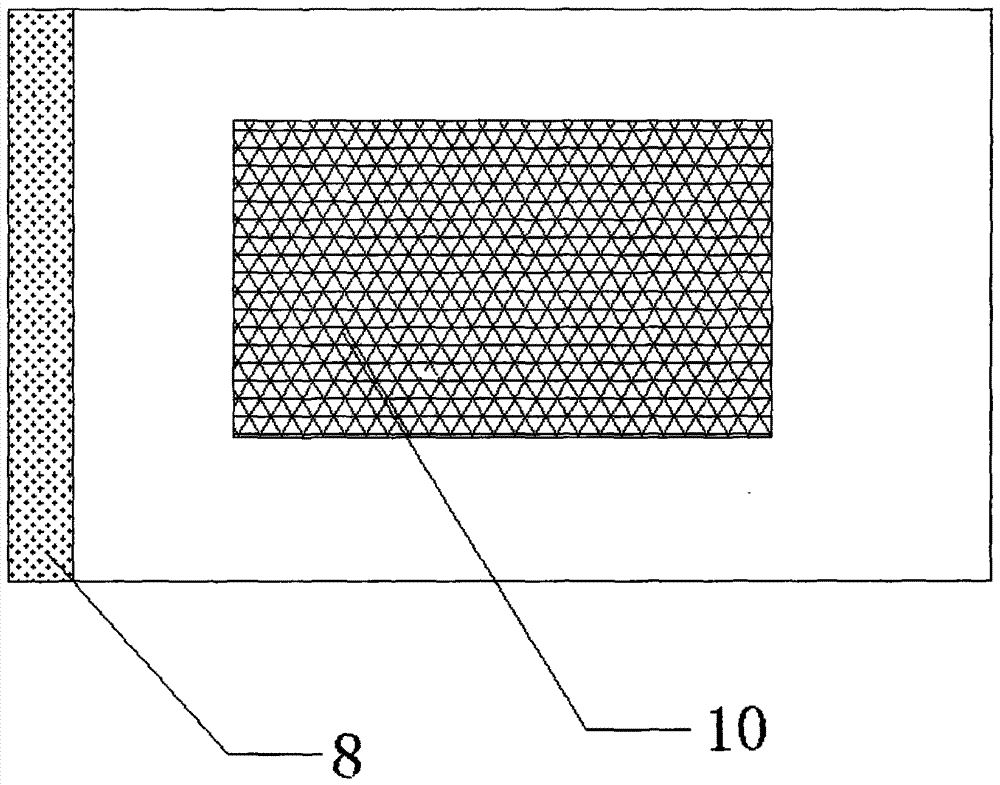

Sewage filtering equipment for leather processing

InactiveCN113813665ASimple structureEasy to operateStationary filtering element filtersSewageWaste material

The invention discloses sewage filtering equipment for leather processing. The sewage filtering equipment comprises a main body, a base is arranged on the outer surface of the lower end of the main body, mounting pieces are arranged on the outer surfaces of the two sides of the base, and a waste collecting mechanism is arranged on the outer surface of the upper end of the base. The sewage filtering equipment for leather processing is provided with the waste collecting mechanism and a cleaning mechanism, when the equipment is used, waste in sewage enters a collecting box through a waste collecting opening in the front end of an upper cabinet body after being washed, when the equipment is full of the waste, the collecting box is taken out by pulling a first handle, and the waste is poured out of the collecting box; and through the arranged cleaning mechanism, when waste appears on a filter screen, a second handle can be pulled to drive a movable rod, the waste on the filter screen is swept down through a nylon brush on the movable rod, the situation that the waste is gathered on the filter screen to cause blockage is prevented, and a better use prospect is brought.

Owner:JIANGXI HOPU HIGH TECH COATED FABRIC CO LTD

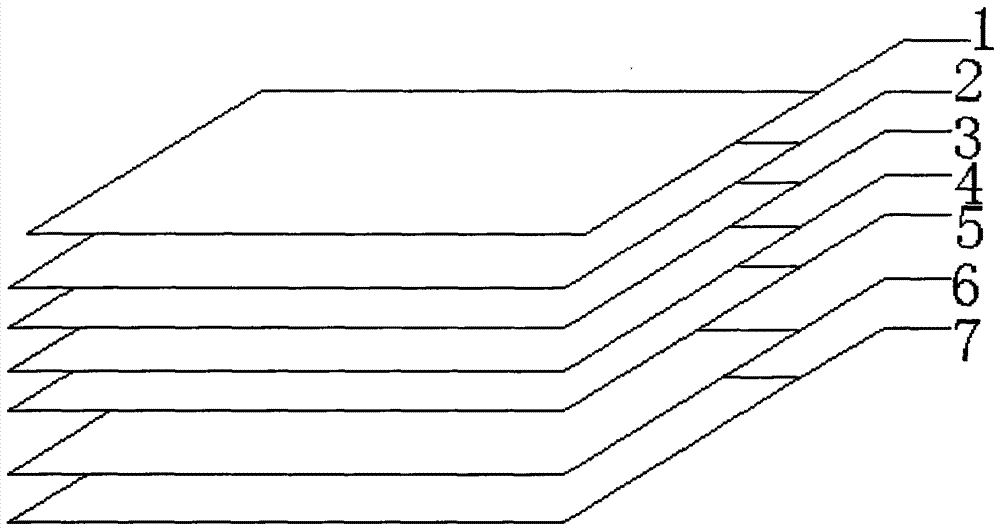

A new type of medical nursing bandage

The invention discloses a novel medical nursing bandage, which belongs to the field of medical appliances. A new type of medical nursing bandage, the bandage at least includes non-woven fabric, carbon fiber, phenolic resin, silicon carbide, bamboo charcoal fiber cloth, epoxy resin, PU layer, the above-mentioned layers are connected by a pressing method, and are arranged in the middle of the bandage There is a medicine bag, one end of the bandage is provided with nylon micro-hooks, and the outside of the right side of the other end is provided with nylon silk. The present invention has the advantages of comfort and safety, good air permeability, high hardness, light weight, good X-ray transmittance, and strong water resistance. Even after the affected limb is exposed to water, it can effectively ensure the dryness of the affected part, is not afraid of secondary immersion, and is easy to operate. The advantages.

Owner:张灿萍

A method for simultaneously isolating peripheral blood t and b lymphocytes

InactiveCN106085955BFluffy stretchImprove adsorption capacityBlood/immune system cellsLymphocyteDrug biological activity

The invention discloses a method for simultaneous separation of T and B lymphocytes in peripheral blood. The method is an improved nylon wool column separation method, can realize one-time simultaneous separation, so that two kinds of lymphocytes, namely T and B lymphocytes are obtained, cell yield is high, cross contamination is less, there is no effect on the biological activity of the cells, and the next step of the experimental study is easy to carry out.

Owner:CENT SOUTH UNIV

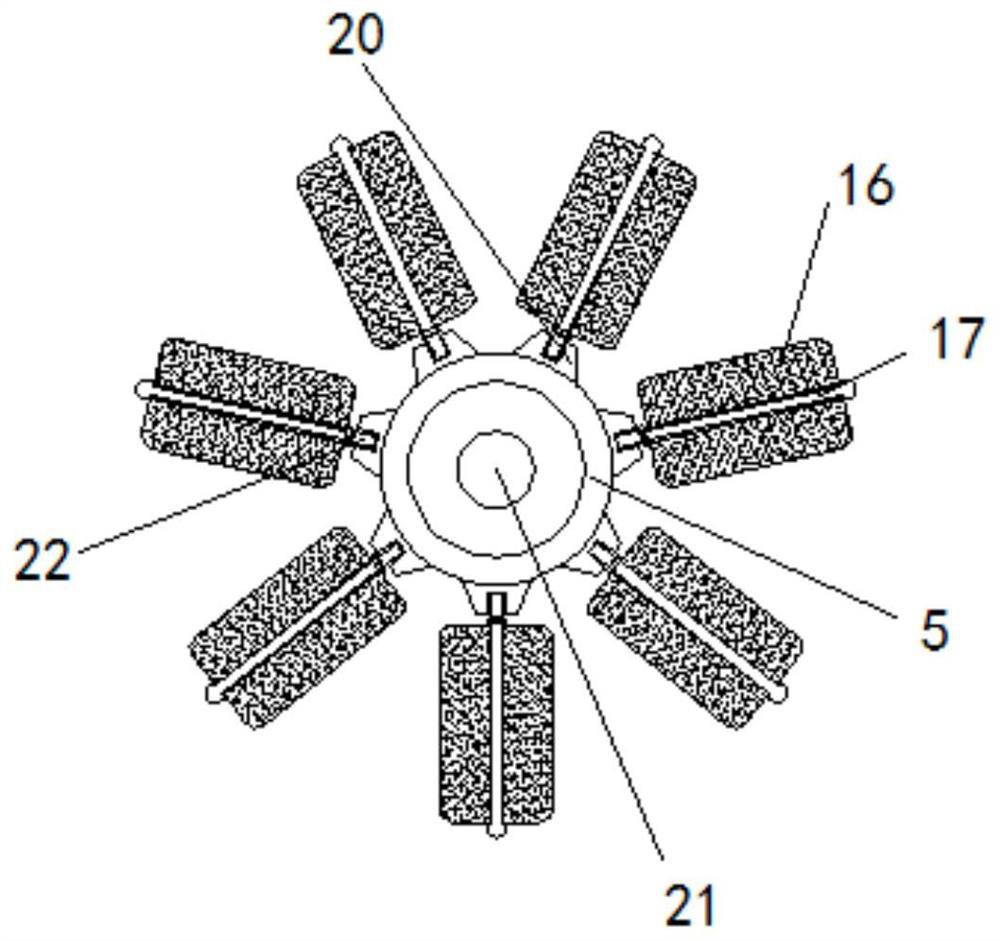

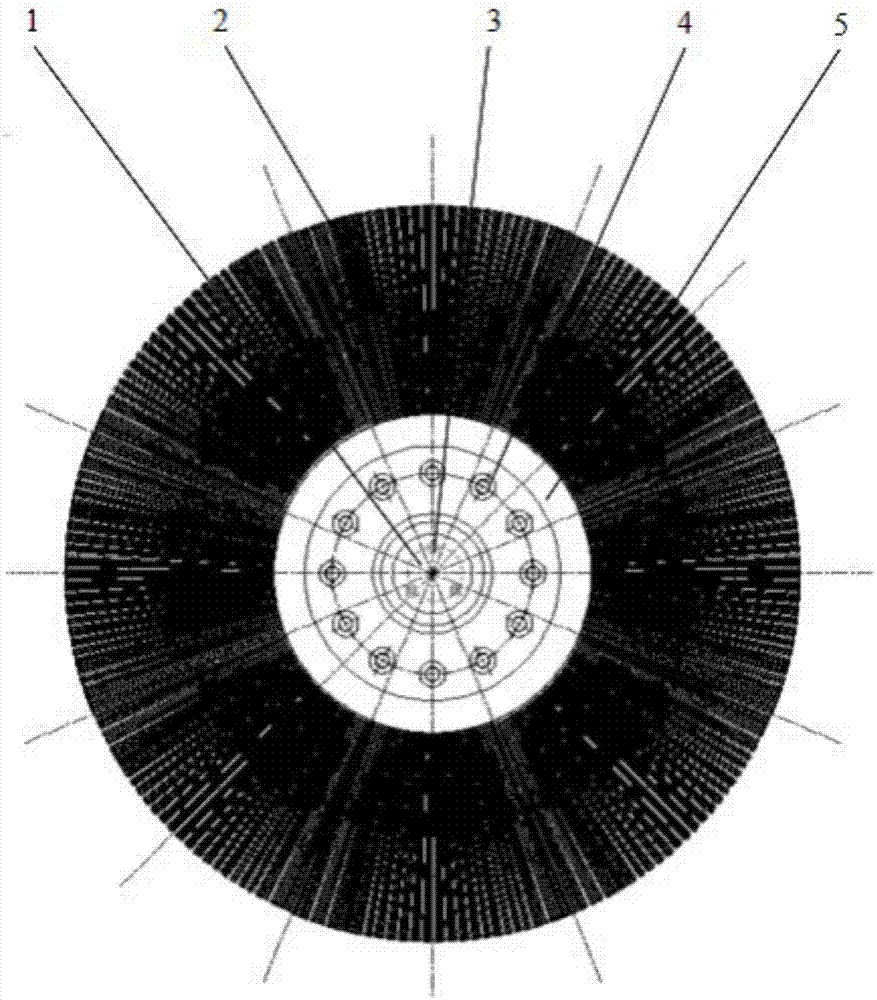

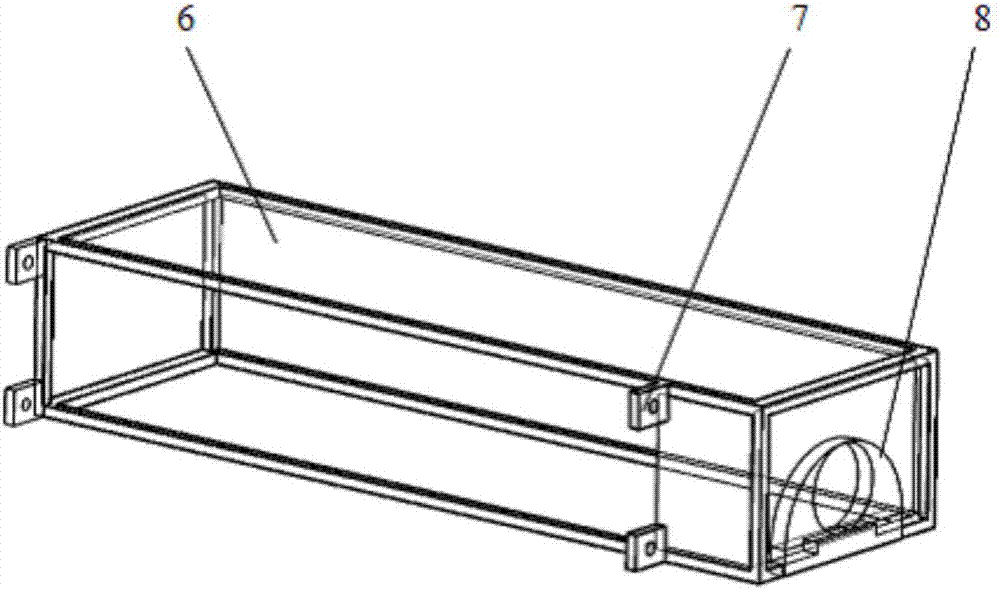

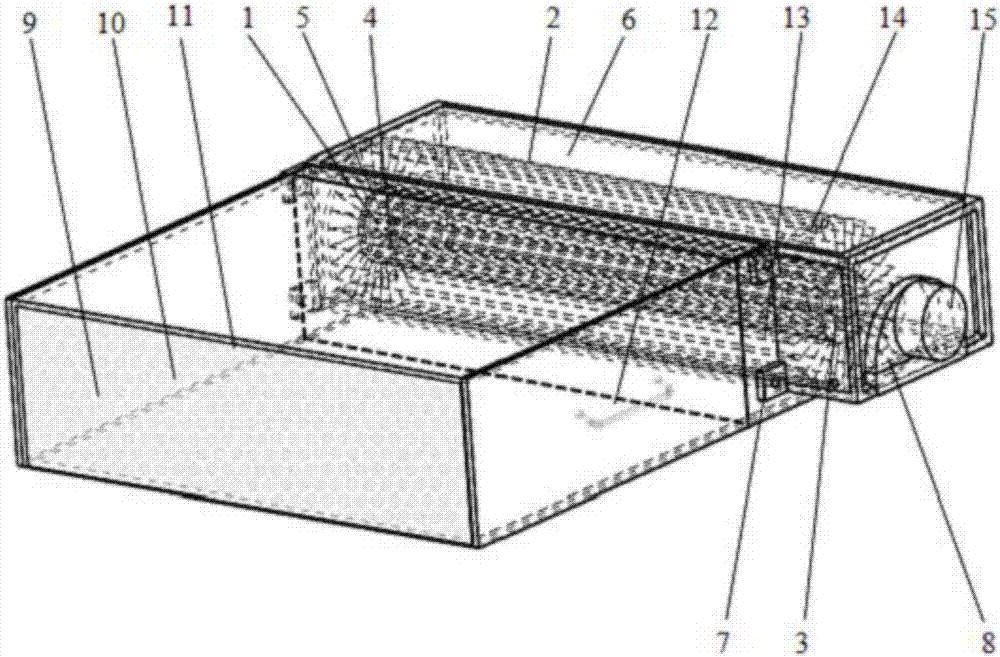

Transverse-axis roller type cleaning unit for road cleaning vehicle

The invention relates to a transverse-axis roller type cleaning unit for a road cleaning vehicle. The transverse-axis roller type cleaning unit mainly comprises a transverse-axis roller device, a brush sealing box, a garbage collecting box and a box base, wherein the transverse-axis roller device comprises a roller base and a brush, and the brush is formed by a plurality groups of nylon bristles which are evenly distributed on the surface of the roller base; the transverse-axis roller device is horizontally mounted on the rack of the brush sealing box through a rotary shaft, the garbage collecting box is mounted right in front of the transverse-axis roller device through a fixing rack, and the rear cover plate of the garbage colleting box is provided with air vents and a filter screen; a direct-current motor is mounted on a motor base. The transverse-axis roller type cleaning unit has the advantages that by the transverse-axis roller type cleaning unit, the defects that a modern road cleaning vehicle is slow in operation, low in cleaning efficiency, high in energy consumption, and the like are overcome, a road cleaning effect and use safety are increased, and the cleaning unit is simple in structure, low in part cost, long in service life and capable of meeting the development requirements of energy conservation and emission reduction and green energy.

Owner:江苏坦道智能设备有限公司

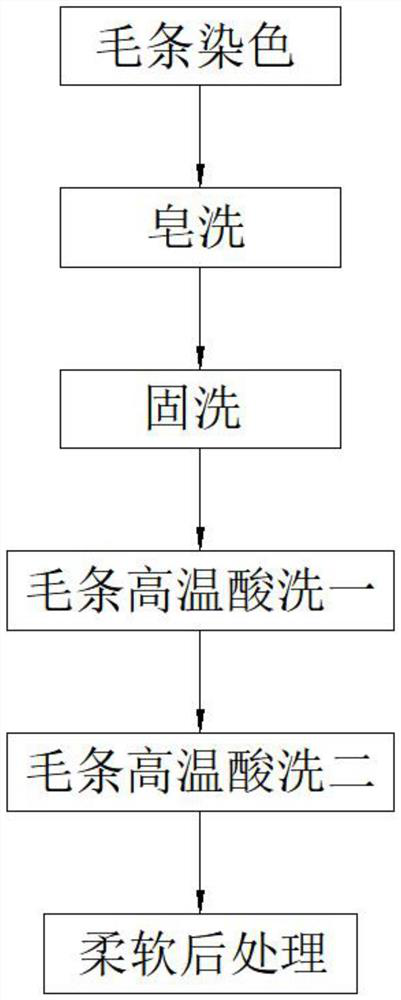

Nylon wool top dyeing process capable of improving nylon spinning operation conditions

InactiveCN111621999AExcellent adhesionImprove healthDry-cleaning apparatus for textilesDyeing processAcetic acidPolymer science

The invention discloses a nylon wool top dyeing process capable of improving nylon spinning operation conditions. The nylon wool top dyeing process comprises the following steps: step one, wool top dyeing: loading nylon wool balls into a dye vat, adding a penetration enhancer, acetic acid and a leveling agent at room temperature, operating for 10 minutes, then adding a dye, and operating for 10 minutes, then raising the temperature to 98 DEG C at the speed of 0.5-1 DEG C / min, keeping the temperature for 30-60 minutes, reducing the temperature to 80 DEG C, and draining water; step two, soaping:adding a soaping agent at room temperature, operating for 10 minutes, raising the temperature to 60 DEG C, keeping the temperature for 30 minutes, and draining water; and step three, color fixing: adding a color fixing agent and acetic acid at room temperature, operating for 10 minutes, raising the temperature to 70 DEG C, keeping the temperature for 20 minutes, and draining water. The nylon fibers are subjected to color fixing treatment, so that various wet treatment fastnesses such as friction, water washing and sweat stain of the nylon fibers are improved; and meanwhile, through a reasonable high-temperature pickling process, the adhesion effect of the nylon fibers is improved, the operation condition during nylon blended spinning is improved, and the production efficiency is improved.

Owner:ZHANGJIAGANG YANGZI DYEING & FINISHING CO LTD

A kind of writing brush and its manufacturing process

The invention discloses a hairbrush and a manufacturing process of the hairbrush. By completely optimizing the processing of nylon wool, treatment of animal wool and variety selection and match of the wool, the obtained hairbrush has high elasticity and high ink holding capacity in both writing and painting, a user can write words comfortably, the words written with the hairbrush are vigorous and forceful, stretch long and have a high artistic effect, and the hairbrush varies in hardness when used for writing. The hairbrush has high quality and good market prospects. As the nylon wool technology is improved and damage to the animal wool is reduced by improving the animal wool technology, the hairbrush is more elastic and durable and can be kept for a long period.

Owner:湖州市善琏心远笔斋股份有限公司

Brushes for middle and primary school students

The invention discloses a special writing brush for primary and secondary school students. The aperture of the writing brush is 0.92-0.98 cm; and the exposed tip of the writing brush is 37-53 mm. The writing brush is manufactured according to the weight percentage as follows: a main tip is manufactured by wool and nylon wool in a proportioned manner; the weight of the wool accounts for 60-80% of the total weight of the main tip; the weight of the nylon wool accounts for 20-40% of the total weight of the main tip; a subsidiary tip comprises a first tip, a second tip, a third tip, a fourth tip and a fifth tip; specifically, the weight of the first tip accounts for 25-35% of the total weight of the subsidiary tip; the weight of the second tip accounts for 20-25% of the total weight of the subsidiary tip; the weight of the third tip accounts for 18-22% of the total weight of the subsidiary tip; the weight of the fourth tip accounts for 15-20% of the total weight of the subsidiary tip; the weight of the fifth tip accounts for 6-12% of the total weight of the subsidiary tip; protective hair is manufactured from wool and horsehair, wherein the wool is located on the upper part of the protective hair, and the weight of the wool accounts for 65-75% of the total weight of the protective hair; the horsehair is located on the bottom part of the protective hair, and the weight of the horsehair accounts for 25-35% of the total weight of the protective hair; and the wool is produced in the Yangtze River delta. According to the special writing brush, the writing elasticity of the writing brush accords with the practice characteristics of the students; the students can handle the brush easily; the tip ending is facilitated; the writing brush is not deformed easily, and the service life is long; and the writing brush is most applicable to the nine-year compulsory education students.

Owner:项城市汝阳刘笔业有限公司

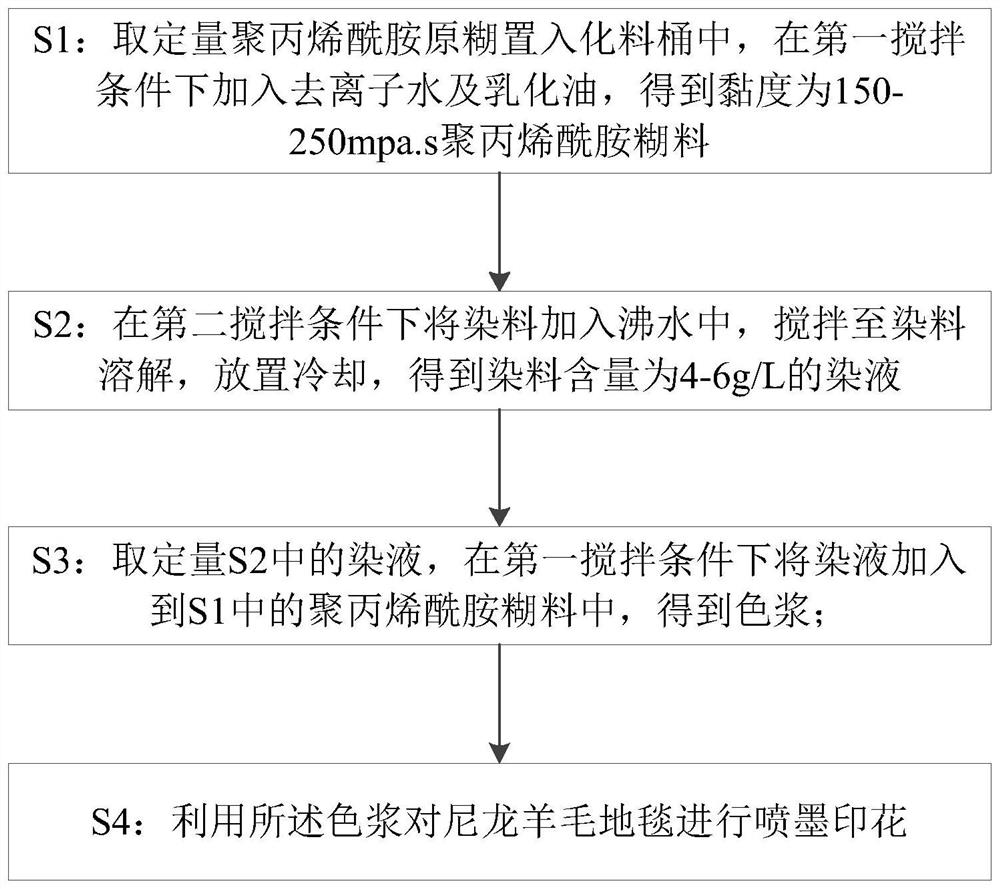

Ink-jet printing method for nylon wool carpet

PendingCN113882173AImprove efficiencyReduce labor intensityDyeing processTextile printerPolymer science

The invention discloses an ink-jet printing method for a nylon wool carpet, belongs to the technical field of ink-jet printing of carpets, and can solve the problems that existing paste is difficult to dissolve and degrade. The method comprises the following steps of putting quantitative polyacrylamide raw paste into a material melting barrel, and adding deionized water and emulsified oil under a first stirring condition to obtain a polyacrylamide paste material with the viscosity of 150 to 250mpa. S; adding a dye into boiling water under a second stirring condition, stirring until the dye is dissolved, and standing and cooling to obtain dye liquor with the dye content of 4 to 6g / L; taking quantitative dye liquor in S2, and adding the dye liquor into the polyacrylamide paste in S1 under the first stirring condition to obtain a color paste; and carrying out ink-jet printing on the nylon wool carpet by using the color paste.

Owner:BINZHOU COC CARPET

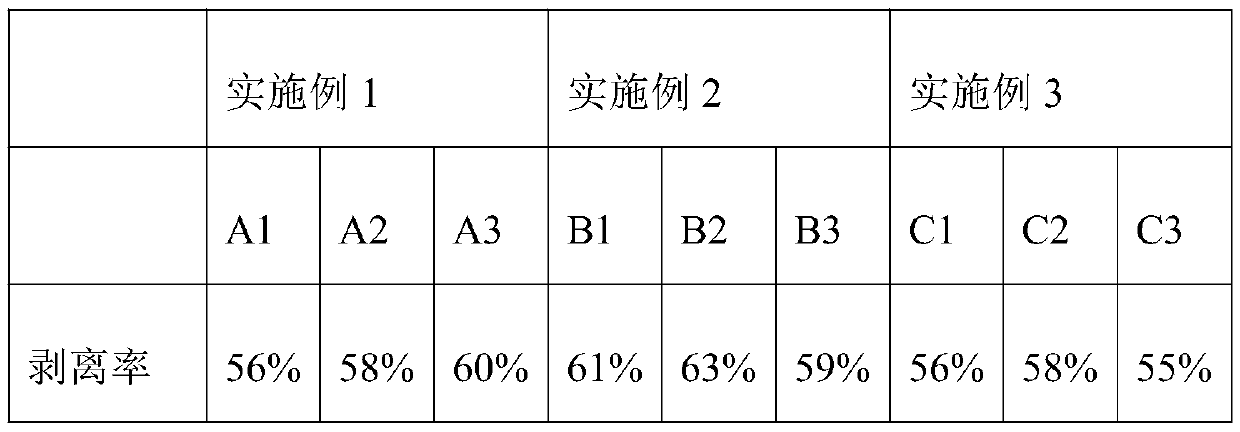

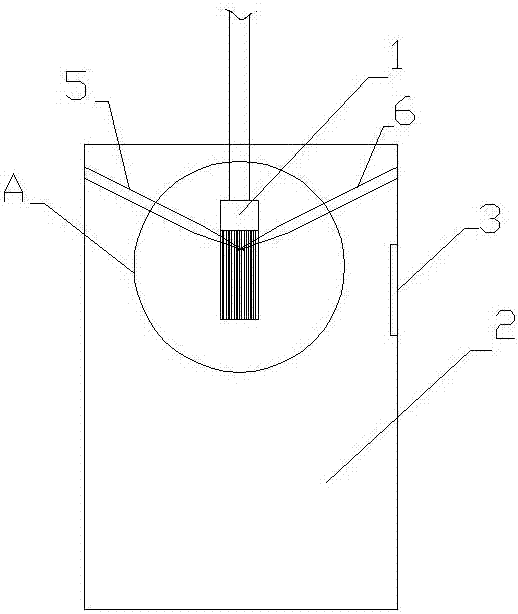

Cell stripping method

PendingCN110904040AImprove stripping efficiencyQuality improvementCell dissociation methodsBlood/immune system cellsLymphocytic cellDistilled water

The invention provides a cell stripping method, and specifically relates to the technical field of medicines. The cell stripping method comprises the following steps of S1, putting 40-80g of nylon hairs in a beaker, adding 80-160ml of distilled water, covering the beaker with aluminium foil, performing boiling over for 15-20 min, performing cooling to the room temperature, and performing pouring to a funnel with a filter paper to filter off the water; S2, spreading the nylon hairs in a tray laid with a gauze, placing the tray in a temperature box of 30-45 DEG C, and performing drying for 30-40h; S3, taking a 50ml syringe, configuring a rubber tube with a clamping head at a syringe opening, placing the nylon hairs into the syringe, then wrapping the syringe with tinfoil, and placing the coated syringe in a sterilizing box for sterilization; S4, stuffing the syringe with cell culture liquid of 35-40 DEG C, and performing standing for 30 minutes; S5, diluting the cell liquid to be stripped with the culture liquid of 35-40 DEG C until the concentration is 4.9 *10<7>-5.1 *10<7> cells / ml; and S6, adding the cellular liquid in the S5 into the syringe, performing incubation under 35-40 DEG C for 50-70 min, and performing centrifugation, namely T lymphocyte stripping. Through the adoption of the cell stripping method disclosed by the invention, the stripping efficiency and the stripping quality of T lymphocyte can be improved.

Owner:JIANGSU JORTEN PHARMA CO LTD

Cleaning device utilizing static electricity to clear hair

InactiveCN107049167AAchieve cleaningAchieve clearingCarpet cleanersFloor cleanersEngineeringHair streams

A cleaning device for removing hair by using static electricity, comprising a broom and a dustbin. The hair removal port is provided with a left scraper and a right scraper which are connected to the box through a spring. Combs made of metal are provided on the left scraper and the right scraper. The limit device keeps the left scraper and the right scraper in a horizontal state without external force; a push rod is provided in the cavity of the handle body of the broom handle, and the lower end of the push rod extends out of the broom handle and is connected with a push plate . In the process of pushing the push rod downward, the device uses the push plate to push the left scraper and the right scraper apart to open the hair removal port for the broom hair to extend into the box, and in the process of pulling out the broom hair, the left scraper The comb teeth on the board and the right scraper are inserted into the broom bristles, and the hair on the broom bristles is scraped off into the dustbin, which is simple, convenient and hygienic.

Owner:翟志磊

Make-up brush head with new conception

The traditional make-up brush head is mainly made of animal fur or artificial synthetic materials, such as nylon fiber and the like. The quality, the performance and the price of the brush head are determined by material thereof. The animal fur has better performance but high cost and has big possibility of relating to moral contents, such as animal protection and the like, thus bringing difficulty for batch production; although artificial synthetic materials, such as nylon fiber and the like avoid the problem of animal protection and have low cost, artificial synthetic materials are not ideal on the aspects of make-up feel, using comfort level and quality, and few users have allergy, thus seriously affecting the welfare of consumers. The make-up brush head with new conception chooses the hair of people to serve as a raw material and utilizes the processing technology similar to animal fur, which lowers cost, avoids harming animals, ensures better using sense and stable quality, lowers the allergy risk, and fully performs the peculiar advantages of the hair of the human body to serve as the make-up brush head.

Owner:徐超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com