Patents

Literature

64results about How to "Ink evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

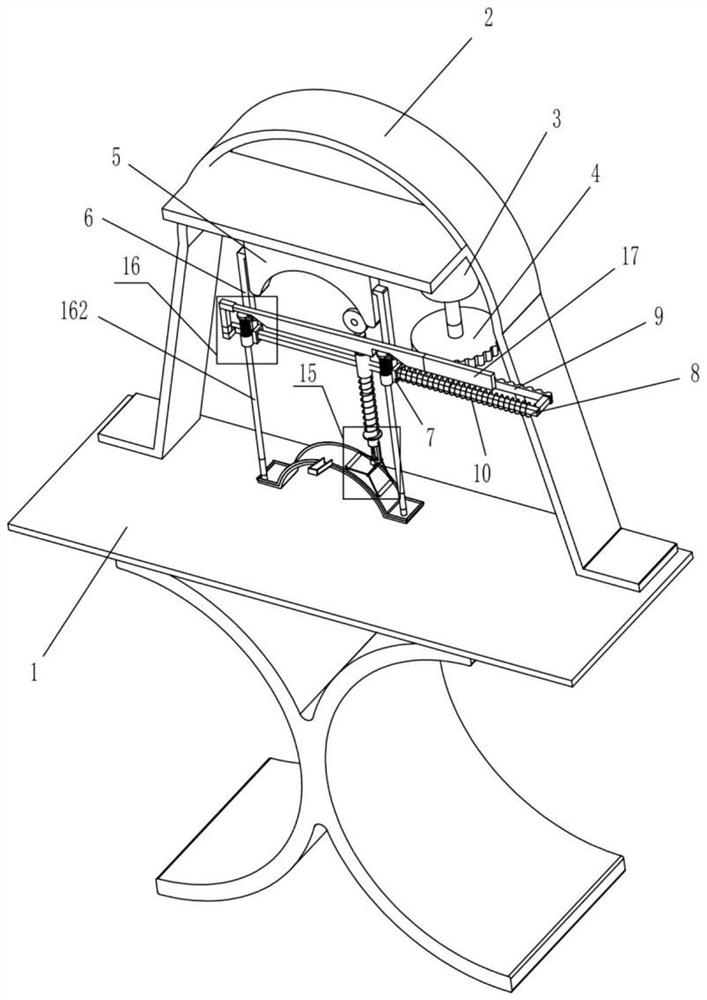

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

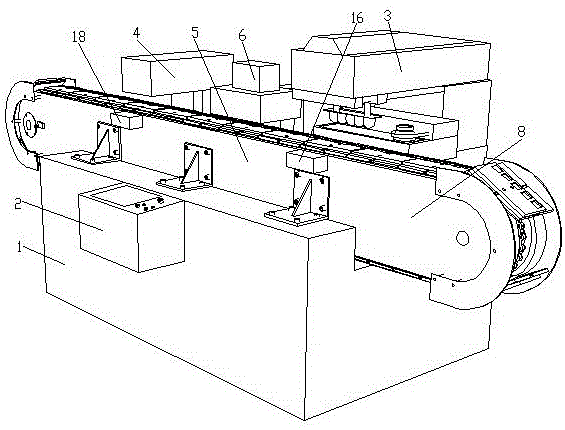

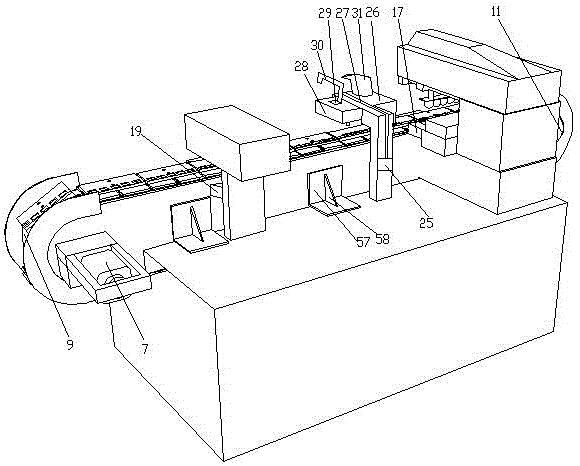

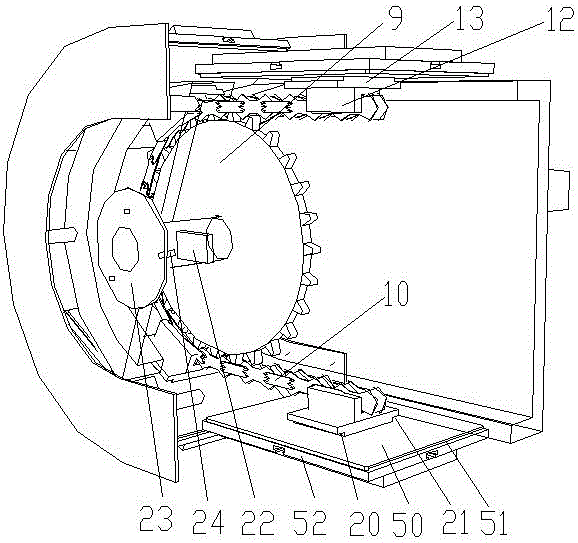

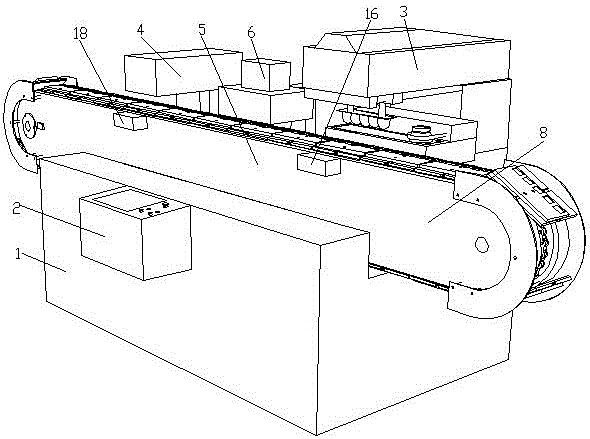

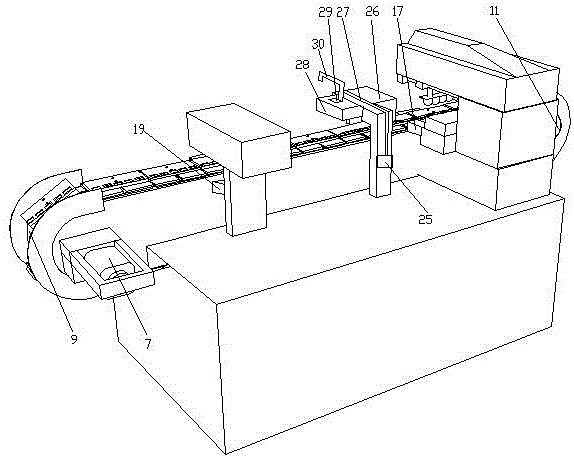

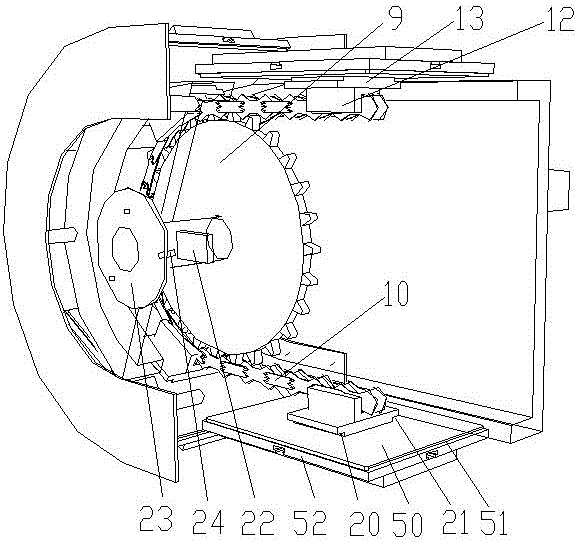

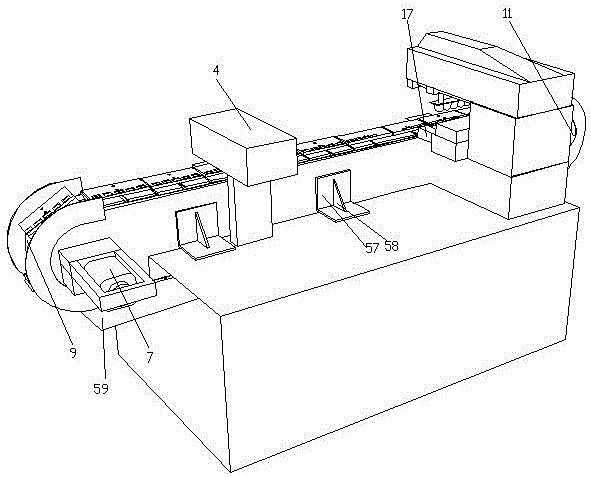

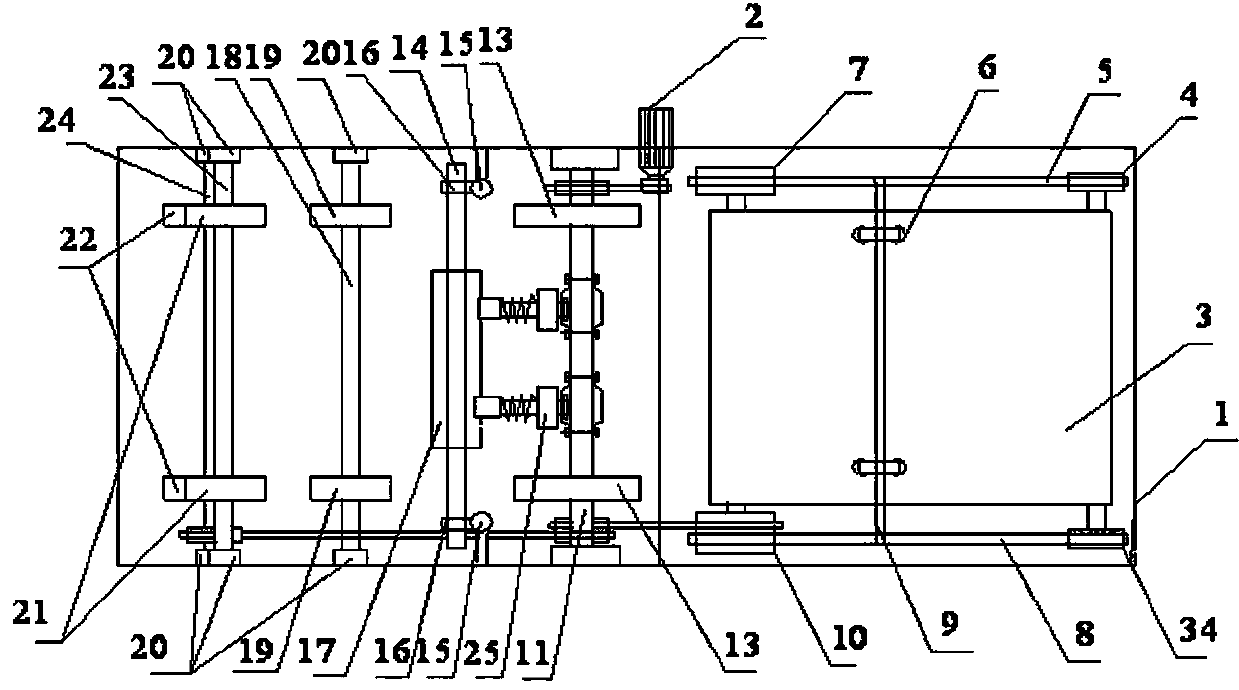

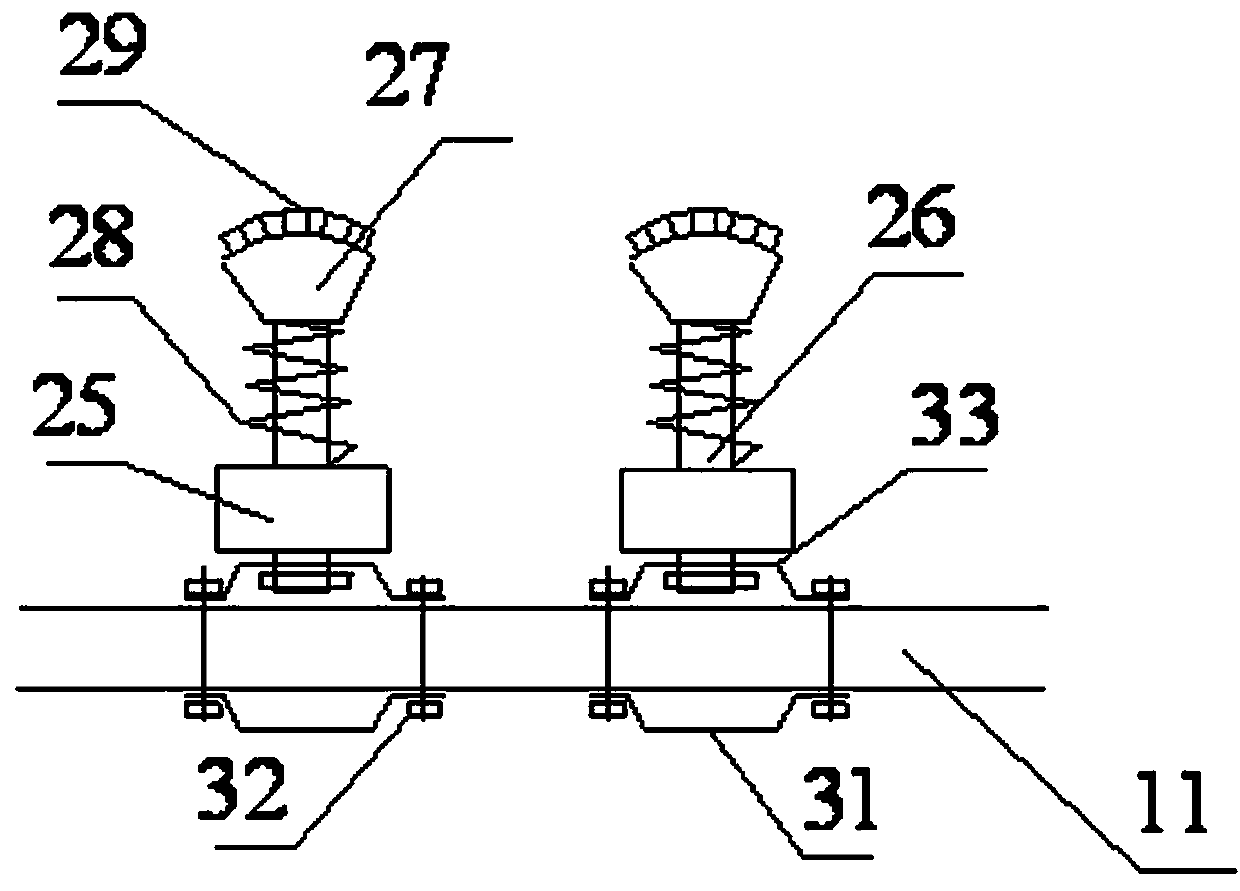

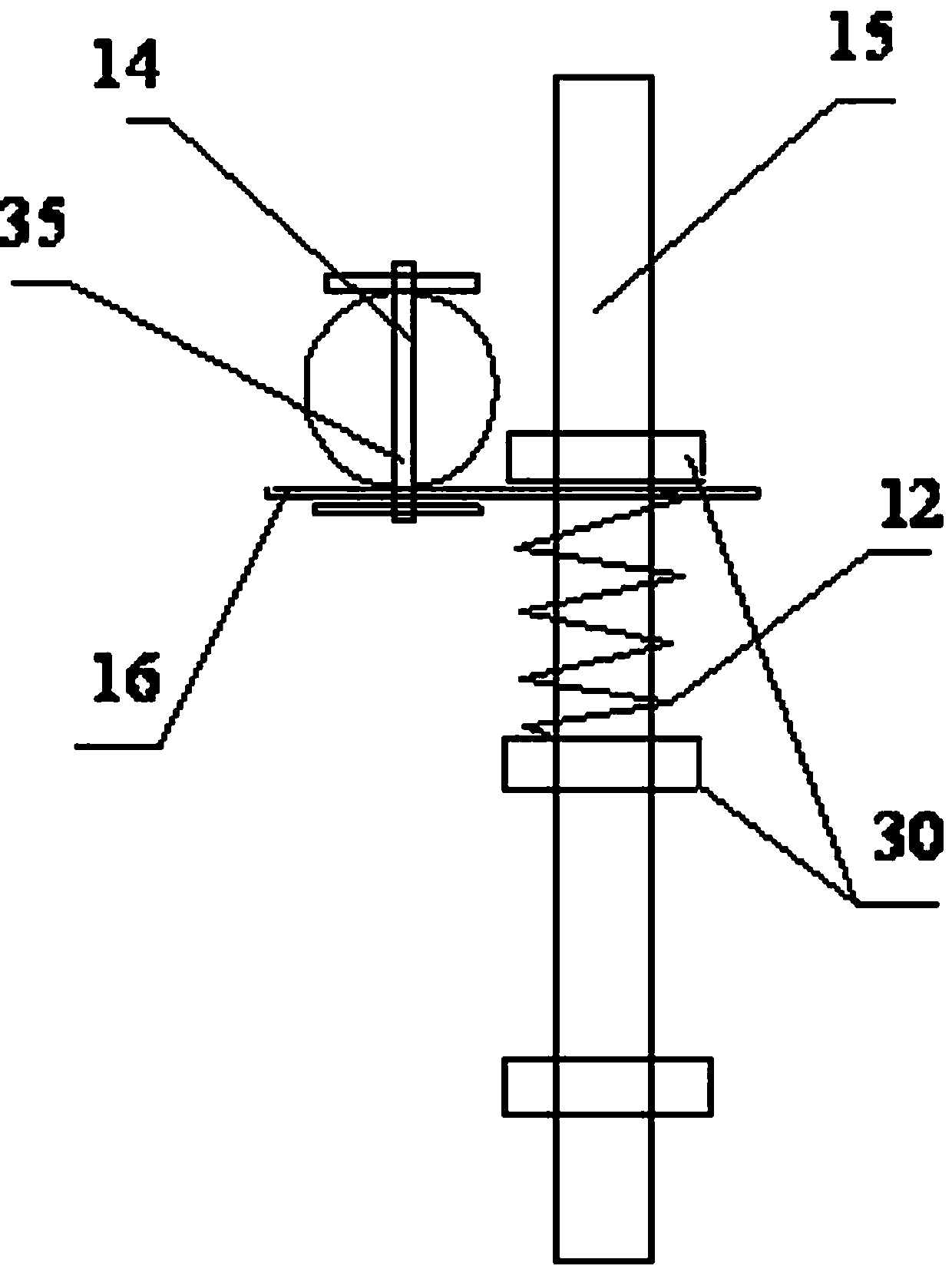

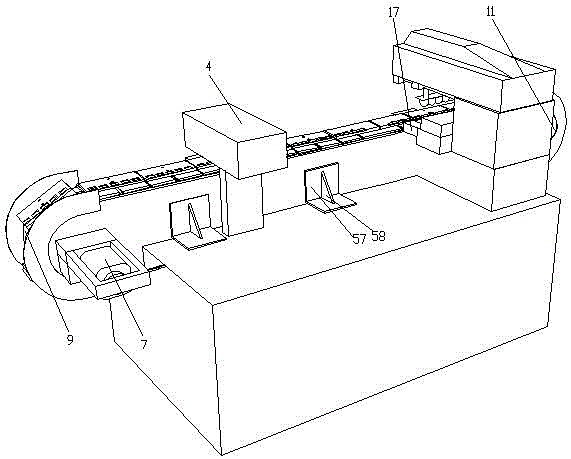

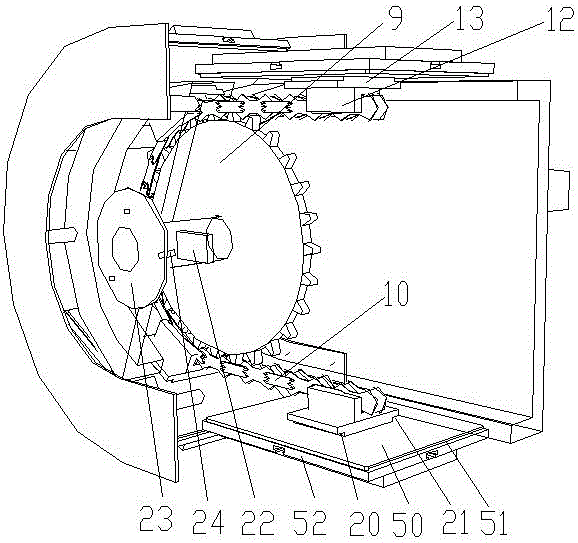

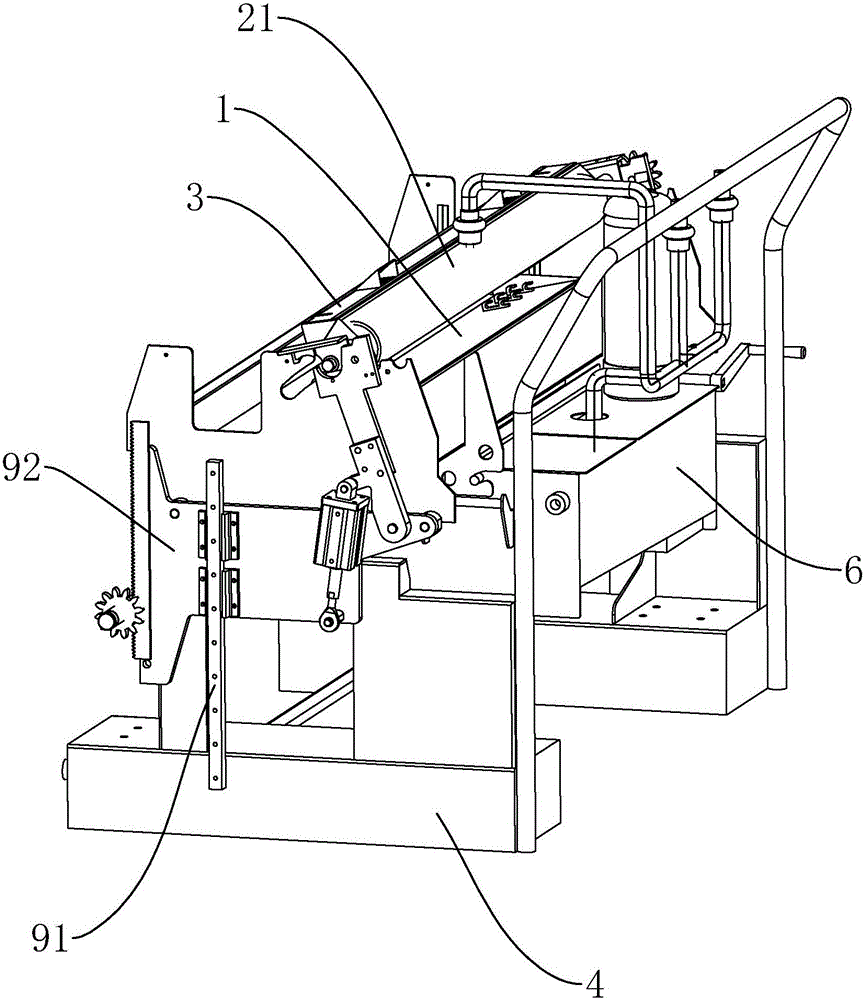

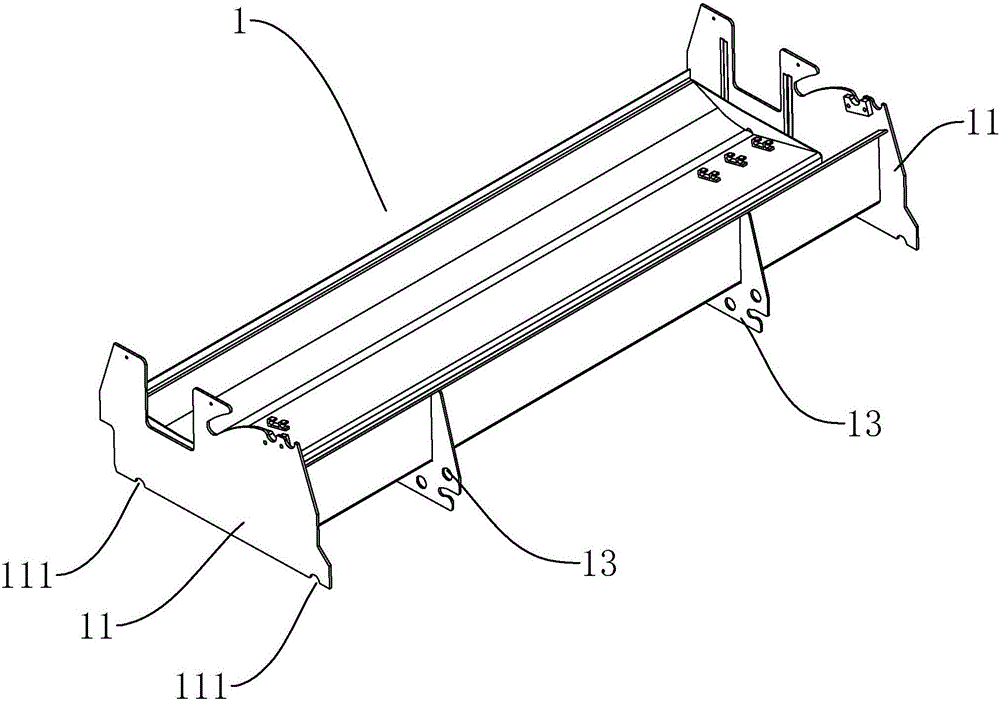

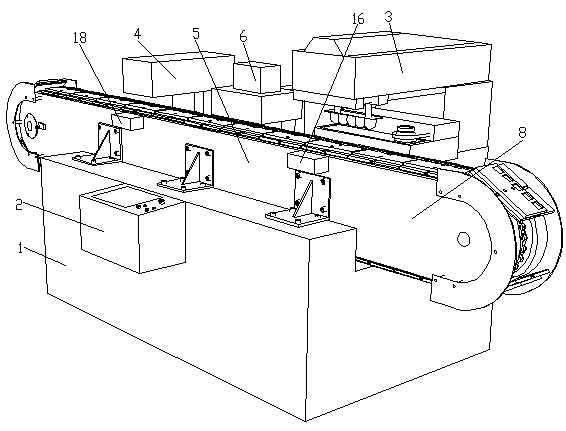

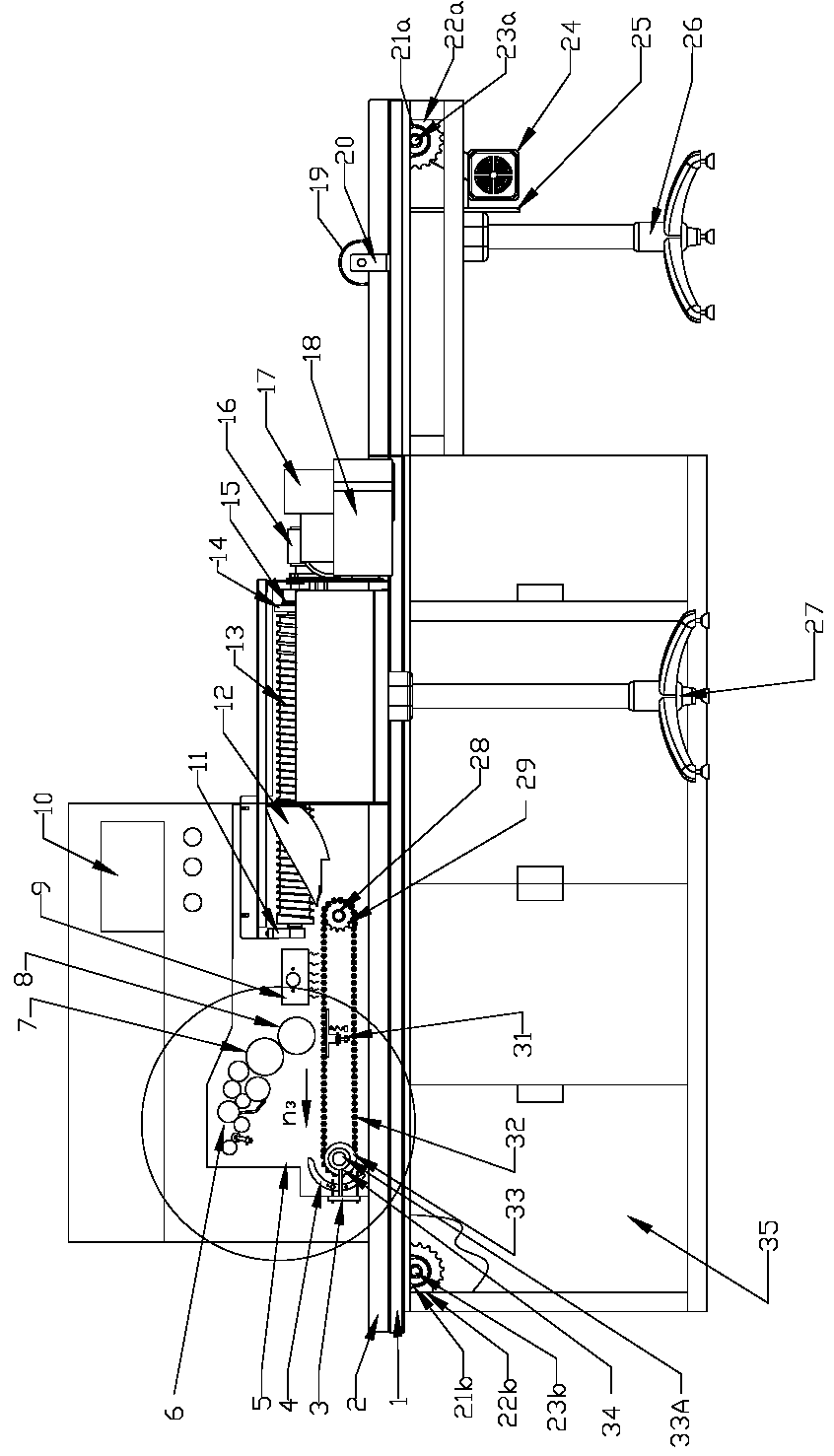

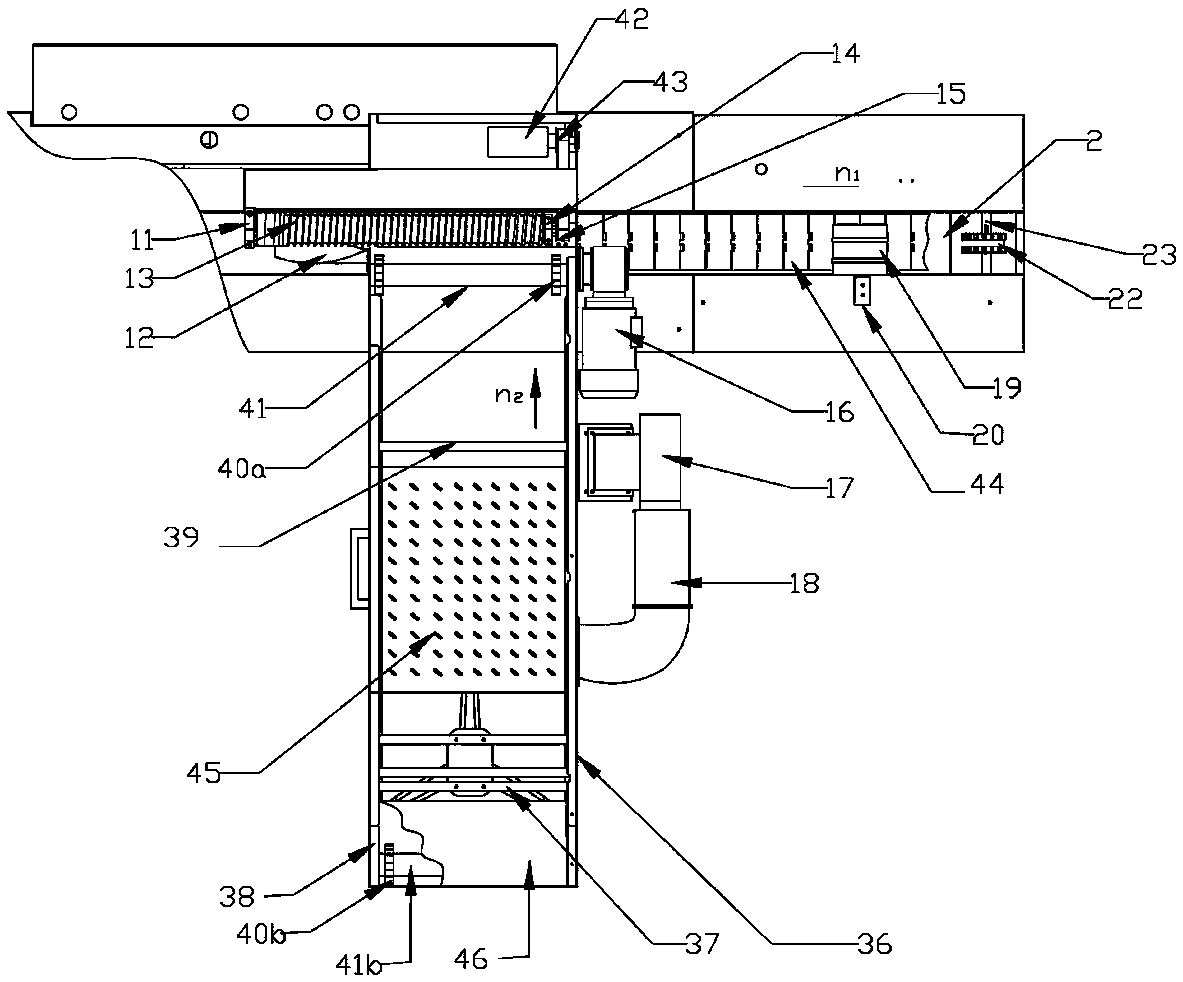

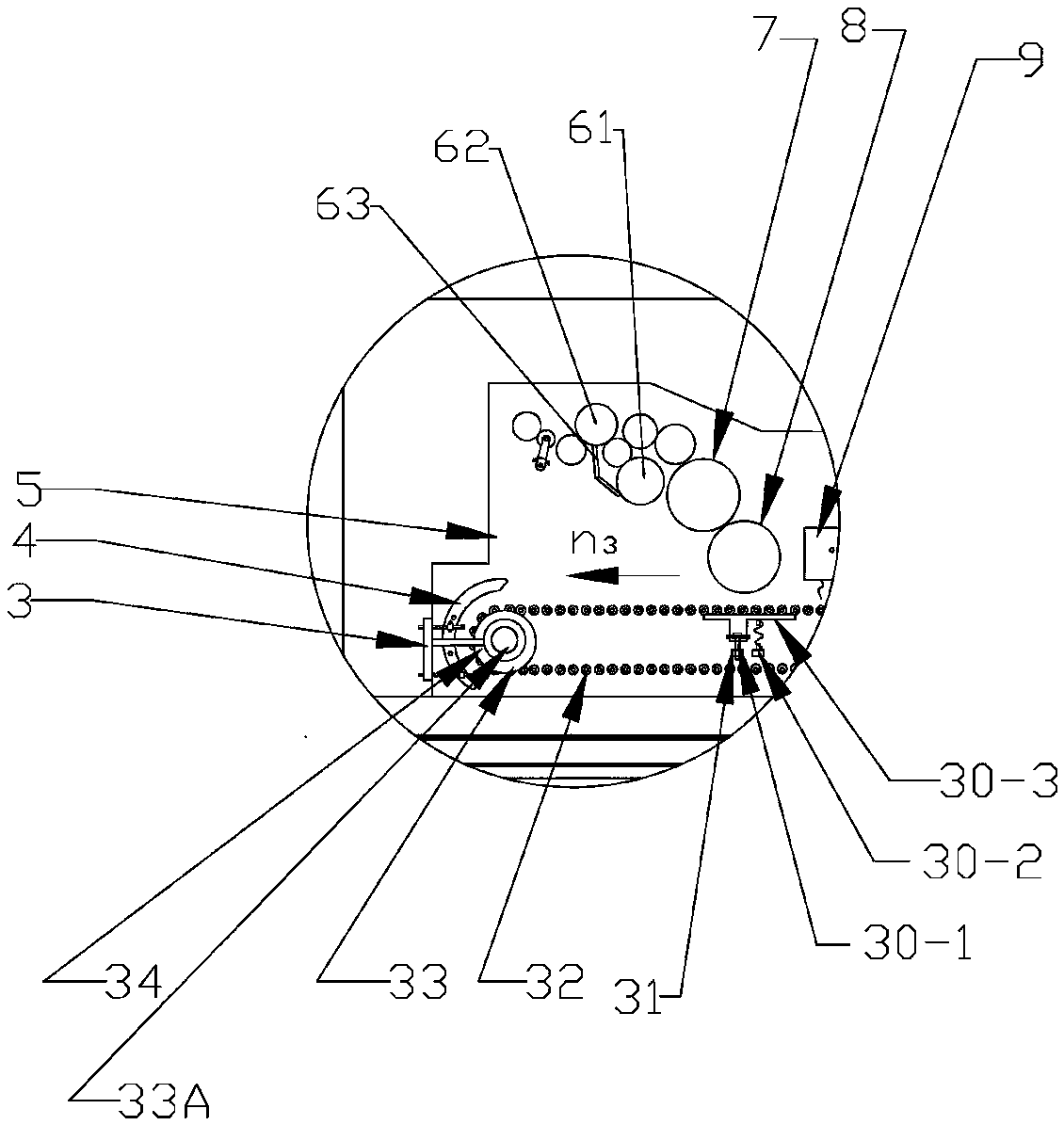

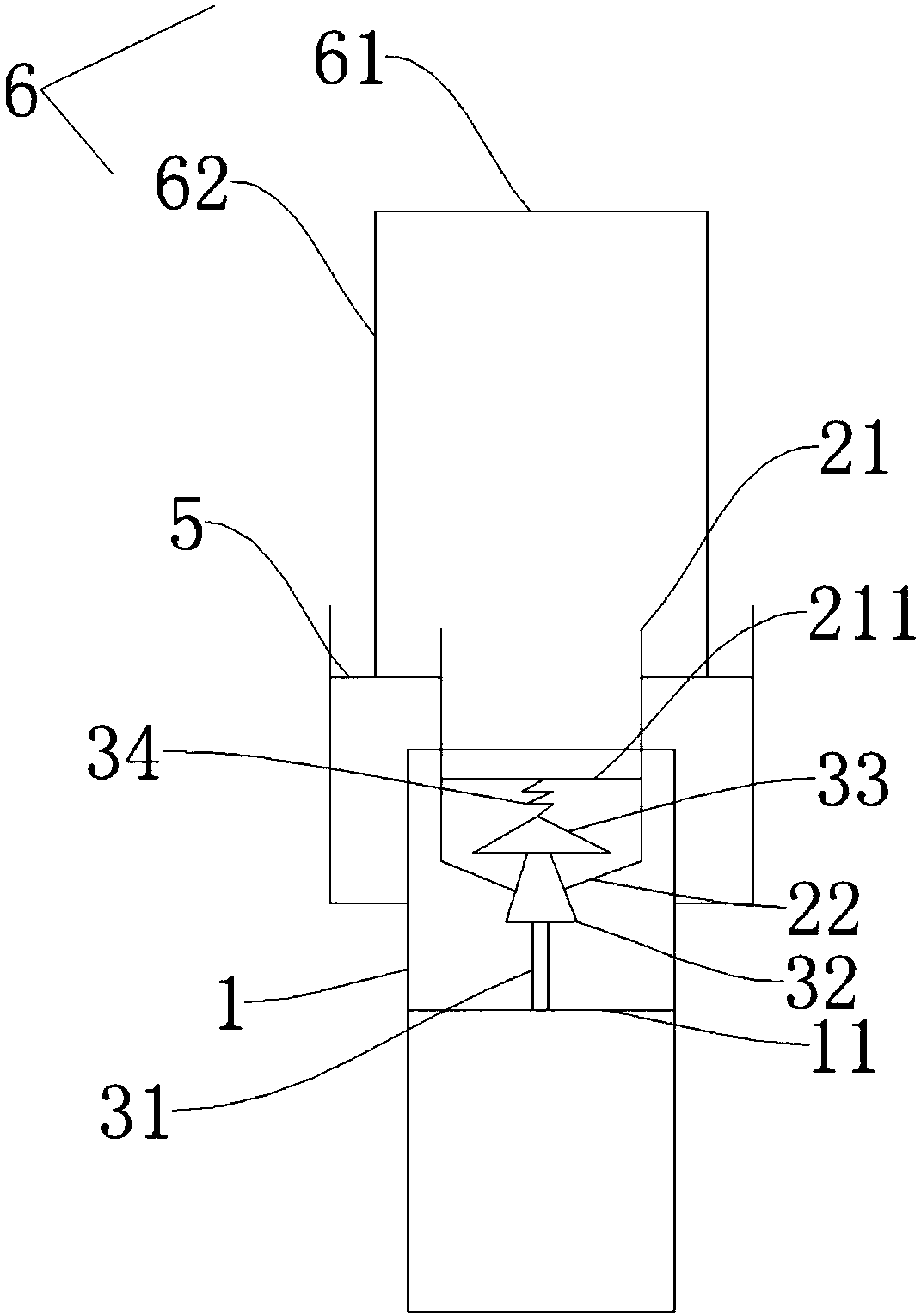

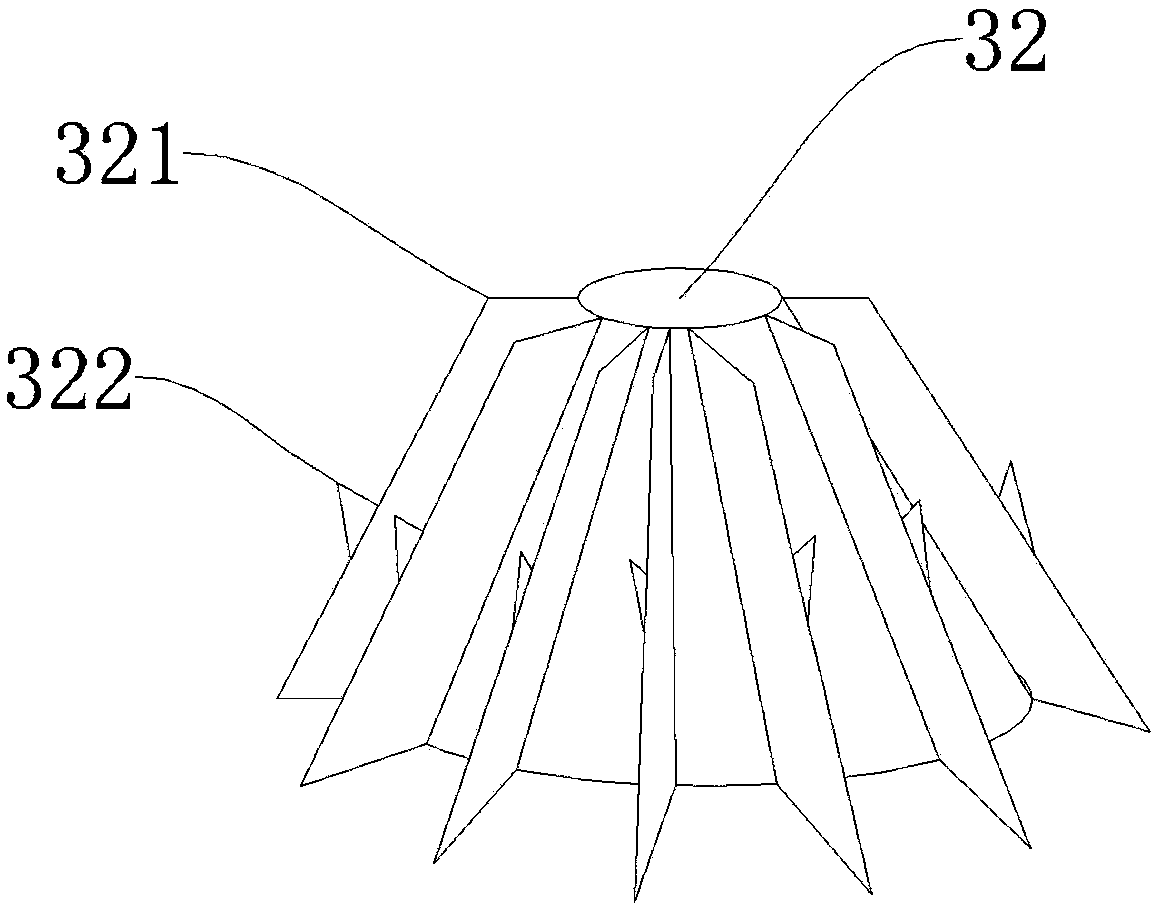

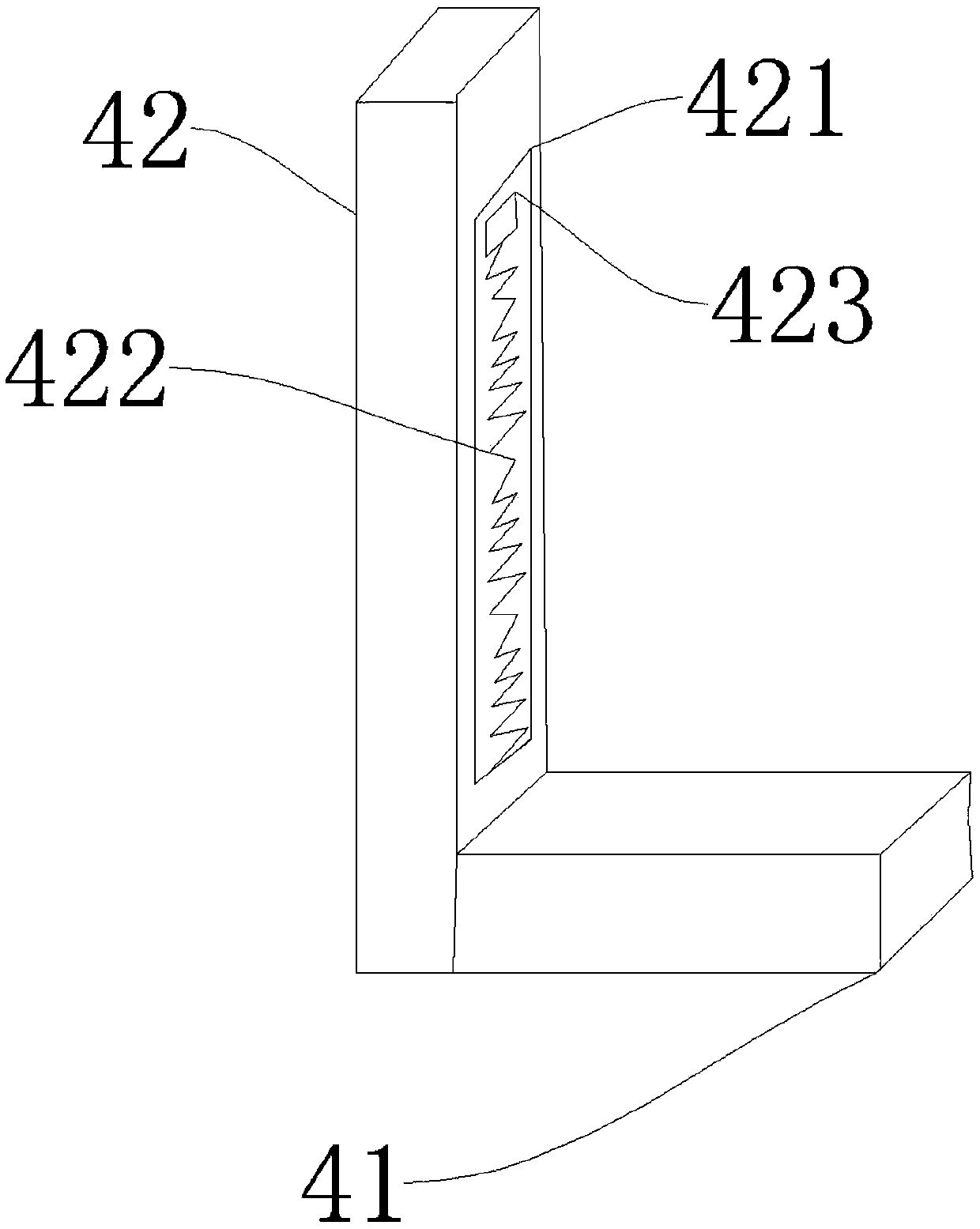

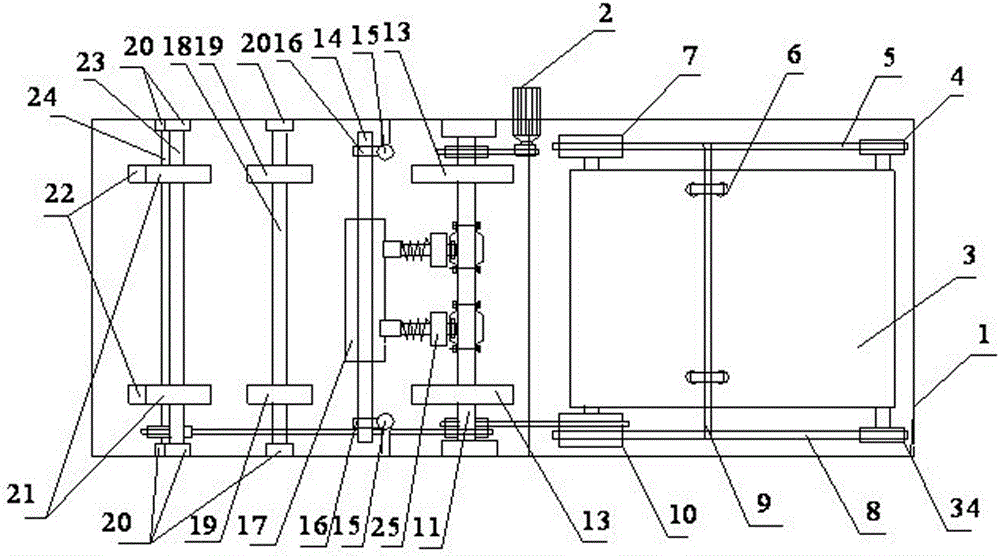

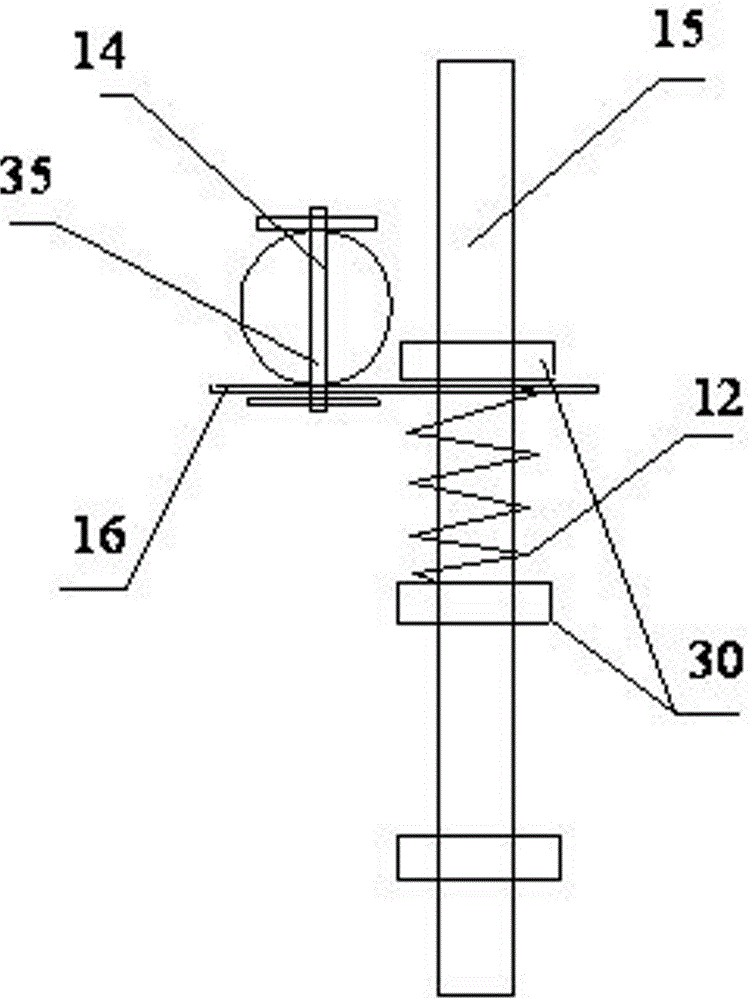

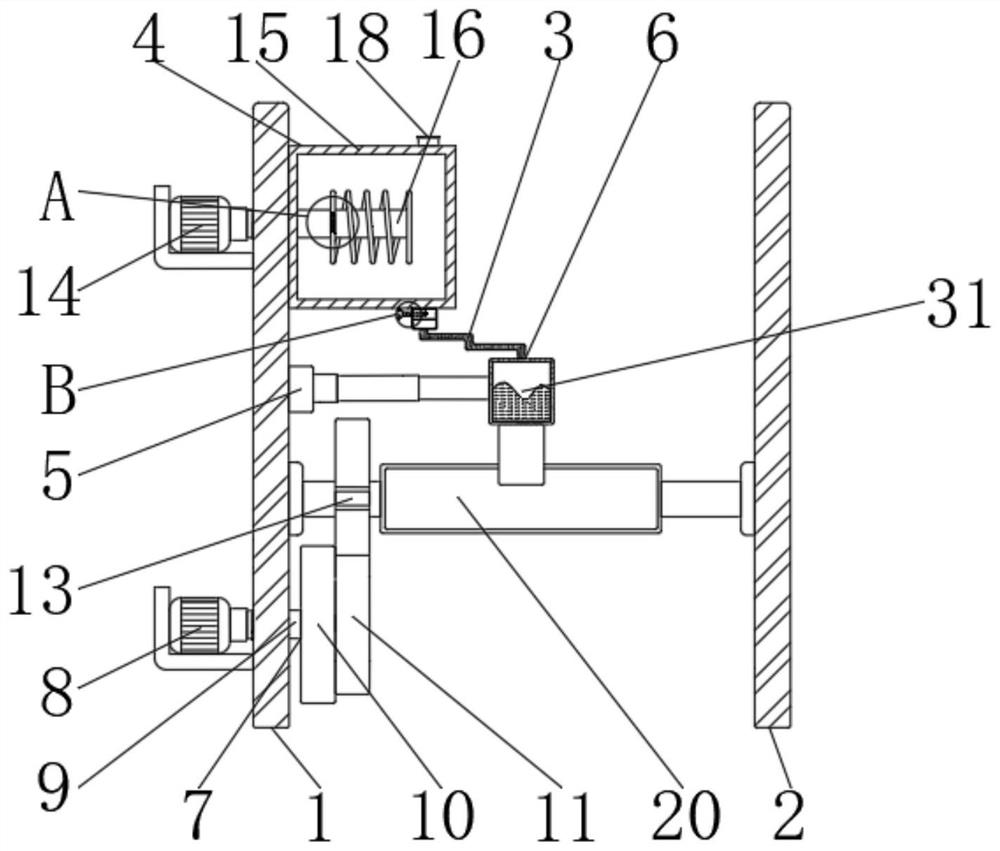

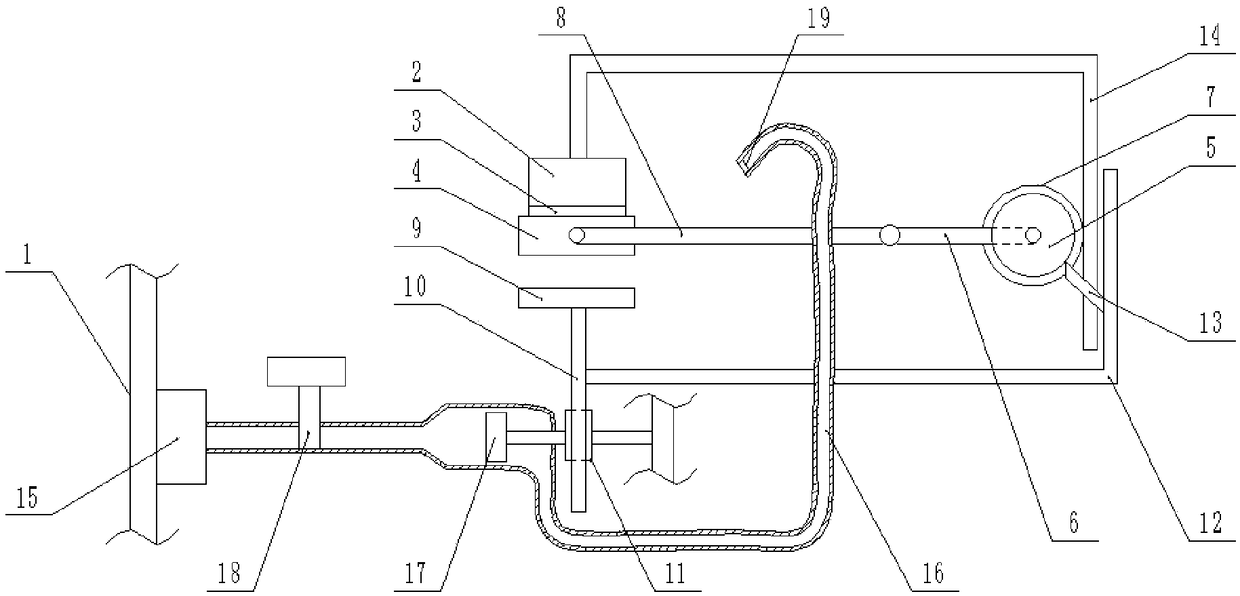

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Continuous transfer-printing coding method

ActiveCN106379042AClear outlineSqueegee steps increaseRotary pressesPrinting press partsContinuous operationLaser

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

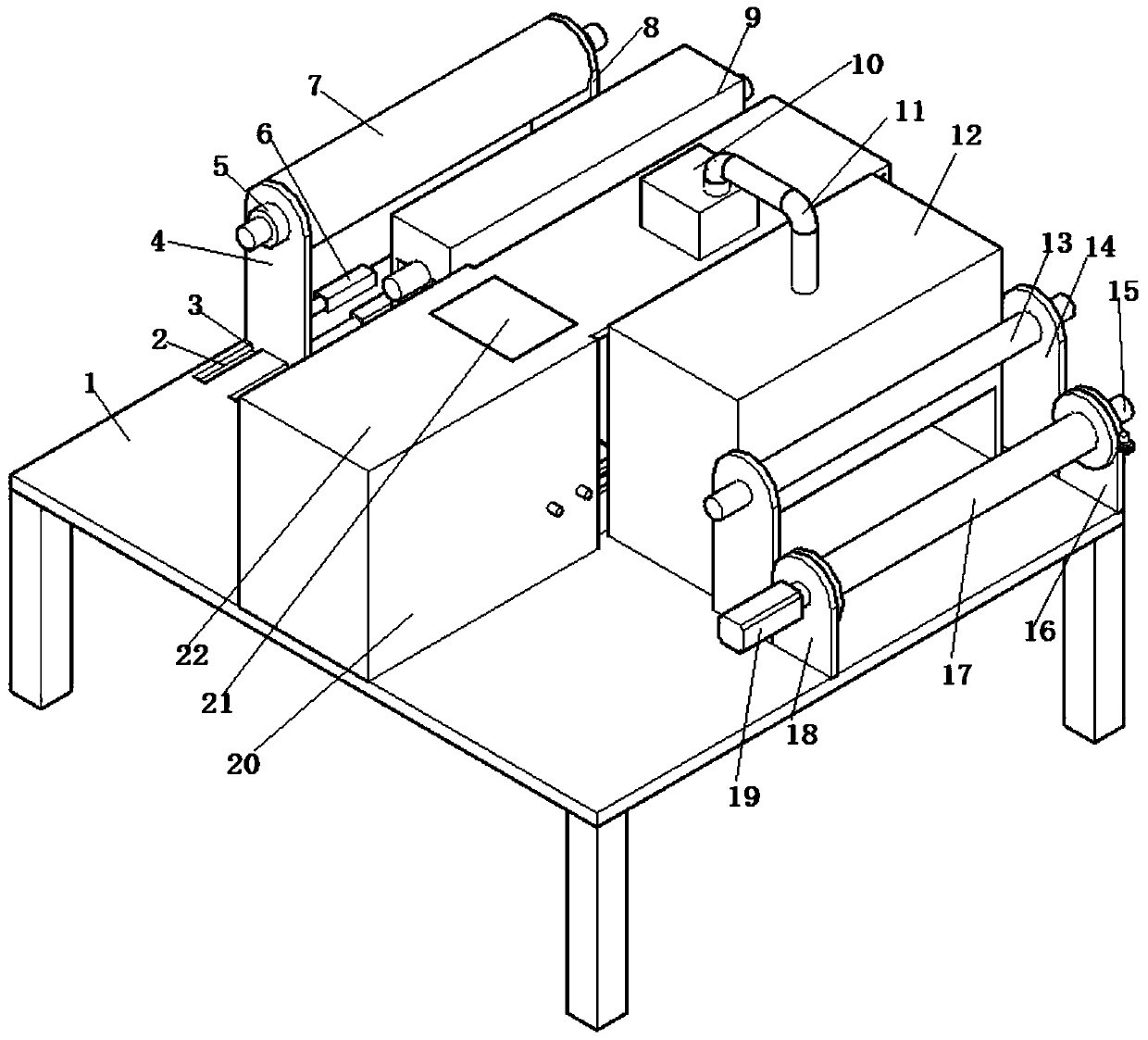

Transfer printing and coding equipment

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

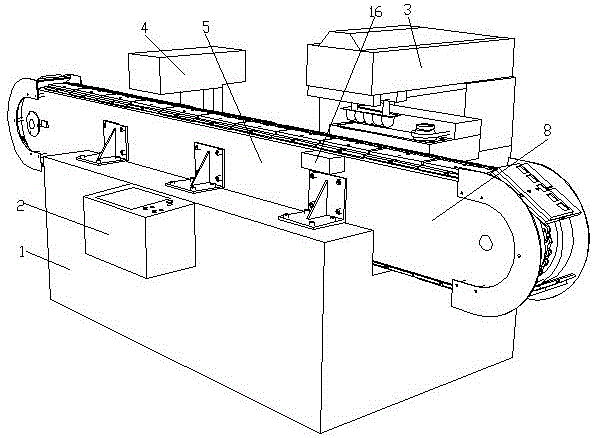

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

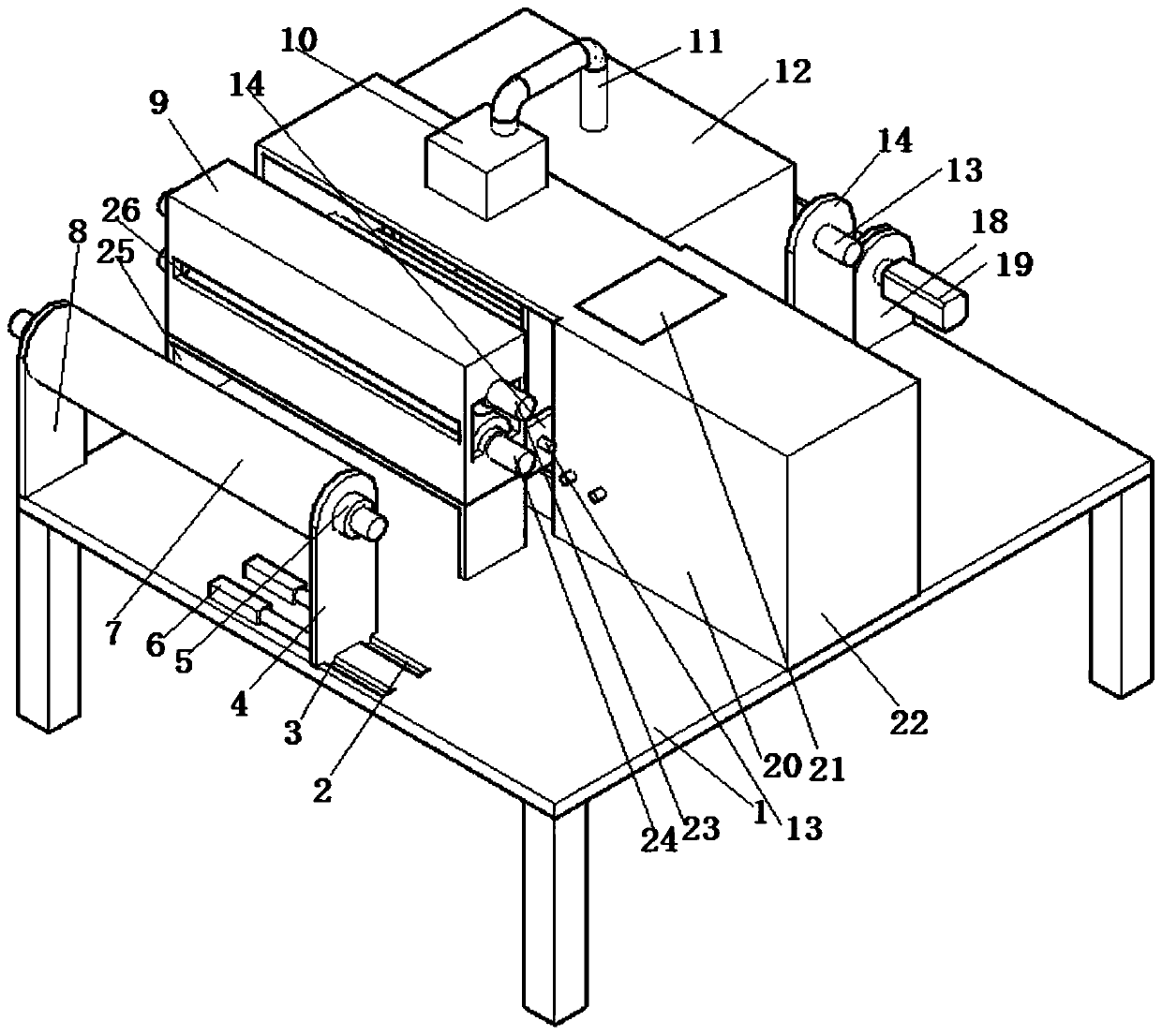

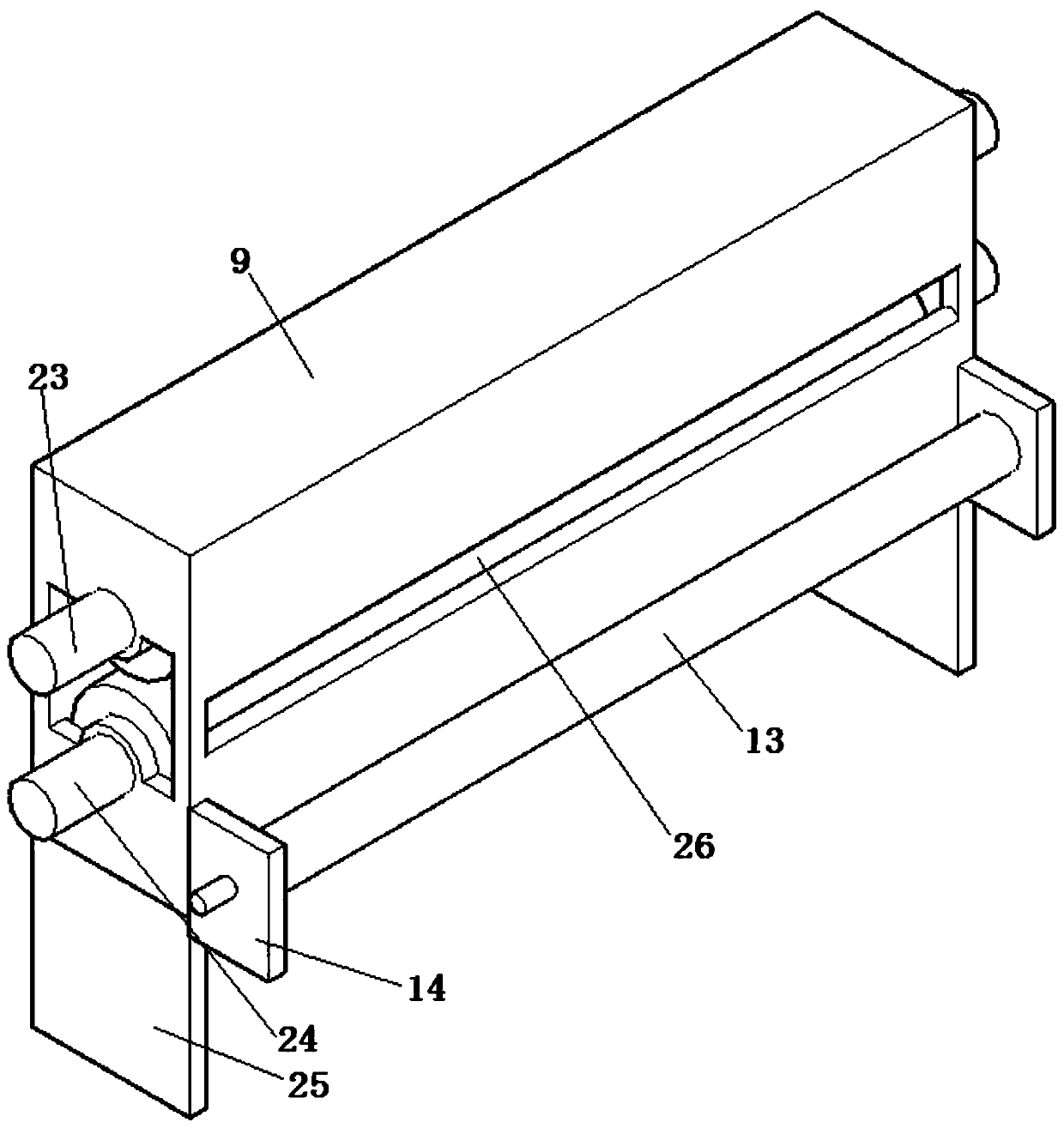

Direct type wallpaper printing equipment

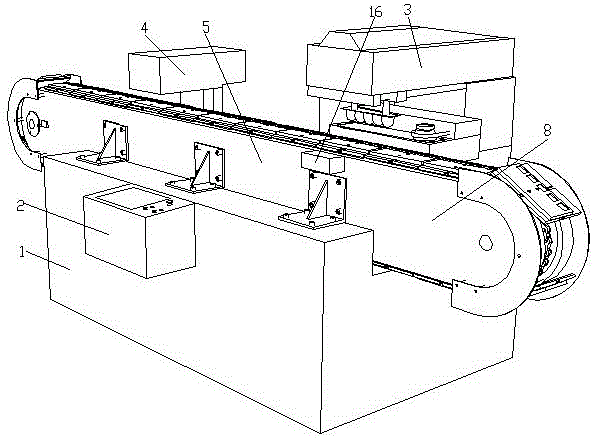

InactiveCN110626058AAvoid not completely dryInk evenlyRotary pressesPrinting press partsEngineeringPrinting ink

The invention discloses direct type wallpaper printing equipment. The direct type wallpaper printing equipment comprises a support. A printing assembly is fixedly arranged in the position, located atthe center, of the support. An unwinding assembly fixed to the support is arranged on one side of the printing assembly. A winding assembly fixed to the support is arranged on the other side of the printing assembly. A drying assembly fixed to the support is arranged between the winding assembly and the printing assembly. A flattening assembly fixed to the support is arranged between the unwindingassembly and the printing assembly. The direct type wallpaper printing equipment can flatten wallpaper base paper before printing through the flattening assembly to prevent wrinkling. Cylinders b drive a printing plate to move along sliding rails. In the ink coating process, the printing plate makes friction contact with an ink coating roll set twice to enable the surface of the printing plate tobe coated with ink evenly. The drying assembly is used for drying the printed wallpaper to prevent the phenomenon that printing ink is not absolutely dried.

Owner:六安维奥智能科技有限公司

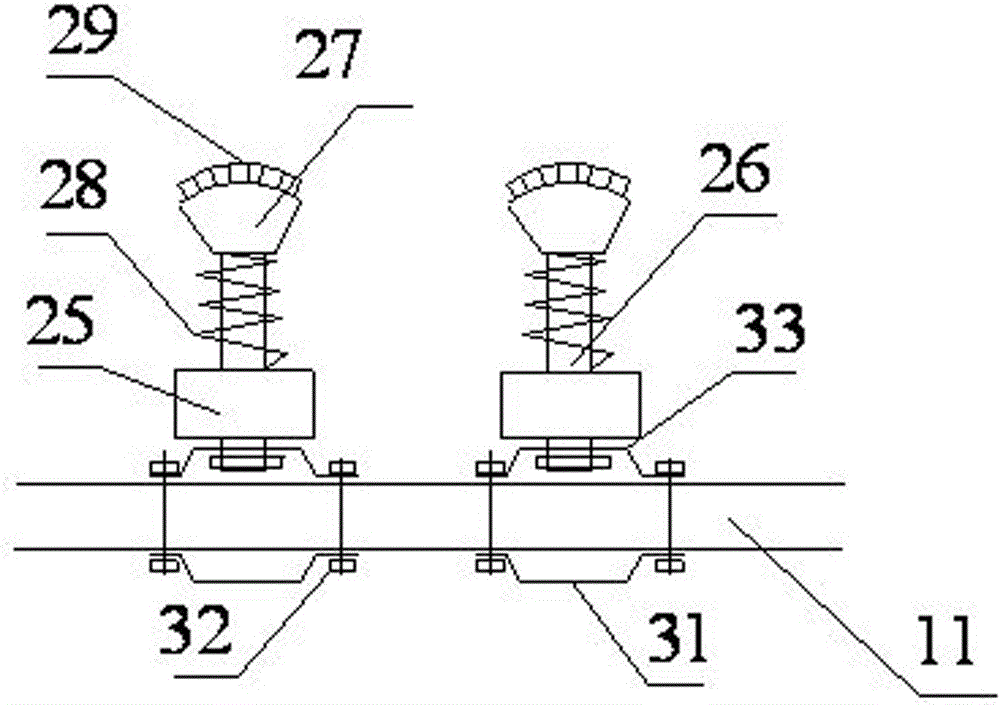

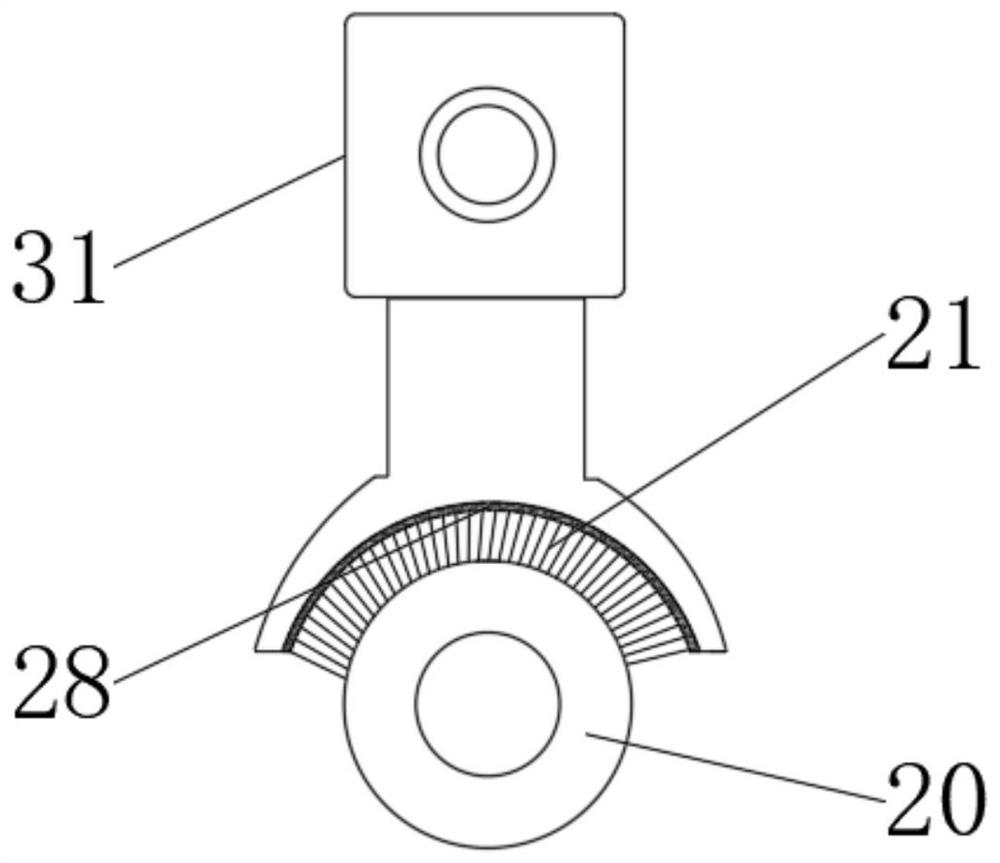

Quick double-faced date and batch number printer

The invention discloses a quick double-faced date and batch number printer which comprises a rack, a feeding part, printing parts, a discharging part and a motor. The printing parts comprise the upper printing part and the lower printing part which are of the same structure, the upper printing part comprises an upper lettering rotating shaft and an upper printing ink fixing shaft which is mounted on one side of the upper lettering rotating shaft, and the upper lettering rotating shaft is provided with a box walking wheel and a lettering assembly. The lettering assembly comprises a rubber letter nail, a letter nail clamping seat, a fixing shaft and a bearing, the bearing is detachably fixed on the lettering rotating shaft, the fixing shaft is provided with a buffer spring, one end of the fixing shaft is fixed on the bearing, the letter nail clamping seat is fixed at the other end of the fixing shaft, and the rubber letter nail is mounted on the letter nail clamping seat. The motor is in transmission connection with the printing parts, the feeding part and the discharging part. According to the quick double-faced date and batch number printer, batch numbers and dates can be printed on the upper face and the lower face of a packaging box at the same time in a printing ink stamped mode, the printing accuracy is high, the speed is high, and the effect is good.

Owner:QINGDAO JINGSHENG COLD FRESH FOOD CO LTD

Manufacturing method of stereo antifalse pulling wire

The making process of stereo anti-fake line mark includes the following steps: 1. double-sided corona treatment of the film material; 2. intaglio printing with stereo ink to form anti-fake text and pattern on one side of the film; 3. painting antistick isolator on the anti-fake text and pattern and painting acrylate contact adhesive for adhering to the carrier in the opposite side; 4. cutting the film into required sizes; 5. winding; and 6. packing. The present invention has the outstanding advantages of obvious stereo anti-fake effect, great adhesion of ink on the film, complicated making process and high anti-fake effect.

Owner:广州咏顺包装材料有限公司

Transfer-printing coding method

ActiveCN106394049ARealize continuous operationIncrease productivityDuplicating/marking methodsContinuous operationLaser

The invention discloses a transfer-printing coding method. The transfer-printing coding method comprises the following steps: (a) an ink feeding step, namely feeding ink to an etching plate by using a sealed type oil cup of a transfer-printing coding device; (b) an ink staining step, namely forwards pushing a rubber head of a transfer printer to a position above the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and pressing the rubber head downwards to be stained with the ink having patterns; (c) a transfer printing step, namely backwards pushing the rubber head to a position above a supporting plate of a conveying component, and then driving the rubber head to be pressed downwards, wherein the rubber is capable of printing the ink having patterns on a to-be-printed object in a mold groove; (d) a coding step, moving the transfer-printed object to a position below a laser coding machine, and performing laser coding by using the laser coding machine. According to the transfer-printing coding method disclosed by the invention, the laser coding machine is capable of coding the last transfer-printed object during transfer printing of a to-be-printed object of the next period, so continuous operation on large-batch to-be-printed objects can be realized, the production efficiency is greatly improved, and a coded product is high in fineness.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Manufacture method of writing brush

The invention belongs to the field of writing brush processing, and in particular relates to a production method of a writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) washing rabbit hair, duck hair and pig hair with soap respectively Soak in water for 50-75 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; 3) Use the treated rabbit hair, duck hair, pig hair and modified nylon hair The combing machine mixes evenly in proportion, and picks a bunch of the mixed pen core hair when making the pen core, spreads the bunch of hair on a flat plate, after grooming, and then rolls up from one end to form a conical pen tip. Put the tied nib on the pen tube and connect it with glue. Through the improved nylon hair technology, this brush is more elastic, more durable, and has a long storage time; coupled with the elasticity of animal hair itself, this brush is vigorous and powerful in use, soft and hard, and suitable for a wide range of people.

Owner:广安市广安区长乐小学校

Ink applying device capable of preventing ink misting

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

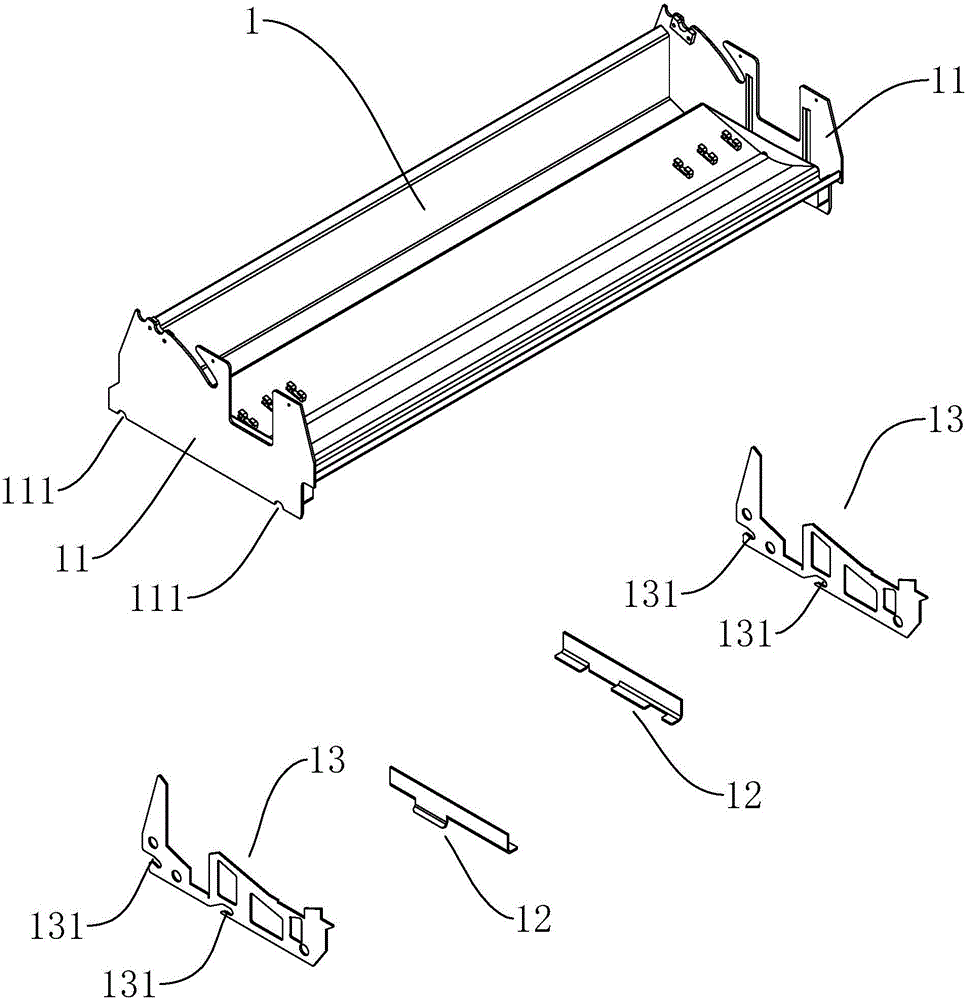

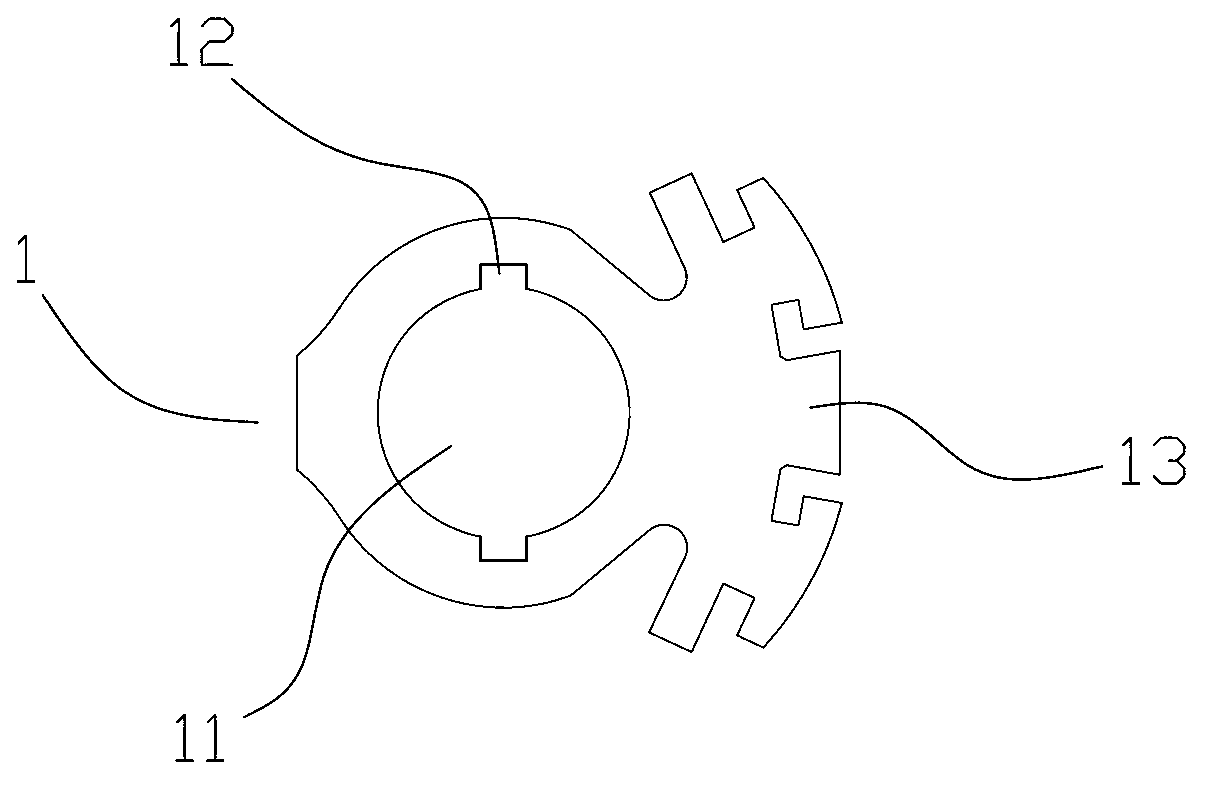

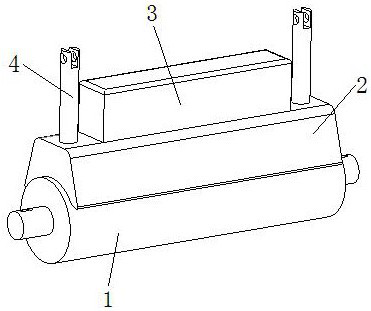

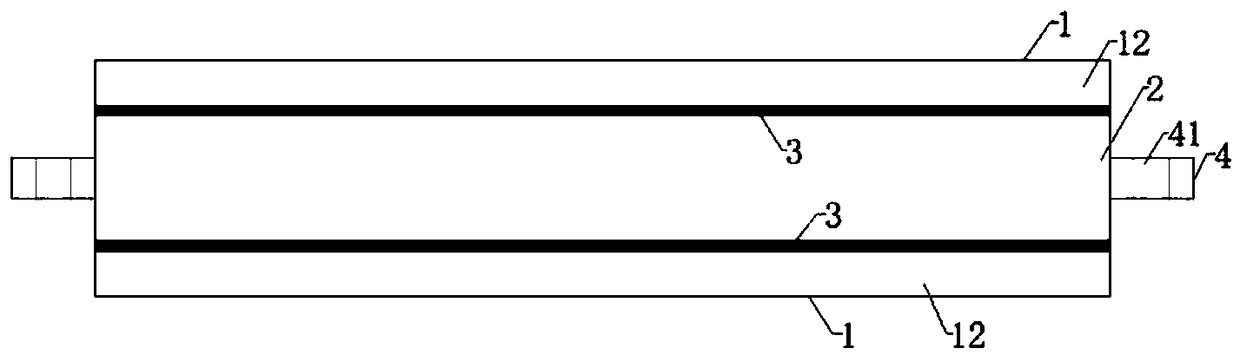

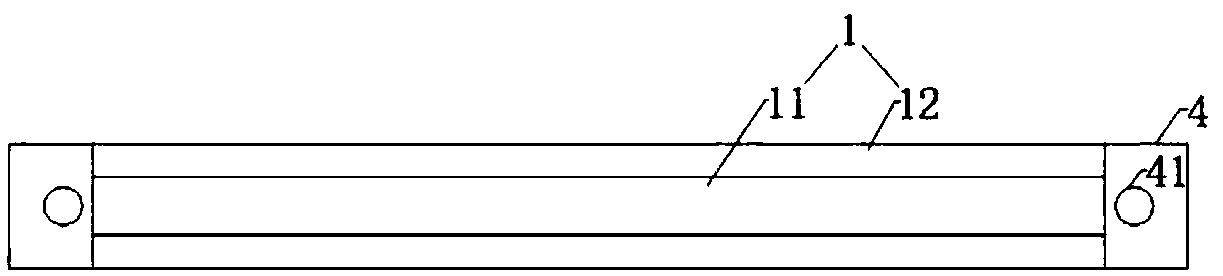

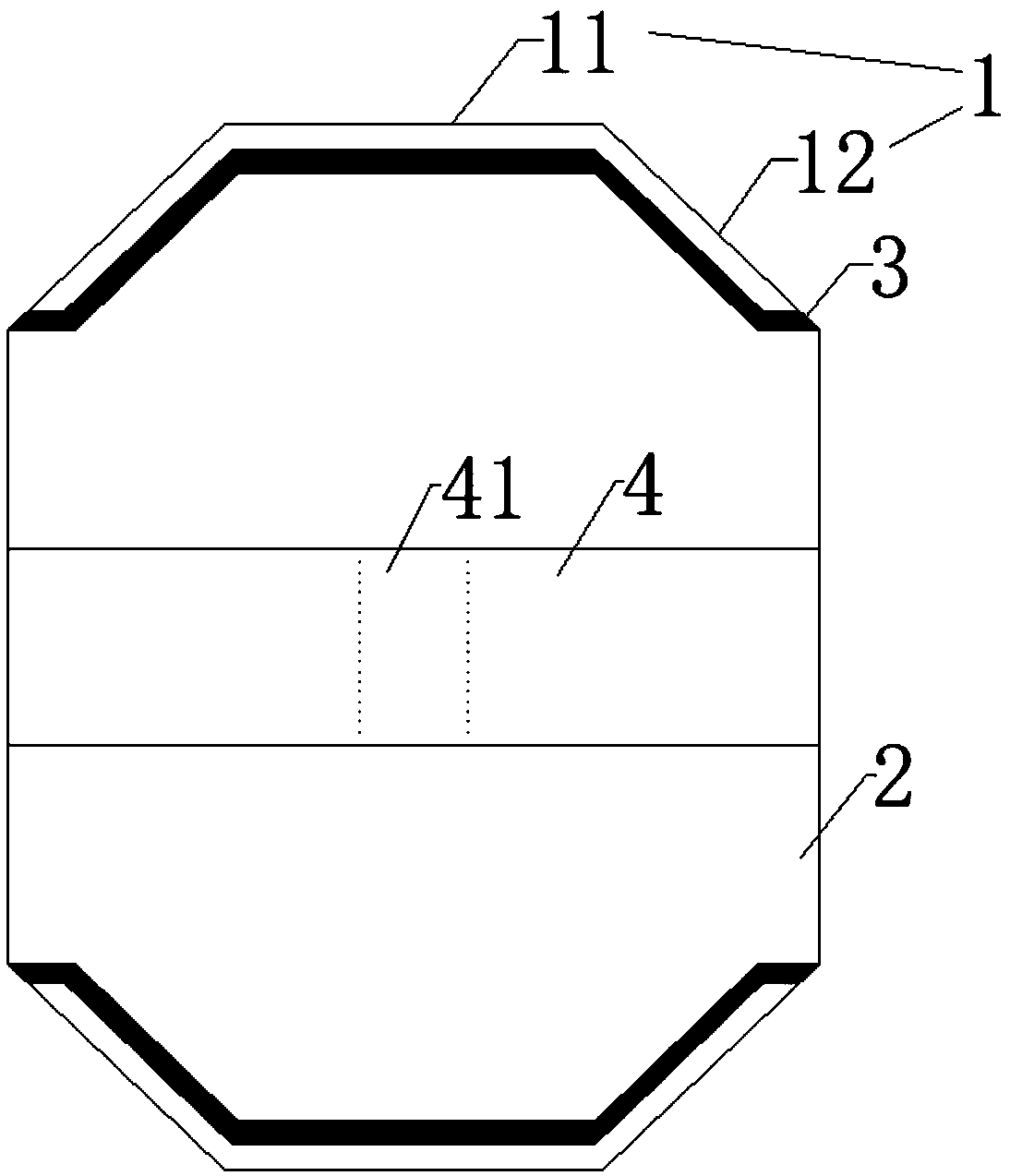

Plane surface printing roller of needle printer

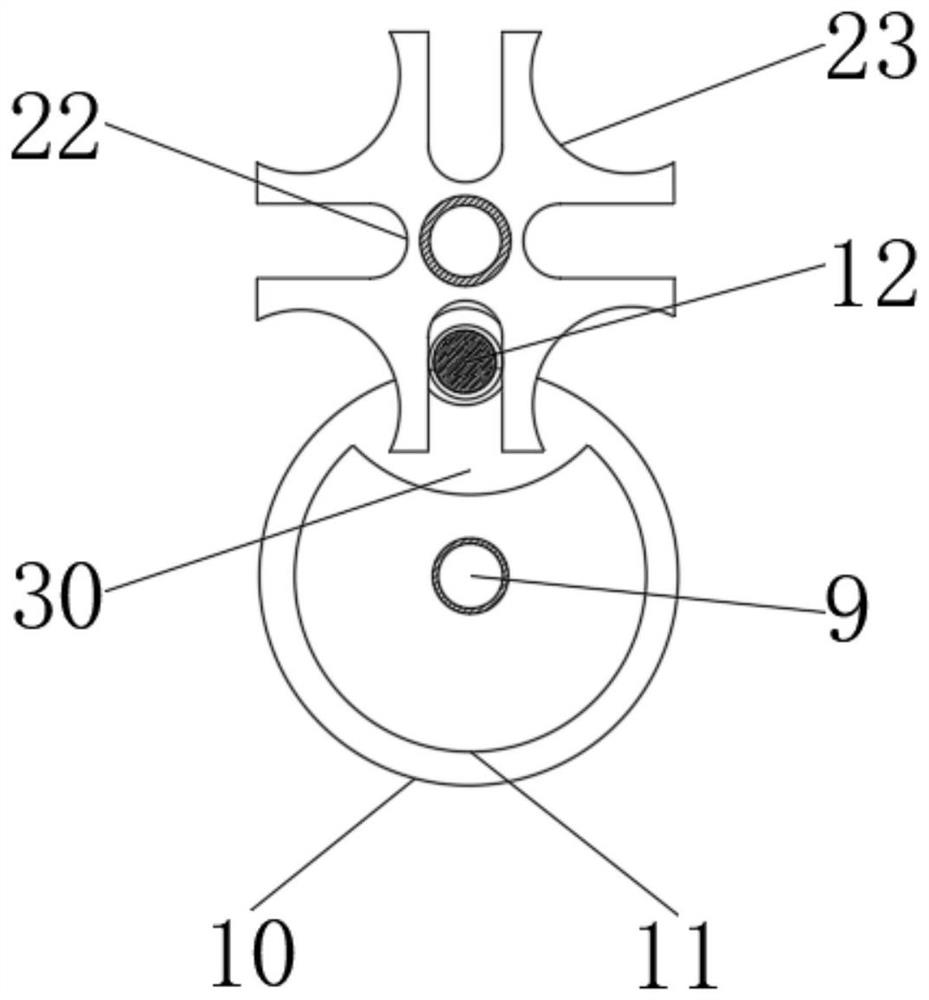

ActiveCN102991146AEasy to locate and installAccurate installation and positioningOther printing apparatusNeck partsEngineering

The invention discloses a plane surface printing roller of a needle printer, which comprises a bracket, wherein both ends of the bracket along the length direction are connected with a support shaft for mounting and fixing the bracket on the fame of the printer, and an irregular mounting surface is arranged at the tail end of the support shaft; the top of the bracket is provided with a neck part; a flexible glue layer is injected on the neck body; the middle surface of the flexible glue layer is a horizontal surface, and both side surfaces of the flexible glue layer are inclined surfaces. The plane surface printing roller and the frame are convenient and accurate to install and locate; the flexible glue layer is not easy to drop off from the bracket, and the middle surface is the horizontal surface, so that the distances between printing work surfaces and a printing head are the same, the uniformity of ink printed on paper by the printing head is ensured, and the printing quality is improved; moreover, relatively thin thickness of the flexible glue layer can be ensured through the structure, so that only few changes of the printer in a gap between the printing work surfaces and the printing head in a specified temperature range are ensured, and the printing quality under extreme temperature condition can be efficiently improved.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

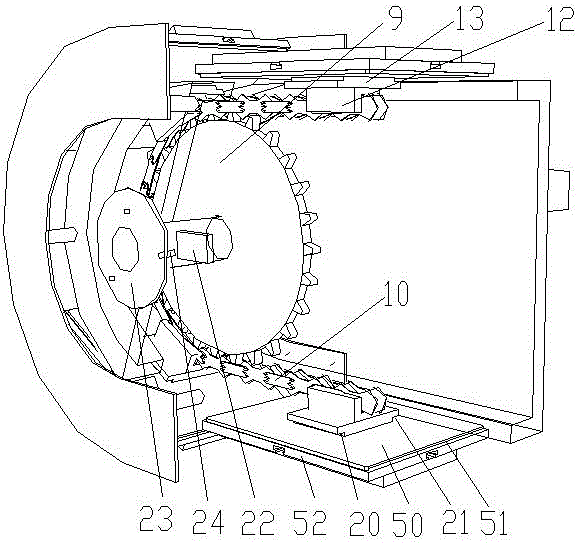

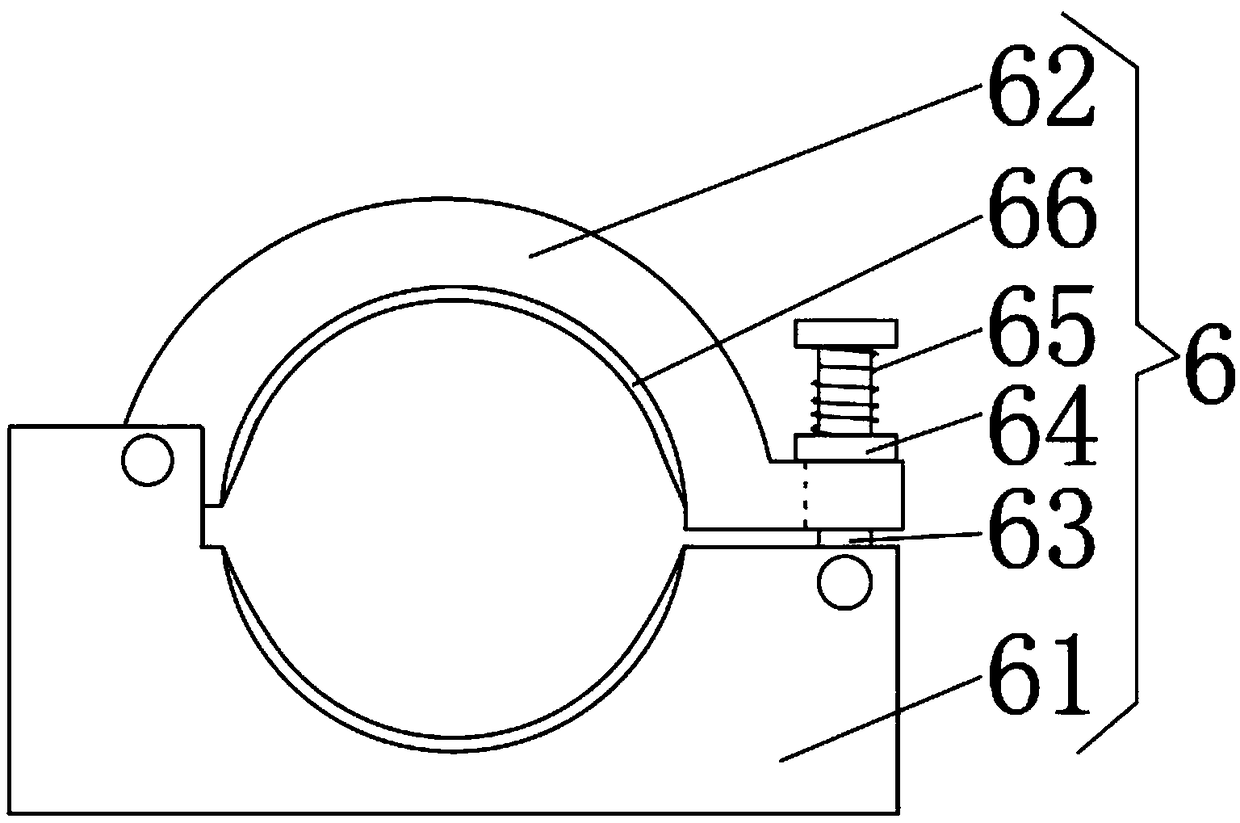

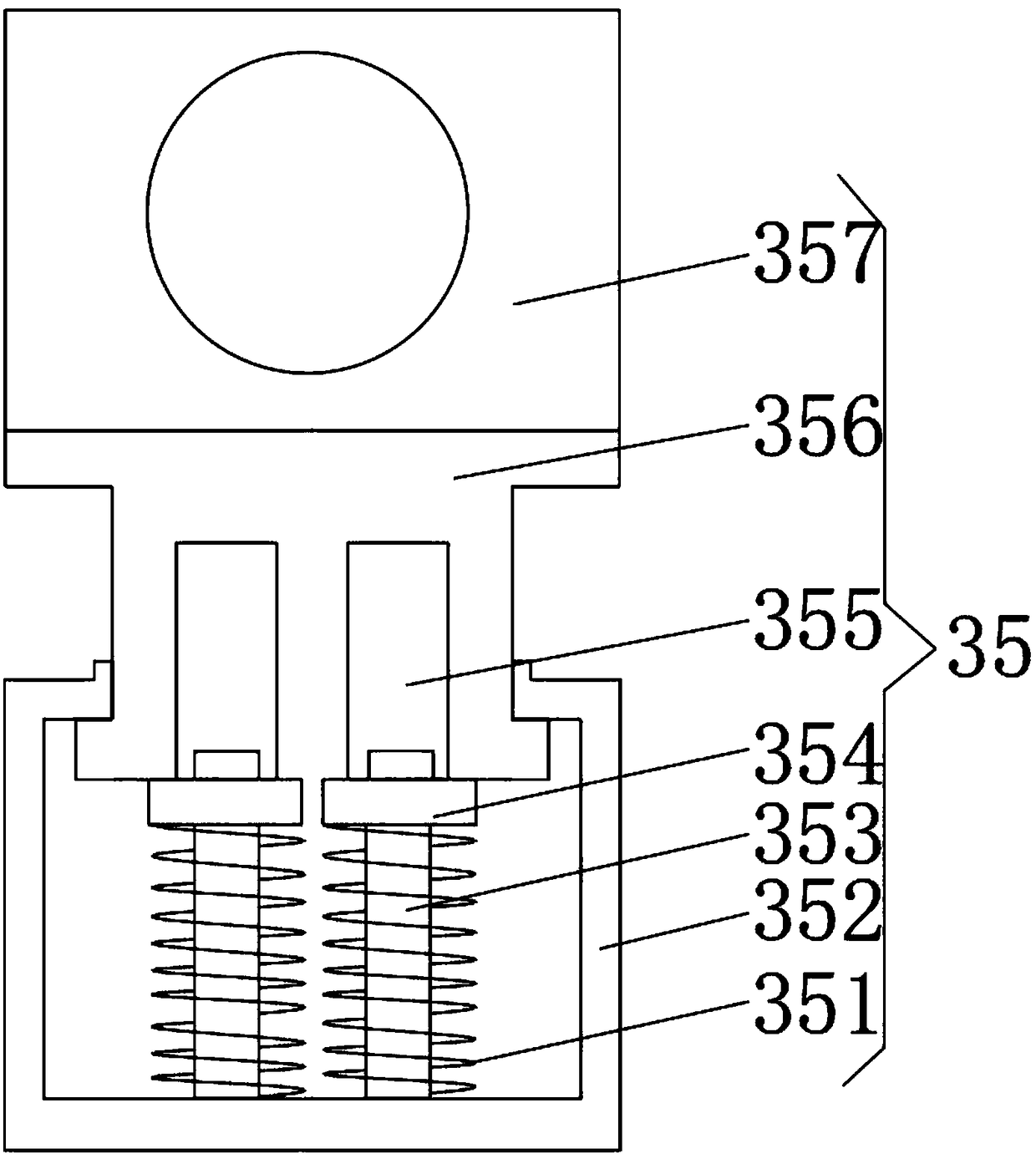

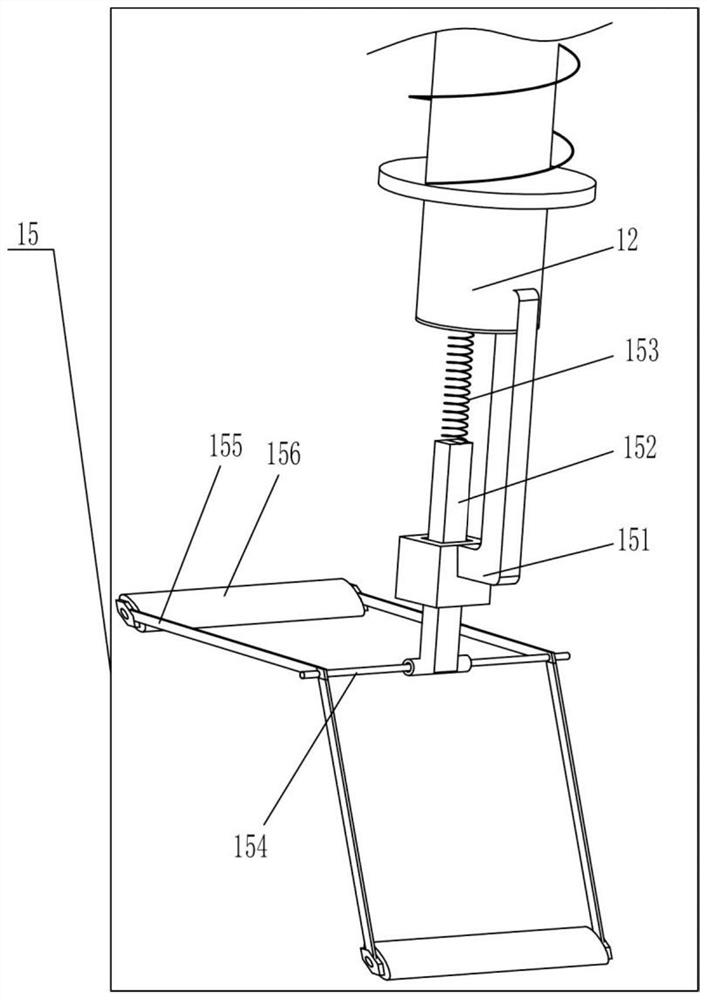

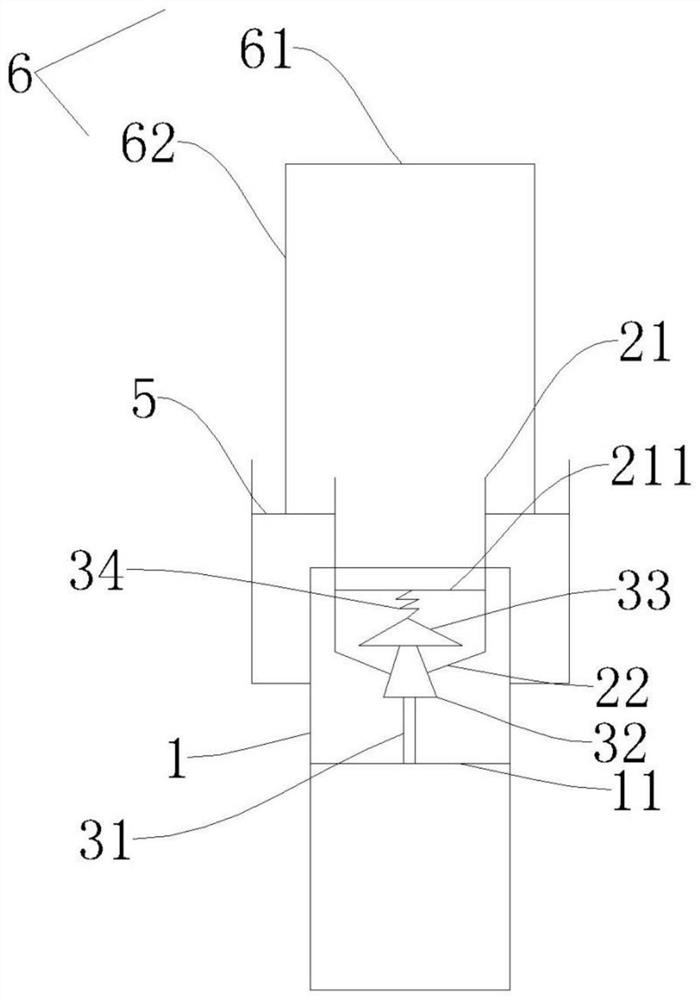

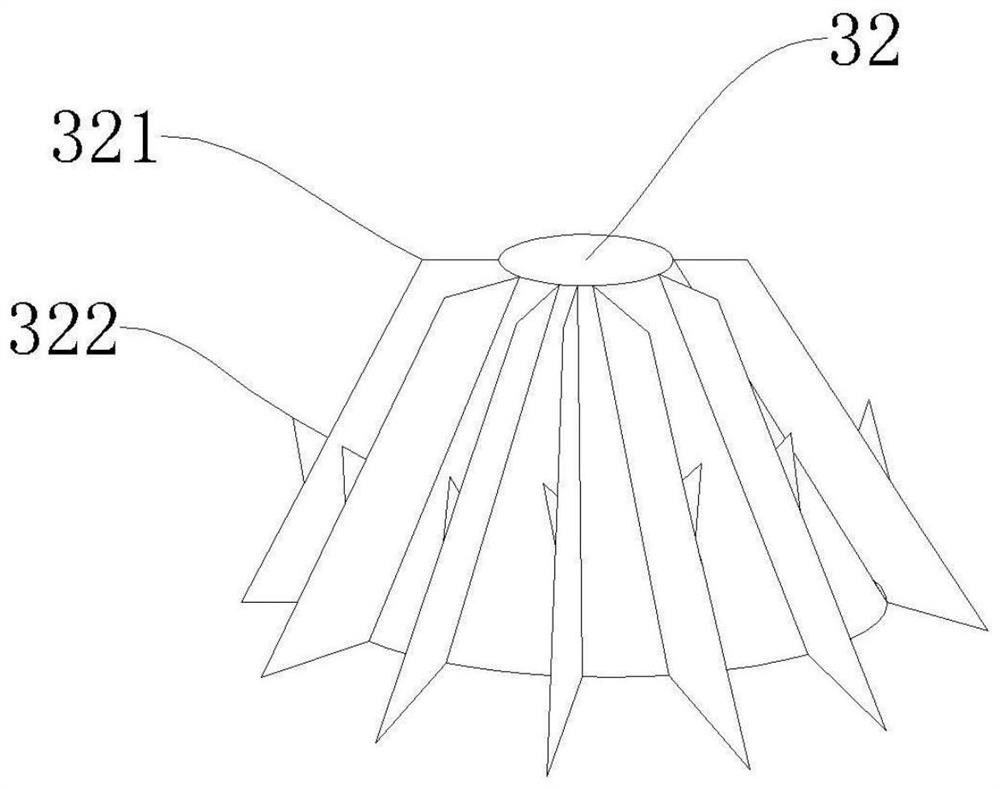

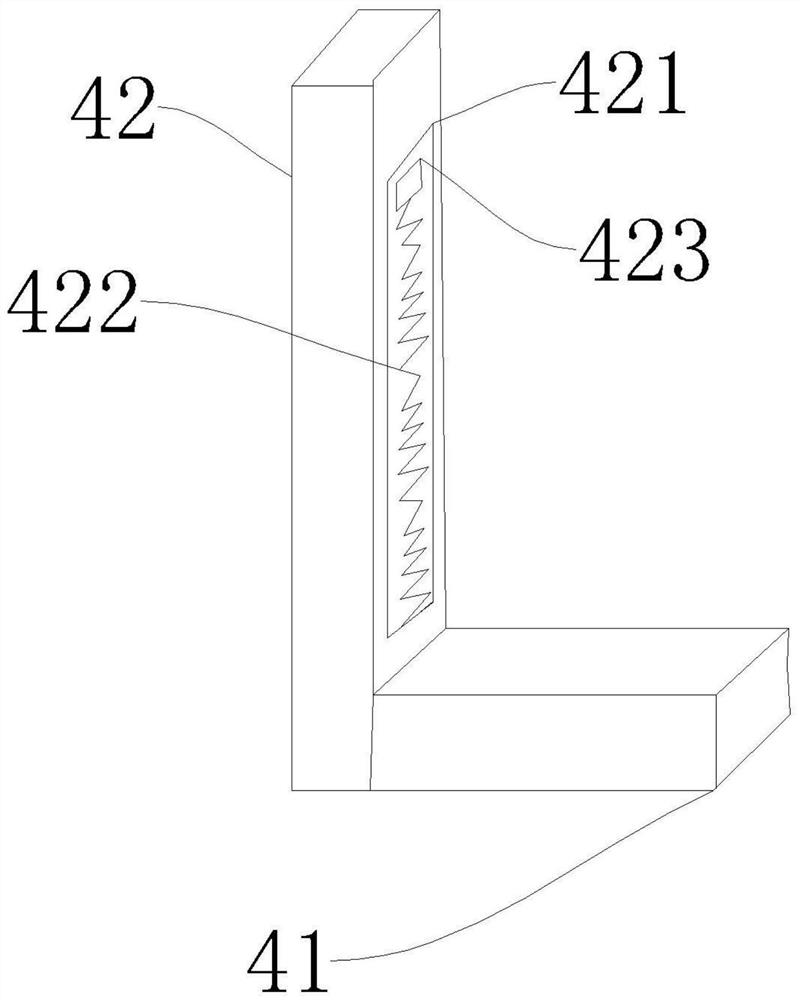

A continuous pad printing coding equipment

ActiveCN106364152BPad printing stabilityPad printing precisionRotary pressesPrinting press partsElectricityPad printing

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

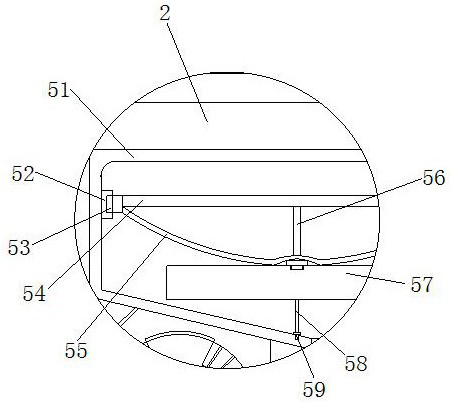

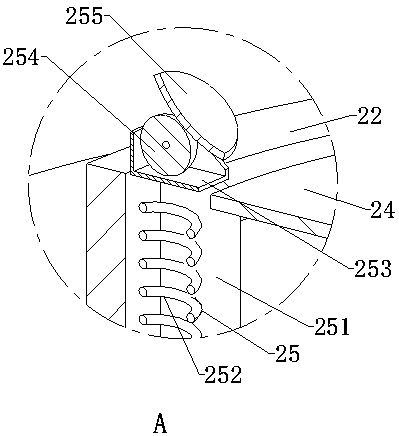

Inking device of colored tape

InactiveCN108569051AQuality improvementSolve the problem of not evenly invading the tape baseInk ribbonsEngineeringScrew thread

The invention discloses the inking device of a colored tape. The device comprises a box body. A dye box is fixedly connected between the two opposite sides of the inner wall of the box body. A first roller and a second roller are successively and rotatably connected between the two opposite sides of the inner wall of the dye box. A third roller, a fourth roller, a first active pressing roller, a second active pressing roller, and a colored tape material collecting roller are successively and rotatably connected between the two opposite sides of the inner wall of the box body. A rotation pedestal is fixedly connected between the two opposite sides of the inner wall of the box body. A screw rod is rotatably connected between the top of the rotation pedestal and the top of the inner wall of the box body. The surface of the screw rod is connected to a moving plate in a threaded connection mode. The bottom of the moving plate is rotatably connected to a driven pressing roller through a buffer device. A rotation roller is rotatably connected between the two opposite sides of the inner wall of the box body. The device relates to the colored tape technology field. By using the inking device of the colored tape, a problem that the ink can not invade a tape base uniformly during a colored tape inking process is solved, the uniform ink in the colored tape is guaranteed and the quality ofthe colored tape is increased.

Owner:湖州富丽华色带有限公司

Manufacturing method for bamboo filament brush pen

InactiveCN107718931AStable inkingInk evenlyWood treatment detailsReed/straw treatmentAcetic acidRetention time

The invention belongs to the field of writing brush processing, and in particular relates to a method for making a bamboo silk writing brush, comprising the following steps: 1) modifying nylon hair to obtain modified nylon hair; 2) separately making rabbit hair, duck hair and pig hair Soak in soapy water for 45-60 minutes, then soak in starch solution for 20-35 minutes, take it out and soak in acetic acid for 3-5 minutes; Soak in water for 4-5 hours, take it out and steam it for 1-2 hours, take it out and make bamboo silk; 4) Mix the treated rabbit hair, duck hair, pig hair, modified nylon hair and bamboo silk in proportion with a carding machine , Pick a bundle of mixed refill hair when making a refill, spread this bundle of hair on a flat plate, after grooming, and then roll it up from one end to make a conical pen tip, and put the tied pen tip into To the pen barrel, add glue to connect. The brush made by the invention is elastic, more durable and has a long storage time.

Owner:广安市广安区长乐小学校

High-folding-resistance packaging paper

InactiveCN105064115AWide range of raw materialsMild responsePaper/cardboardChemical/chemomechanical pulpCalcium silicateFolding endurance

The invention discloses high-folding-resistance packaging paper. The high-folding-resistance packaging paper is characterized by being made from gypsum whiskers, glycerol, calcium silicate, fir powder, sodium alga acid, polypropylene and laminaria japonica which are proportioned by weight. The packaging paper has the advantages that raw material resources are wide, reaction is mild, and the packaging paper is free of poison and environment-friendly, and the modern green chemistry concept is met. By adding the gypsum whiskers and the calcium silicate during beating, the tensile strength of the paper can be improved, the strength property of the paper is improved as the pulp beating degree is increased, and the packaging paper can be inked more evenly. By adding laminaria japonica extracts, the flexibility of the paper can be improved, and the strength property of paper sheets made in this way can be improved remarkably.

Owner:HEFEI LONGFA PACKING CO LTD

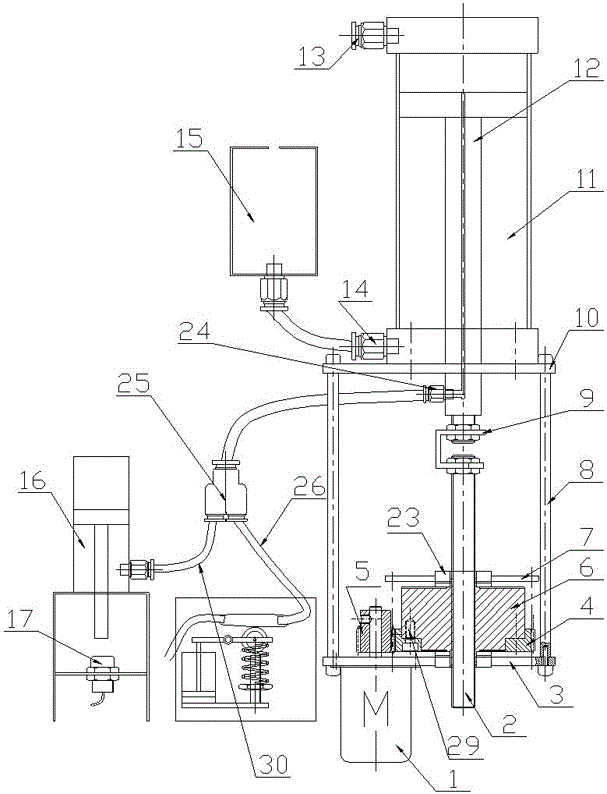

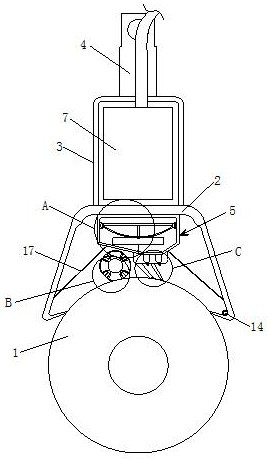

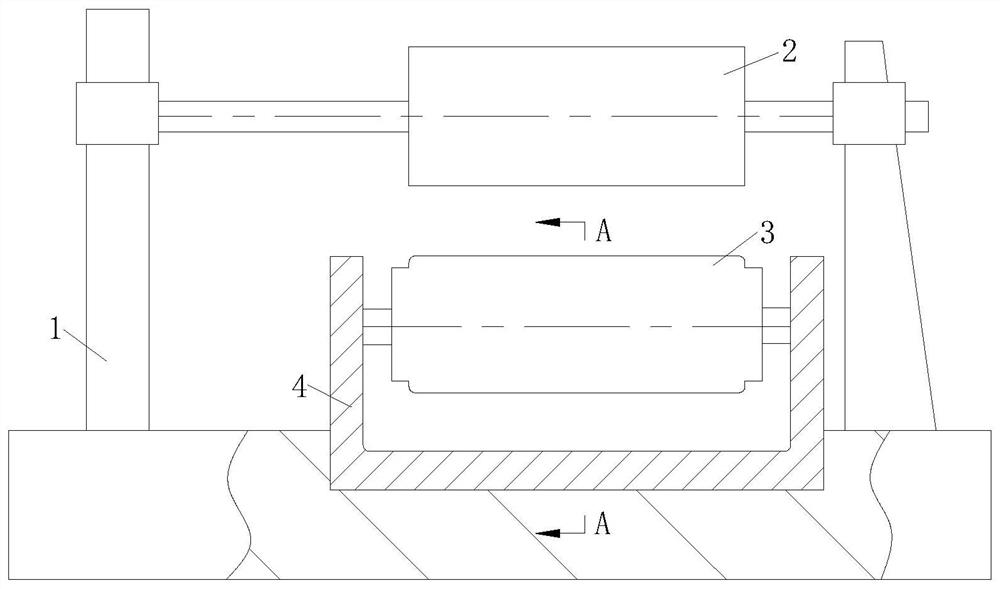

A high-definition printing machine for small-capacity injection ampoules in pharmaceutical factories

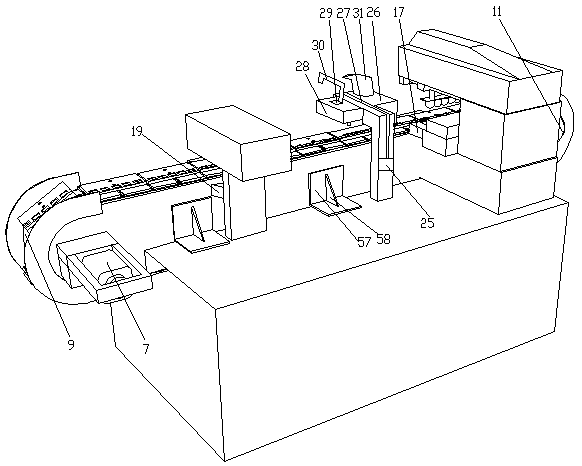

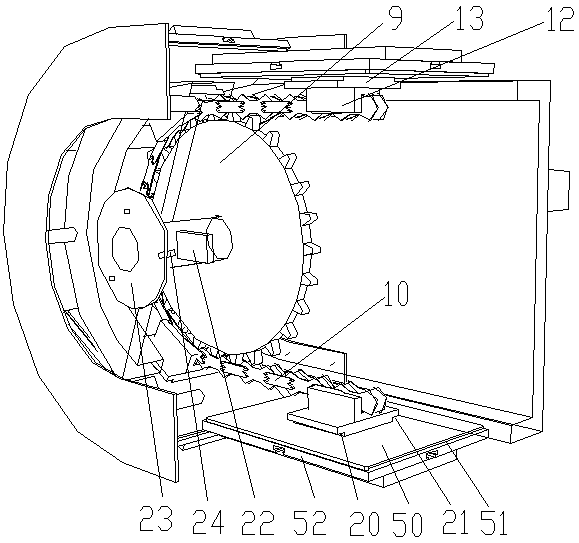

ActiveCN105922730BPrint clearPrinting efficiencyRotary pressesOther printing apparatusPrinting inkEngineering

The invention relates to an ampoule bottle printer and particularly relates to a high-definition printer for a small-volume injection ampoule bottle of a pharmaceutical factory. The printer comprises a frame, and an ampoule bottle printing device, an ampoule bottle horizontal loading device and a box bracket conveying device arranged on the frame; the ampoule bottle printing device comprises two printer wall boards which are vertically arranged on the frame and are parallel to each other, wherein an ink storage box, a glass printing ink transmission mechanism, a letter roller and a rubber blanket roller are arranged between the two printer wall boards; the ampoule bottle horizontal loading device comprises conveyer belt wall boards arranged on the frame, an ampoule bottle conveyer belt arranged on the conveyer belt wall boards, and a spiral worm matched with the ampoule bottle conveyer belt and a spiral track matched with the spiral worm; the box bracket conveying device comprises a box bracket conveying chain plate which is arranged on the frame and is matched with a chain of the printer. The printer provided by the invention is simple in structure, stable in performance, uniform to ink, clear to print, efficient to print, rapid and convenient for replacing letters, high in production efficiency and convenient to detect, and is automatically controlled.

Owner:ZHENGZHOU SHUNYI TECH CO LTD

Leak-proof device for powder addition of selenium drum

The invention discloses a leak-proof device for powder addition of a selenium drum. The selenium drum is provided with a powder storage bin, wherein a circle of clamping bulge is arranged on an innerwall of the powder storage bin in a surrounding manner; the leak-proof device is detachably propped against the top end of the clamping bulge and comprises a connection pipe, a first powder leaking pipe, a second powder leaking pipe, a blocking assembly and a bracket; a first support net is horizontally clamped into the connection pipe; a second support net is horizontally clamped into the first powder leaking pipe; the second powder leaking pipe communicates with the first powder leaking pipe; the blocking assembly comprises a support column, a limiting plug, a sealing plug and a first springwhich are fixedly connected in sequence from bottom to top; the bracket comprises a pair of L-shaped support rods, a pair of connecting rods and a positioning frame; an inner thread matched with an opening of a carbon powder bottle is arranged in the upper end of the first powder leaking pipe; and the positioning frame is pushed, the edge of the lower end of the second powder leaking pipe is propped against limiting lugs and carbon powder in the carbon powder bottle enters the powder storage bin. The leak-proof device is simple in structure, convenient to use, free of carbon powder leakage and high in powder adding efficiency, pollution-free powder addition is achieved and powder addition can be immediately stopped at any time.

Owner:北海市天硌打印耗材有限公司

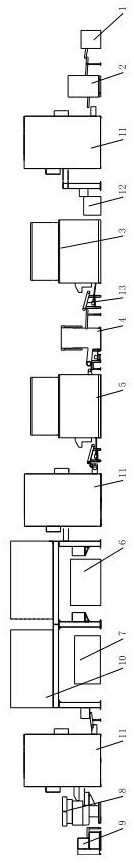

High-speed hose production line

ActiveCN113799421ASimple body structureReasonable layoutLiquid surface applicatorsCoatingsColor printingManufacturing engineering

The invention relates to the technical field of hose production, in particular to a high-speed hose production line. A cold extruding machine, a threading machine, an annealing furnace, an inner spraying machine, a curing furnace, a bottom color machine, a drying oven, a multi-color printing machine, a drying oven, a cap twisting machine and a tail coating machine are sequentially connected. According to the high-speed hose production line, the cold extruding machine, the threading machine, the annealing furnace, the inner spraying machine, the curing furnace, the bottom color machine, the drying oven, the multi-color printing machine, the drying oven, the cap twisting machine and the tail coating machine are integrated into the whole production line, high-speed production of the aluminum hose is achieved, the domestic blank is filled up, and the production efficiency is high.

Owner:常州锡润机械制造有限公司

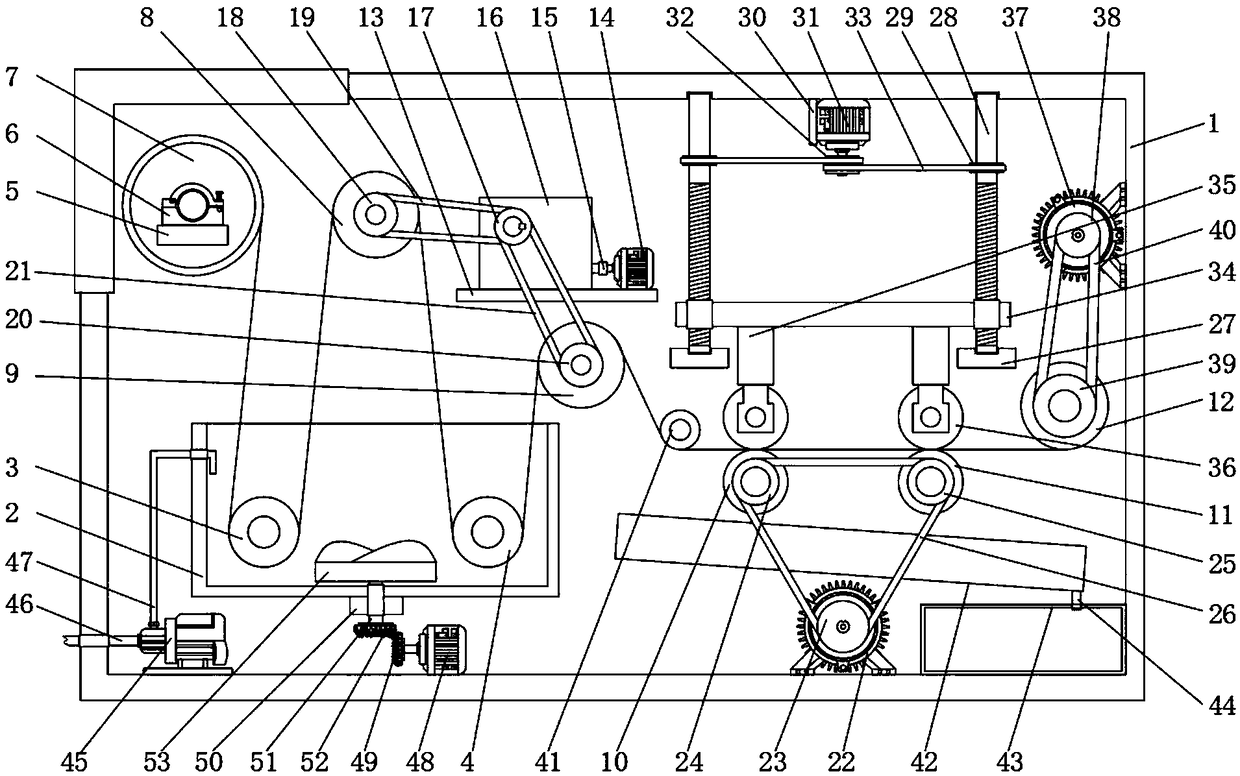

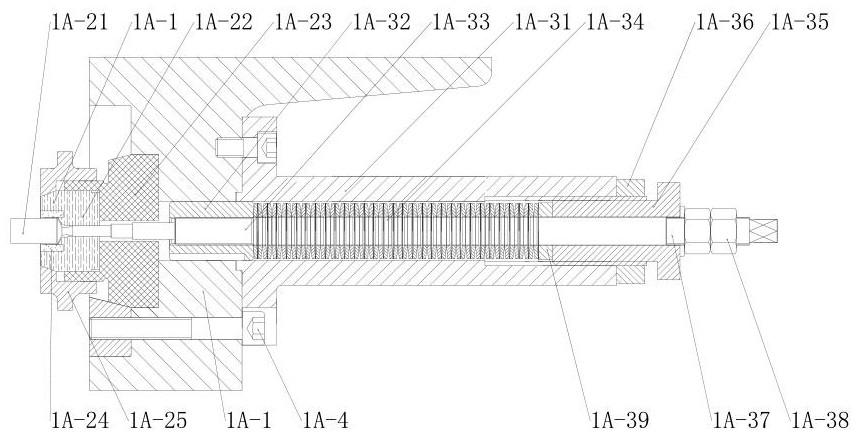

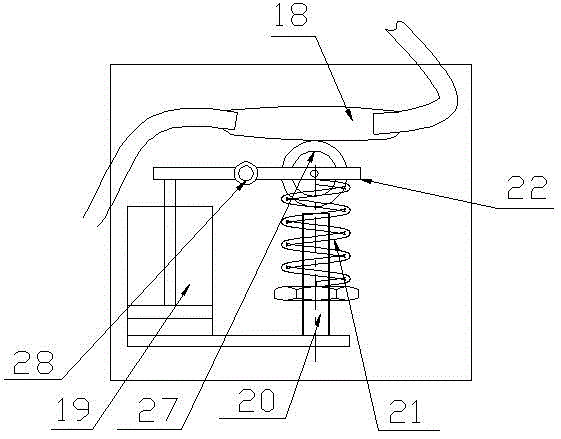

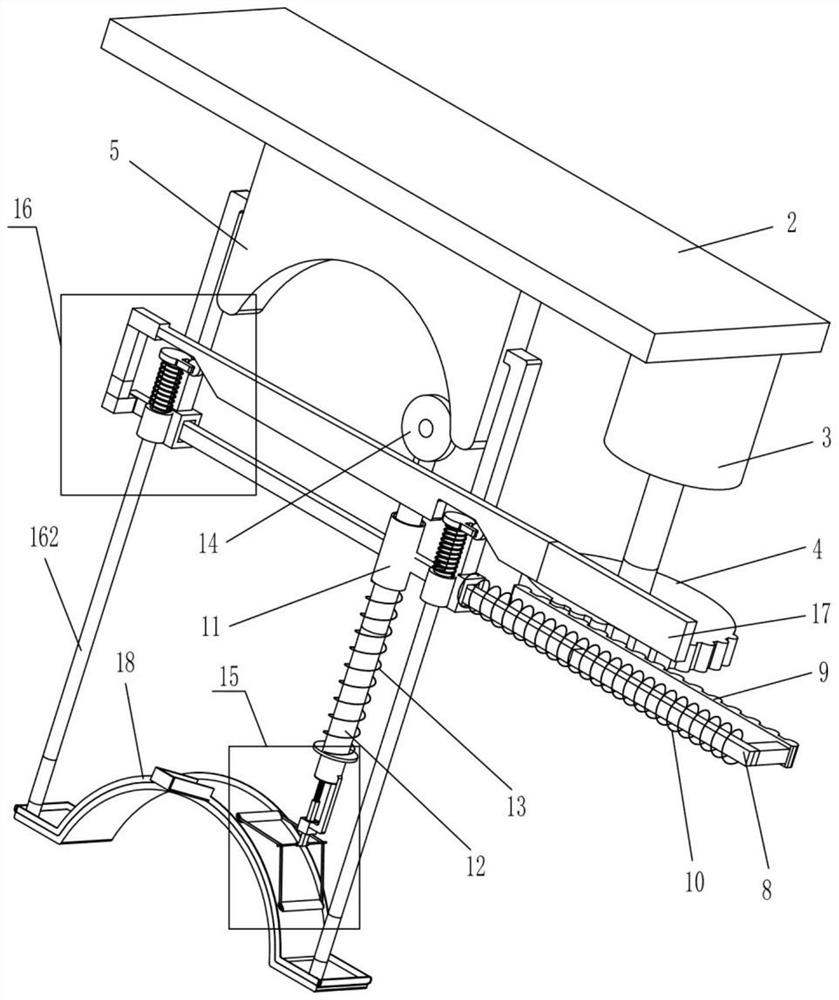

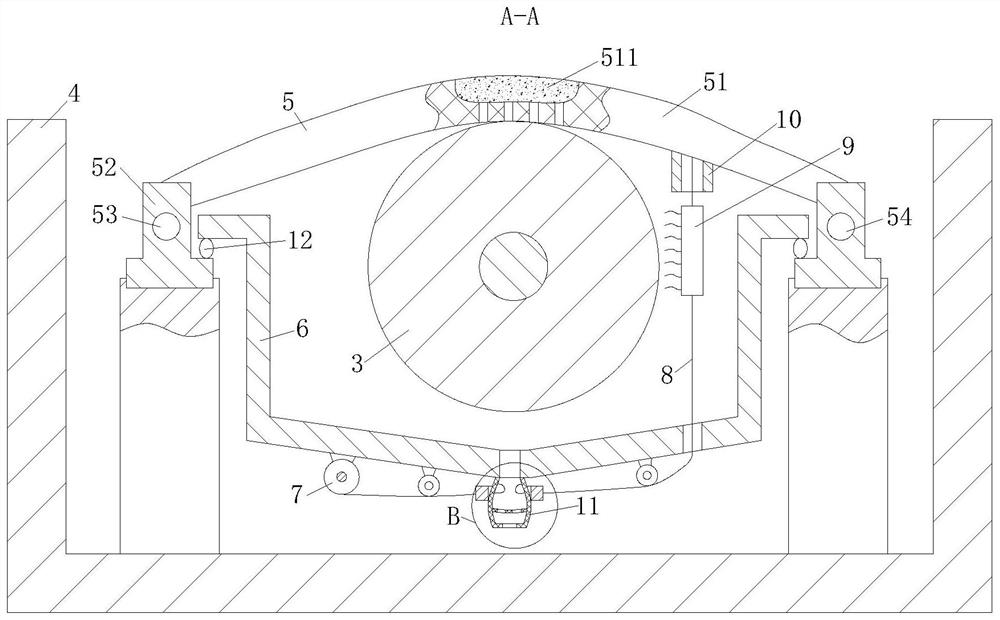

An automatic inking device with hydraulic and pneumatic transmission

ActiveCN103802462BGuaranteed printing qualityHigh degree of automationPrinting press partsGear wheelEngineering

The invention relates to an automatic inking device, in particular to a hydraulic and pneumatic transmission automatic inking device which is mainly applied to an inking mechanism of an inkwriter used in the pharmaceutical packaging machinery industry. The hydraulic and pneumatic transmission automatic inking device comprises a mechanical transmission mechanism, an oil cylinder ink conveying mechanism, a diversion control mechanism and a machine frame. The machine frame comprises a pull rod, a bottom plate and an oil cylinder fixing plate, wherein the pull rod is arranged between the oil cylinder fixing plate and the bottom plate to support the oil cylinder fixing plate and the bottom plate. The mechanical transmission mechanism comprises a motor, a lead screw, a first gear and a second gear, wherein the lead screw is perpendicularly installed on the bottom plate, the first gear is coaxially connected with the motor, the lead screw and the second gear are fixedly arranged in a sleeved mode, and the first gear is meshed with the second gear. By the adoption of the PLC programmable control technology, the hydraulic and pneumatic transmission automatic inking device is high in automation degree and even in inking, brings convenience to adjustment of the inking quantity and guarantees printing quality of the inkwriter.

Owner:龙岩市恒悦机械设备有限公司

Printing ink and printing method for plastic packaging bags

InactiveCN109181410ABright colorStrong adhesionInksOther printing apparatusPolymer scienceAcrylic resin

The invention discloses a printing ink and a printing method for plastic packaging bags. The printing method comprises the steps: mixing peach gum and Arabic gum matched food-grade nanometer titaniumdioxide and food-stage calcium carbonate to prepare a mixture A; adding carboxymethyl cellulose to a solution of the mixture A to carry out ultrasonic treatment to obtain a mixture B; then, mixing anddispersing water-soluble acrylic resin and the like to obtain a mixture C; and mixing the mixture B and the mixture C, adding a food-grade pigment and the like for color modulation to obtain emulsified and homogenized printing ink, and filling an ink cartridge with the printing ink for conventional plastic bag printing. The printing ink for the plastic bag, prepared by mixing a peach gum and Arabic gum hydrolysate and other food-stage materials, is bright in color, strong in adhesive force, uniform in inking, not easy to fade and capable of effectively ensuring that damage cannot happen during storage, transportation and shelf life.

Owner:铜陵尚美新材料包装有限公司

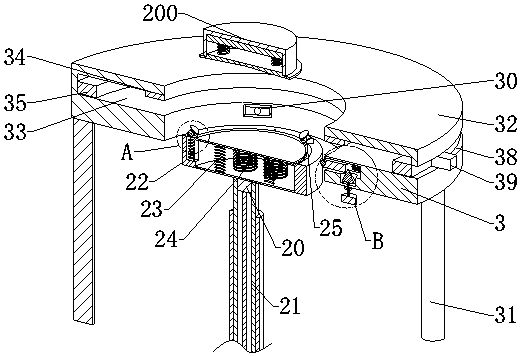

A multi-link ink supply mechanism for a book printing machine

ActiveCN113246609BPrevent precipitationSpray evenlyPrinting press partsStationary filtering element filtersEngineeringProcess engineering

The invention belongs to the technical field of book printing machines and discloses a multi-link ink supply mechanism for book printing machines. The multi-link ink supply mechanism for a book printing machine includes a printing roller, an ink supply shell is arranged above the printing roller, an equipment shell is fixedly connected to the upper surface of the ink supply shell, and the upper surface of the ink supply shell is located on the equipment The front and rear sides of the shell are fixedly connected with installation rods, the ink supply shell is provided with an ink supply mechanism, the upper surface of the ink supply shell and located in the equipment shell are respectively fixedly installed with an ink barrel and a delivery pump, and the feed end of the delivery pump It communicates with the ink barrel, and a filter barrel is fixedly installed on the inner top wall of the equipment shell. The book printing machine uses a multi-link ink supply mechanism. Using the design of the ink supply mechanism, the ink distribution box can filter and stir the ink during the ink supply process to avoid ink precipitation and ensure that the ink can be evenly sprayed on the surface of the printing roller. The printing roller is uniformly inked, the product quality is improved, and the production cost is further reduced, and the problems raised in the background technology are solved.

Owner:长沙金鹰印务有限公司

Food packaging paper

InactiveCN105714612AWide range of raw materialsMild responseFlexible coversWrappersWaxy cornMoisture resistance

The invention discloses food packaging paper. The food packaging paper is characterized in that the food packaging paper is prepared from glycerin, eleusine indica, cynodon dactylon, equisetum ramosissimum, waxy corn starch and citrate. The food packaging paper has the advantages that raw material sources are wide, reaction is mild, the food packaging paper is free of toxin and environmentally friendly, and the food packaging paper accords with the 'green chemistry' concept of a modern requirement. The food packaging paper is environment-friendly and safe food packaging paper. The raw materials are easy to obtain, operation is easy, cost is low, and the food packaging paper is economical and environmentally friendly. By means of paper pulp raw materials made by processing eleusine indica, cynodon dactylon, equisetum ramosissimum and waxy corn starch, paper forming strength is high, flexibility is good, the paper is not prone to breakage, the application range is wide, the smoothness and the printing adaptability are high, inking of the packaging paper can be more uniform, the food packaging paper is suitable for printing of various surfaces and can be completely degraded, and the packaging paper is good in moisture resistance.

Owner:CHAOHU JINBANG PLASTIC PACKAGING

A fast double-sided date and batch number printer

The invention discloses a quick double-faced date and batch number printer which comprises a rack, a feeding part, printing parts, a discharging part and a motor. The printing parts comprise the upper printing part and the lower printing part which are of the same structure, the upper printing part comprises an upper lettering rotating shaft and an upper printing ink fixing shaft which is mounted on one side of the upper lettering rotating shaft, and the upper lettering rotating shaft is provided with a box walking wheel and a lettering assembly. The lettering assembly comprises a rubber letter nail, a letter nail clamping seat, a fixing shaft and a bearing, the bearing is detachably fixed on the lettering rotating shaft, the fixing shaft is provided with a buffer spring, one end of the fixing shaft is fixed on the bearing, the letter nail clamping seat is fixed at the other end of the fixing shaft, and the rubber letter nail is mounted on the letter nail clamping seat. The motor is in transmission connection with the printing parts, the feeding part and the discharging part. According to the quick double-faced date and batch number printer, batch numbers and dates can be printed on the upper face and the lower face of a packaging box at the same time in a printing ink stamped mode, the printing accuracy is high, the speed is high, and the effect is good.

Owner:QINGDAO JINGSHENG COLD FRESH FOOD CO LTD

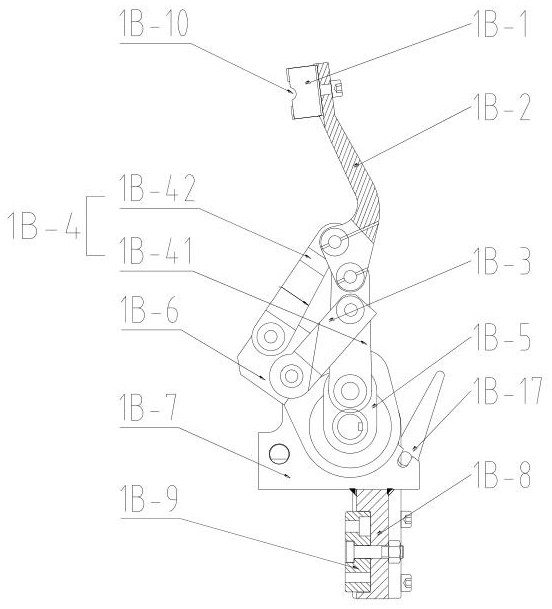

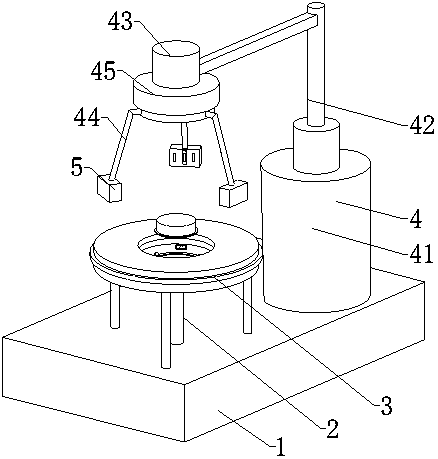

A printing inking device

ActiveCN110395046BSolve the problem of uniformity of applicationInk evenlyStationary filtering element filtersPrinting press partsElectric machineryPrinting ink

The invention discloses an inking device for printing. An ink storage device is fixedly installed on the top of the first support plate. An electric push rod is fixedly installed on the inner side of the first support plate. Ink device, one end of the telescopic hose communicates with the bottom of the ink storage device, and the other end communicates with the top of the ink transfer device, the bottom of the first support plate is fixedly installed with a drive assembly, and the driving motor of the present invention drives the connecting shaft to make the two A roulette drives the polygonal concave plate to rotate intermittently, and the polygonal concave plate drives the ink transfer roller to rotate intermittently. At the same time, the electric push rod drives the soft brush to perform circular reciprocating motion on the surface of the ink transfer roller, so that the ink passes through the soft brush evenly and comprehensively. Brushing to the surface of the ink transfer roller, the invention solves the problem of uniformity of ink smearing, the ink is applied evenly, the inking process is stable, and the work efficiency is improved.

Owner:东莞同森印刷有限公司

A helmet printing device

Owner:陈余

Anti-leakage powder device for toner cartridge refilling

The invention discloses an anti-leakage powder device for adding powder to a toner cartridge. The toner cartridge has a powder storage bin, and a ring of locking protrusions is arranged on the inner wall of the toner storage bin. The anti-leakage powder device is detachably pressed against the top of the protrusion. Including: connecting pipe, the first supporting net is horizontally clamped inside; the first powder leaking tube, the second supporting net is horizontally clamped inside; the second powder leaking tube is connected with the first powder leaking tube; the plugging component , including a support column, a limit plug, a sealing plug, and a first spring fixed in sequence from bottom to top; a bracket, including a pair of L-shaped struts, a pair of connecting rods, and a positioning frame; wherein, the first powder leakage pipe The upper end is provided with an internal thread that matches the mouth of the toner bottle. When the positioning frame is pressed down, the lower end edge of the second powder leaking tube abuts against the limit tab, and the toner in the toner bottle enters the toner storage bin. The invention has simple structure and convenient use, realizes pollution-free powder feeding, can stop powder feeding immediately at any time, has no carbon powder leakage, and has high powder feeding efficiency.

Owner:北海市天硌打印耗材有限公司

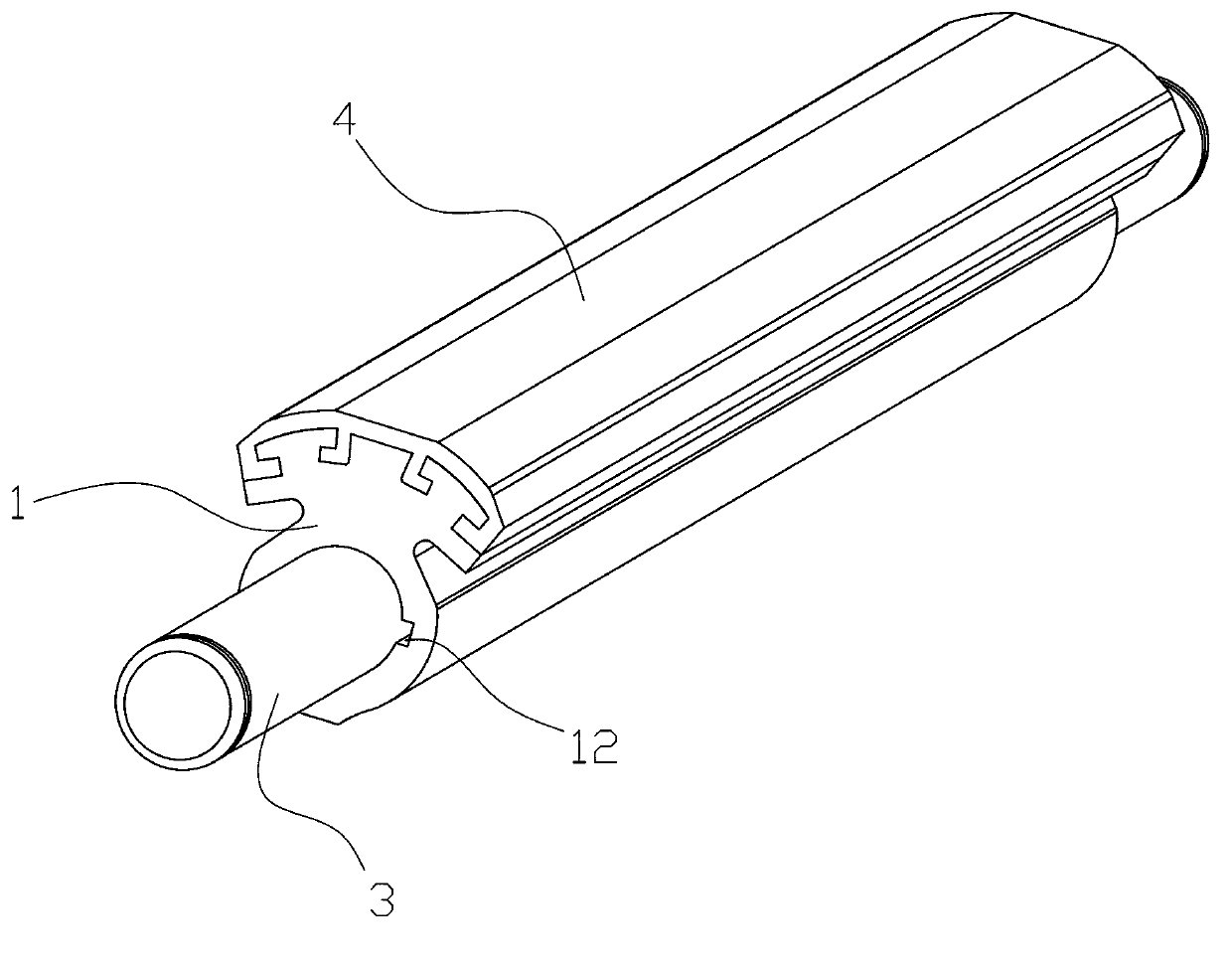

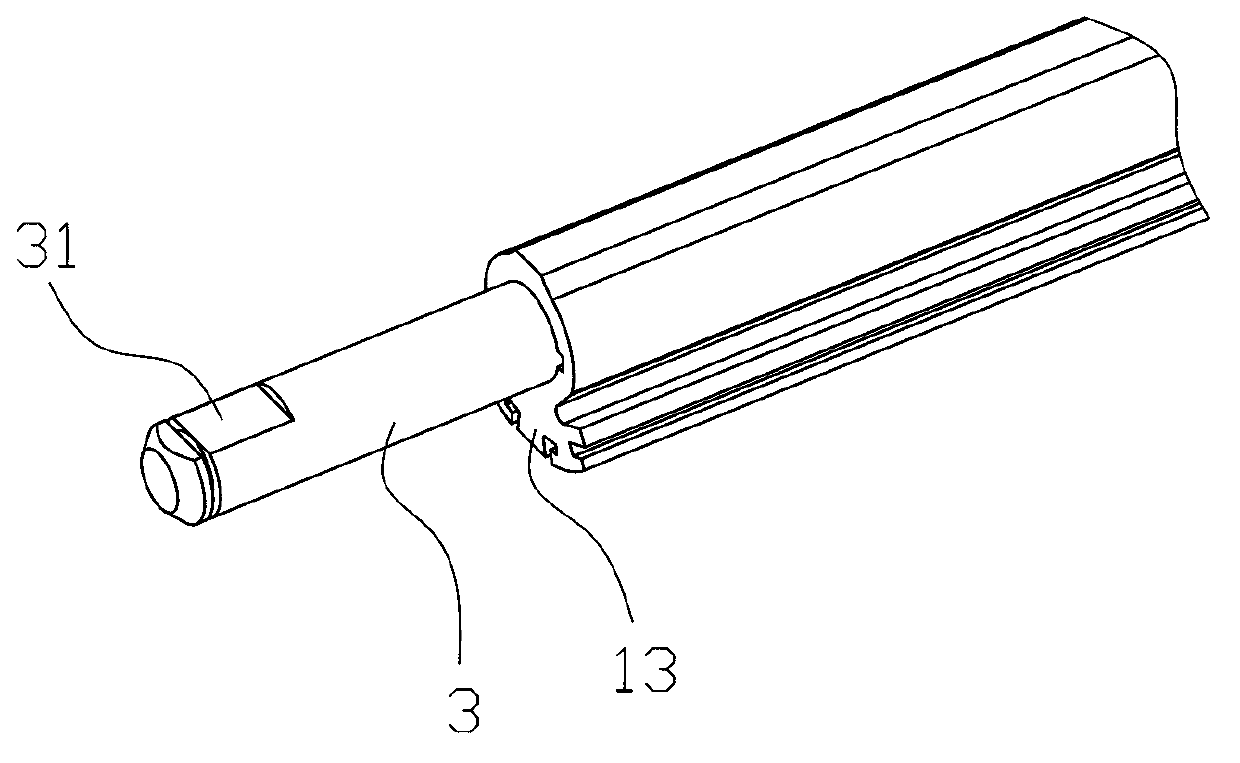

Plane printing roller

The invention discloses a plane printing roller and relates to a needle type printer. The plane printing roller comprises two rubber layers and a solid metal layer, wherein the two rubber layers and the solid metal layer are bonded together through two elastic buffering layers. The thickness of each rubber layer is 2-3mm. Printing planes are arranged at the ends, far away from the elastic buffering layers, of the rubber layers. Inclined planes are arranged at two sides of the printing planes. The rubber layers and the elastic buffering layers are arranged symmetrically with respect to the solid metal layer. Mounting heads are fixedly connected with the two sides of the solid metal layer and are connected with an external printer frame. The plane printing roller can solve the problems thata large amount of noise is generated, the printing quality is poor, and outer-layer rubber needs to be replaced integrally due to partial damage when a needle type printer works in the prior art.

Owner:安徽宁国天嘉橡塑制品有限公司

Flat plate printing equipment

The invention relates to the technical field of printing and discloses flat plate printing equipment. The flat plate printing equipment comprises a rack. A printing machine seat is connected with therack in a sliding mode, a forme is fixed on the printing machine seat, and a working table is connected with the rack in a sliding mode. The working table is vertical to the sliding direction of the printing machine seat. A ratchet wheel is rotatably connected with the rack. A crank and a first gear are coaxially connected with the ratchet wheel. A connecting rod is rotatably connected with the crank. One end of the connecting rod is rotatably connected to the working table. An ink plate is connected with the rack in a sliding mode, the ink plate is located under the printing machine seat, anda spline is fixed on the ink plate. A second gear meshed with the spline is rotatably connected with the rack. A driving mechanism for driving the second gear to rotate intermittently is arranged onthe rack. A supporting rod is fixed on the spline. A ratchet pawl meshed with the ratchet wheel is fixed on the supporting rod. A transmission rod is fixed on the printing machine seat, wheel teeth are arranged on the transmission rod, and the transmission rod is meshed with the first gear by the wheel teeth. According to the flat plate printing equipment, ink feeding can be automatically and uniformly carried out, and meanwhile ink on materials can be dried quickly.

Owner:普天印务(重庆)股份有限公司

Printing machine convenient to clean residual materials

The invention discloses a printing machine convenient to clean the residual materials. the printing machine comprises a main body, an ink cylinder, a conveying belt and fixed round columns, an ink boxis arranged above the main body, the ink box and the main body are fixedly through nuts, an ink inlet is formed in the upper portion of the ink box, spray heads are connected below the ink box, the ink cylinder is arranged below the spray heads, the ink cylinder is connected with the main body through screws, an ink roller is arranged below the ink cylinder, a blade is arranged on the periphery of the ink roller, adjusting rods are arranged on the left side and the right side of the blade, bolts penetrate through the adjusting rod, the bolt and the adjusting rods are in threaded connection, the conveying belt is arranged below the ink roller, a fixing plate is fixed below the conveying belt. According to the printing machine, the spray heads are set, when the spray heads are opened for use, due to the fact that the length of the spray heads and the length of the ink cylinder are the same, the ink cylinder is more uniform in ink feeding, so that the situation that the ink is wasted isreduced.

Owner:凌樱樱

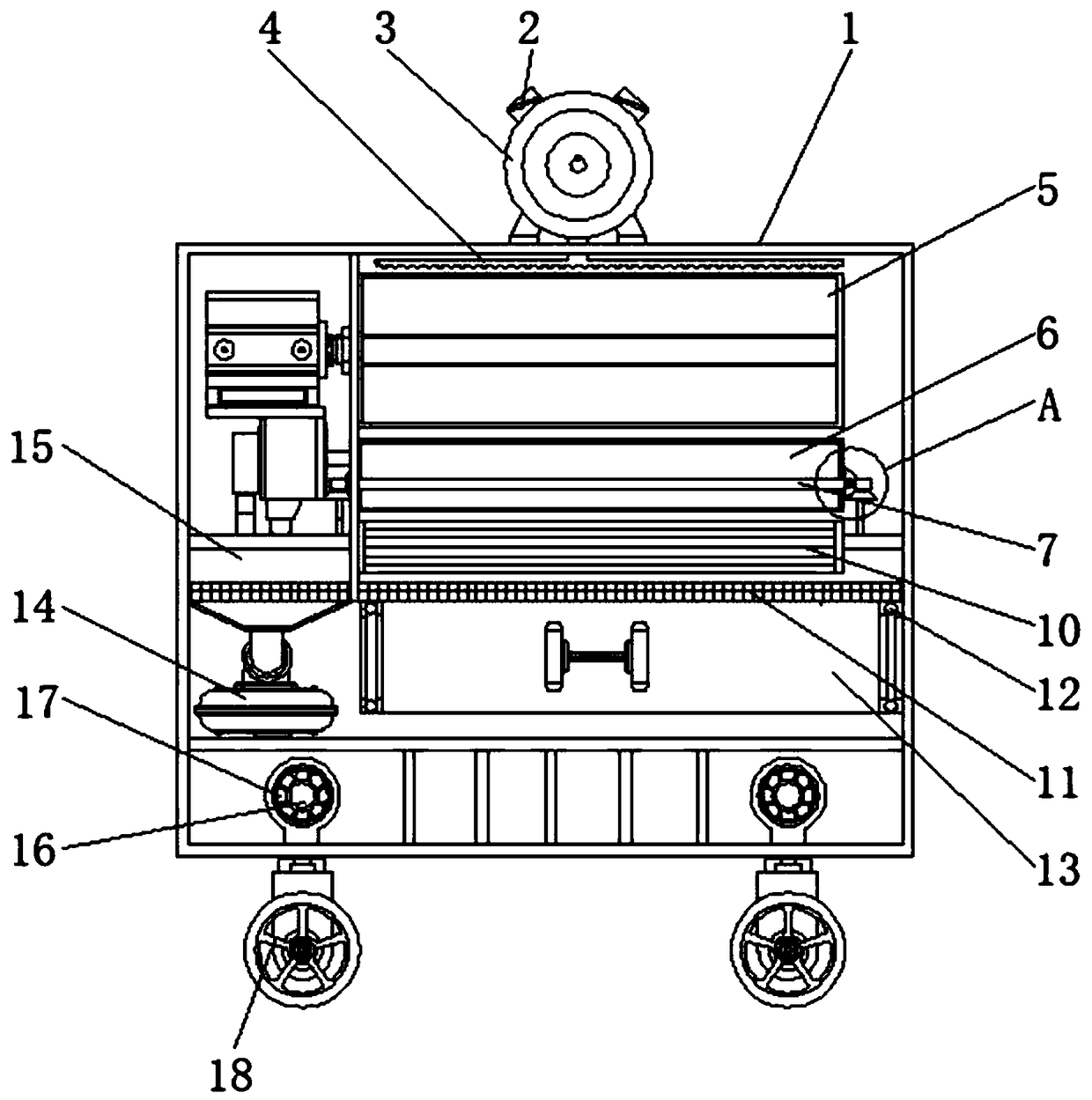

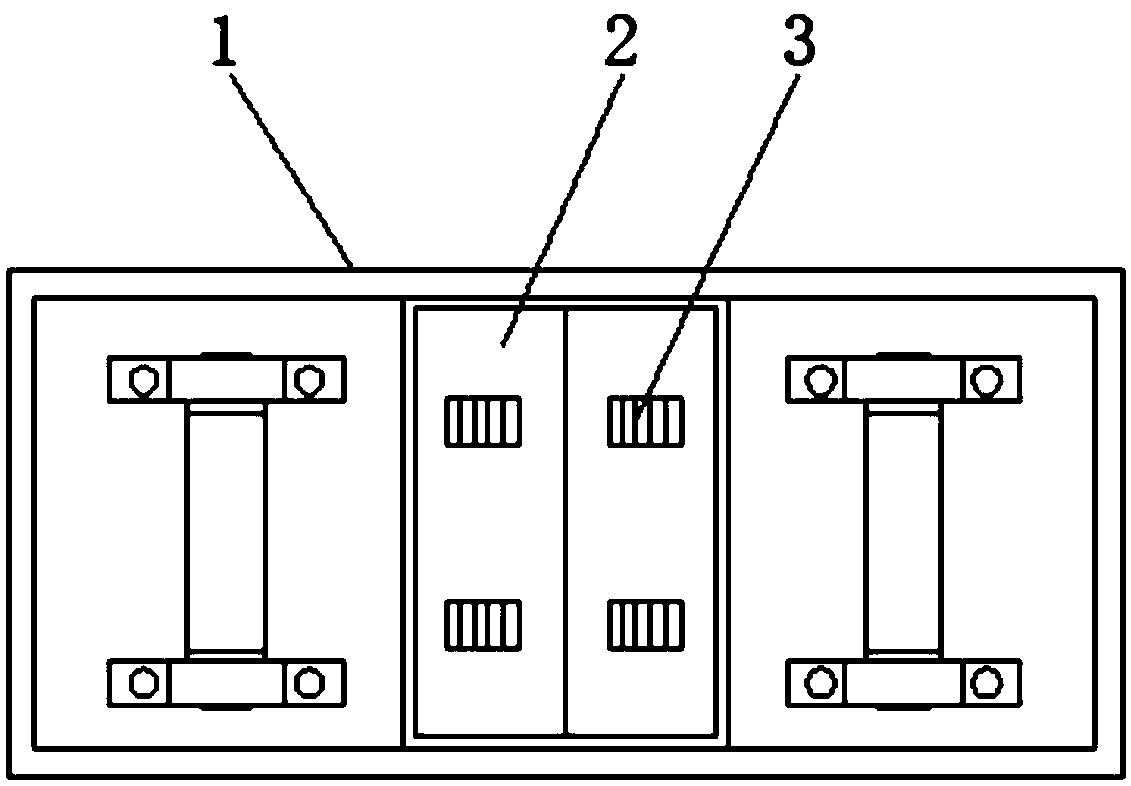

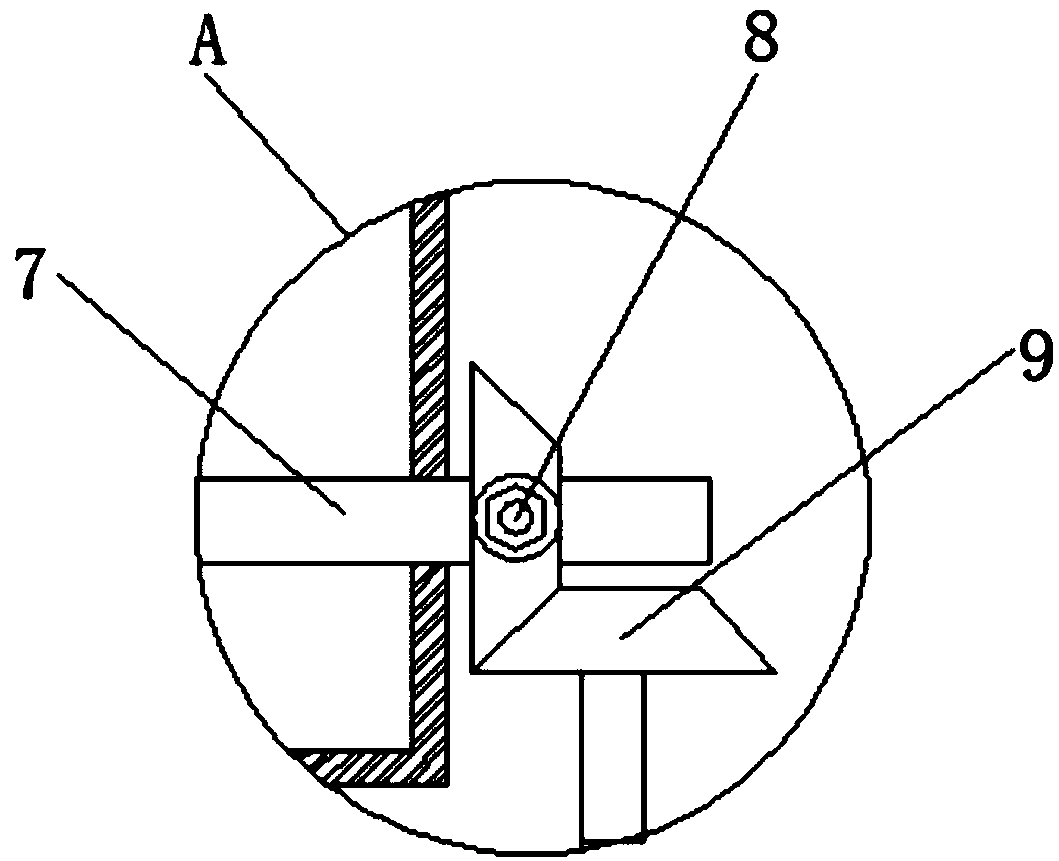

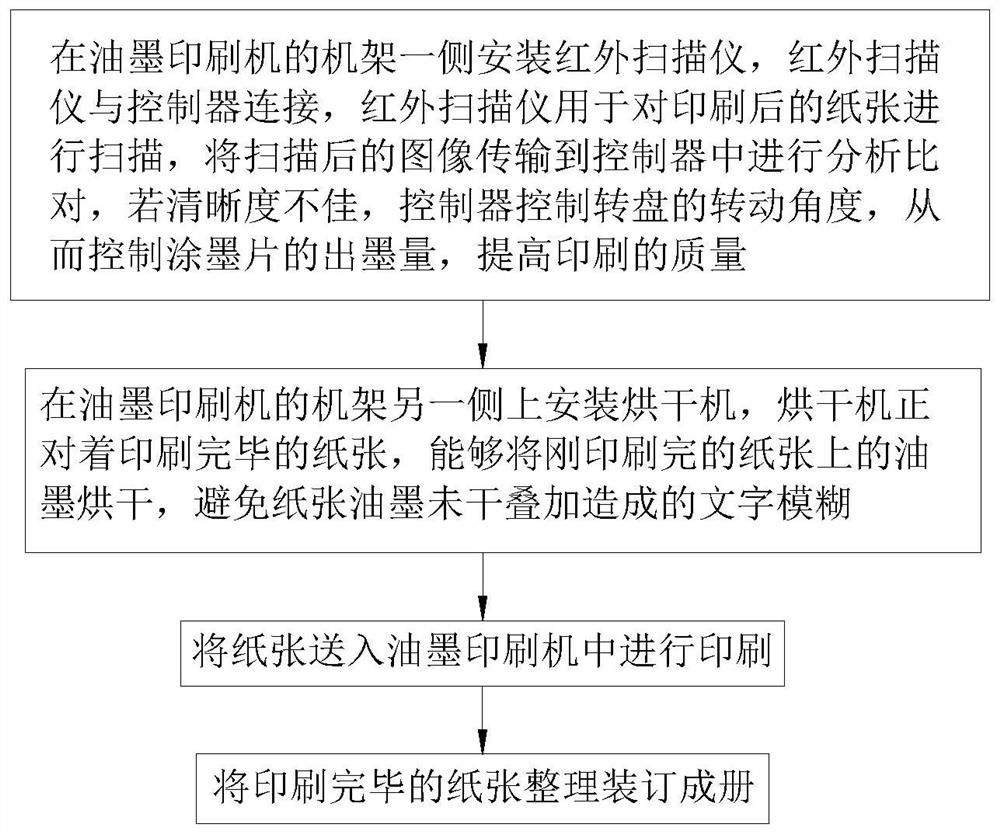

A kind of ink printing optimization method

ActiveCN109397872BAvoid unclearInk evenlyOther printing apparatusPrinting press partsEngineeringPrinting ink

Owner:JINAN WANCHANG PACKAGING PRINTING CO LTD

Inking method and inking device for optical lens

Owner:宁波丞达精机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com