A multi-link ink supply mechanism for a book printing machine

A technology for printing presses and multi-supply, applied in printing presses, general parts of printing machinery, printing and other directions, can solve problems such as increasing production costs, affecting the coating film of printing rollers, incomplete graphics, etc., to reduce production costs, The effect of avoiding ink precipitation and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

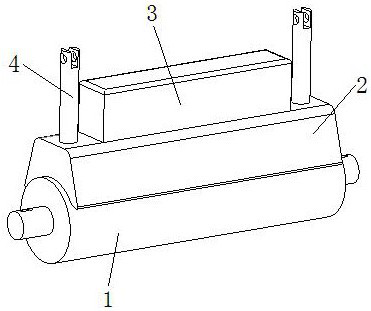

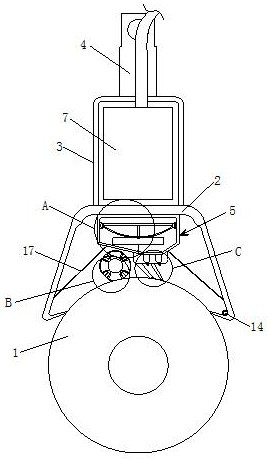

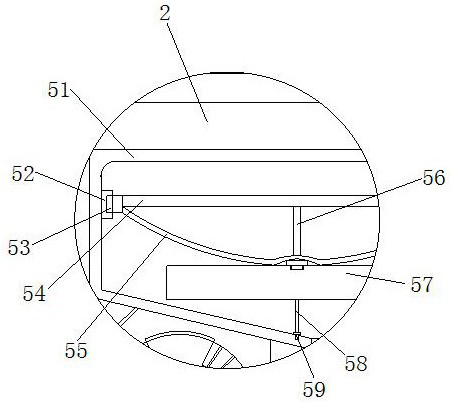

[0028] see Figure 1-8 , the present invention provides a technical solution: a multi-link ink supply mechanism for a book printing machine, including a printing roller 1, an ink supply shell 2 is arranged above the printing roller 1, and an equipment shell is fixedly connected to the upper surface of the ink supply shell 2 3. The upper surface of the ink supply case 2 and the front and rear sides of the device case 3 are fixedly connected with the installation rods 4, the ink supply case 2 is provided with an ink supply mechanism 5, and the upper surface of the ink supply case 2 is located in the device case 3 An ink barrel 7 and a delivery pump 8 are fixedly installed respectively, the feeding end of the delivery pump 8 communicates with the ink barrel 7, a filter barrel 9 is fixedly installed on the inner top wall of the equipment shell 3, and the corresponding position of the top wall of the filter barrel 9 and the equipment shell 3 Jacks 10 are provided in each, and a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com