Plane printing roller

A printing roller, flat technology, applied in the printing device, printing and other directions, can solve the problems of outer rubber damage, loud noise, poor printing quality, etc., and achieve the effects of small thermal expansion and deformation, uniform ink marks, and low printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

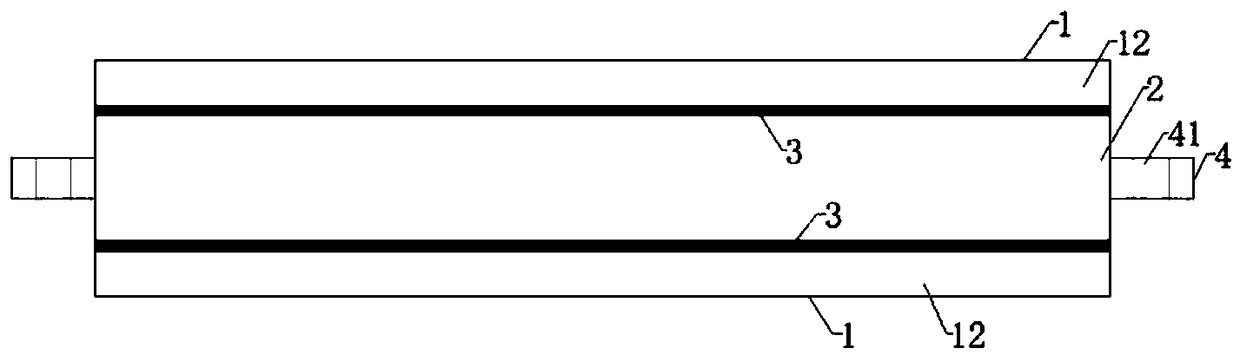

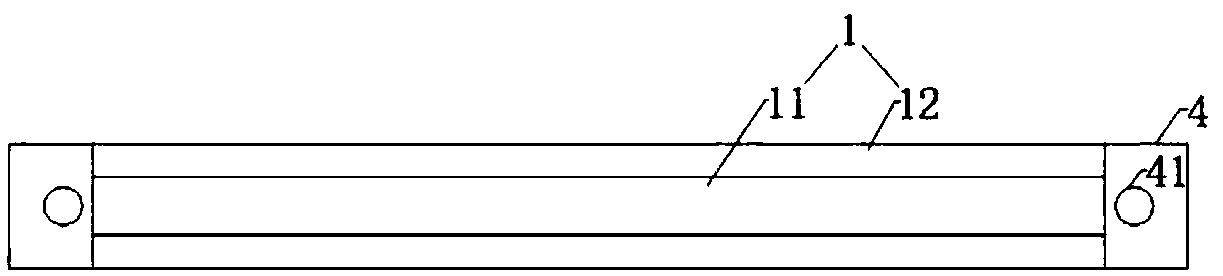

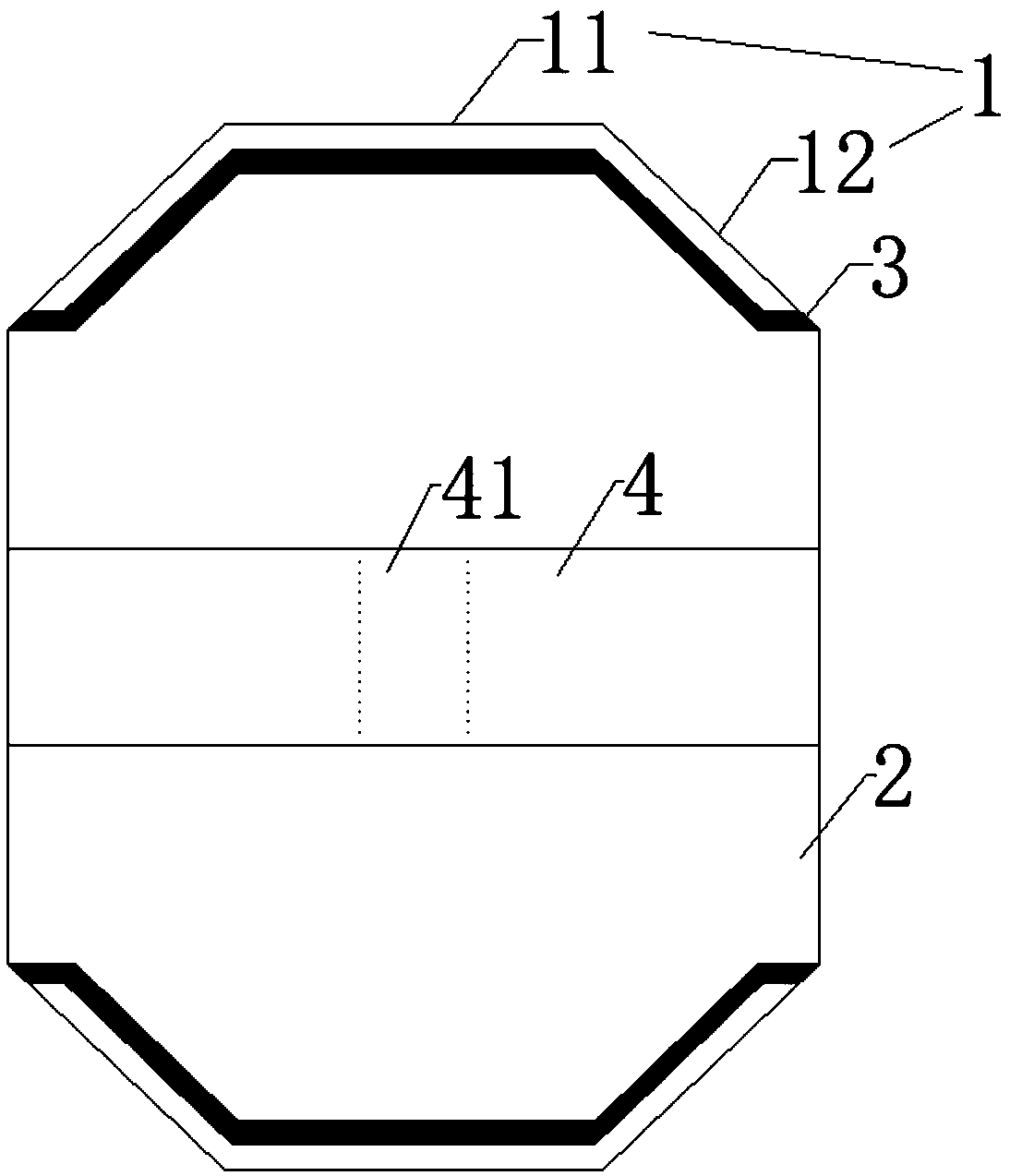

[0017] Such as figure 1 , 2 As shown in and 3, a flat printing roller includes a rubber layer 1 and a solid metal layer 2, the rubber layer 1 and the solid metal layer 2 are bonded by an elastic buffer layer 3, and the thickness of the rubber layer 1 is 2 to 3mm , the printing plane 11 is set at the end far away from the elastic buffer layer 3, and the two sides of the printing plane 11 are provided with slopes 12, the number of the rubber layer 1 and the elastic buffer layer 3 are two, and they are arranged symmetrically with respect to the solid metal layer 2, the solid The two sides of the metal layer 2 are fixedly connected with the installation head 4, and the installation head 4 is connected with the external printer frame. The thickness of the rubber layer 1 is 2.5 mm. Screw holes 41 are provided on the mounting head 4 . The elastic buffer layer 3 is an adhesive layer. The installation head 4 is welded on the side of the solid metal layer 2 .

[0018] When the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com