An automatic inking device with hydraulic and pneumatic transmission

A hydraulic, pneumatic and automatic technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of poor control of ink supply, uneven grinding, and high ink viscosity, and achieve the size of ink supply. The effect of convenient adjustment, guaranteed printing quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

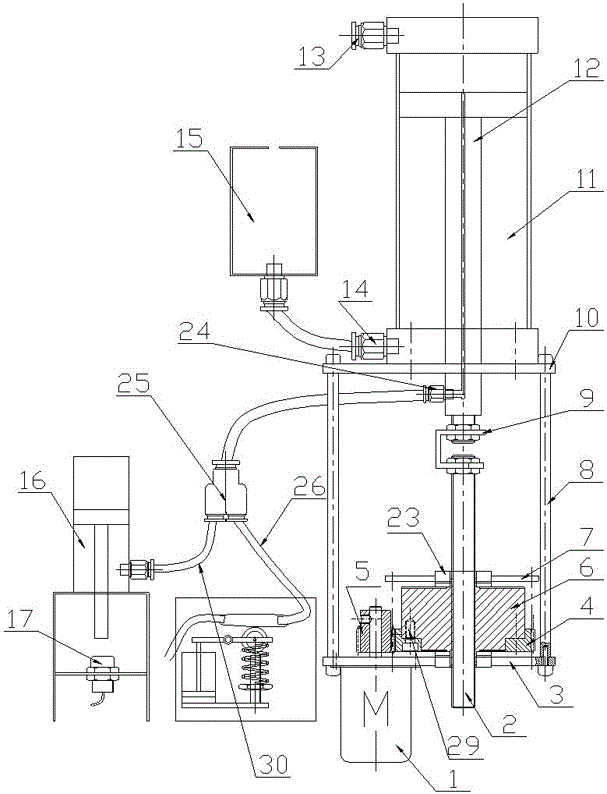

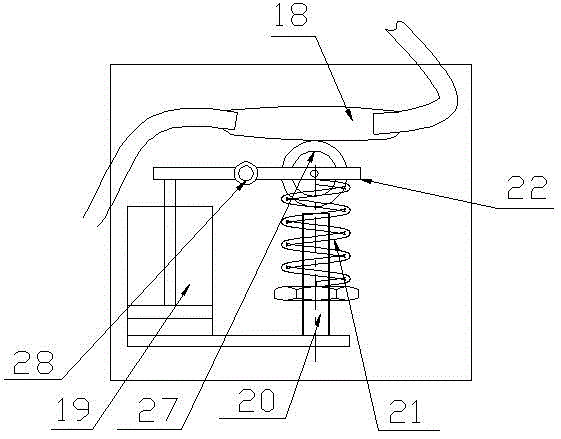

[0019] Below in conjunction with specific embodiment the utility model is described further.

[0020] Such as figure 1 , 2 As shown, a hydraulic and pneumatic transmission automatic inking device includes a mechanical transmission mechanism, an oil cylinder ink transfer mechanism, a flow control mechanism, and a frame. The frame includes a pull rod 8, a bottom plate 3, and an oil cylinder fixing plate 10. The cylinder fixing plate 10 and the base plate 3 are supported by a pull rod 8. The mechanical transmission mechanism includes a motor 1, a lead screw 2, a gear one 5, and a gear two 4. The lead screw 2 is vertically installed on the base plate 3, The first gear 5 is coaxially connected with the motor 1, the screw 2 is fixedly fitted with the second gear 4, and the first gear 5 is meshed with the second gear 4;

[0021] The described oil cylinder ink transfer mechanism comprises an oil cylinder 11, a hollow oil cylinder piston rod 12 installed in the oil cylinder, the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com