Arrangement method of different color ink nozzle for colorful ink jet printer

A color inkjet and printer technology, which is applied in the field of arrangement of ink nozzles of different colors in color inkjet printers, can solve problems such as long distance, influence on ink supply, unstable ink pressure of nozzles, etc., to ensure printing quality and eliminate the same color tone different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

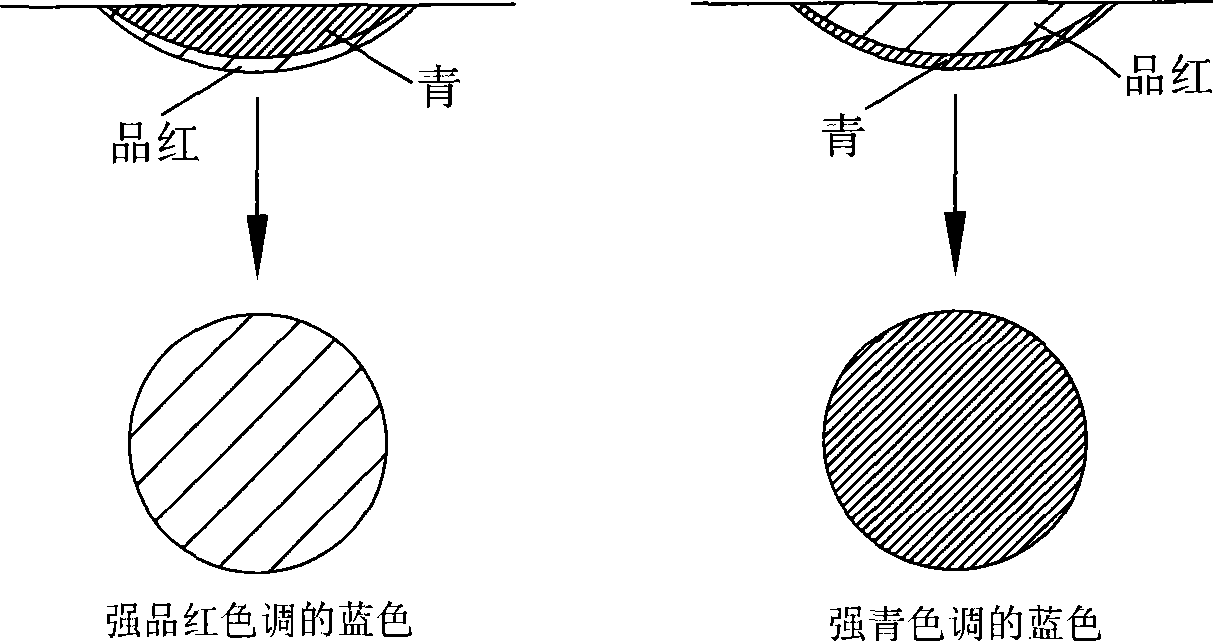

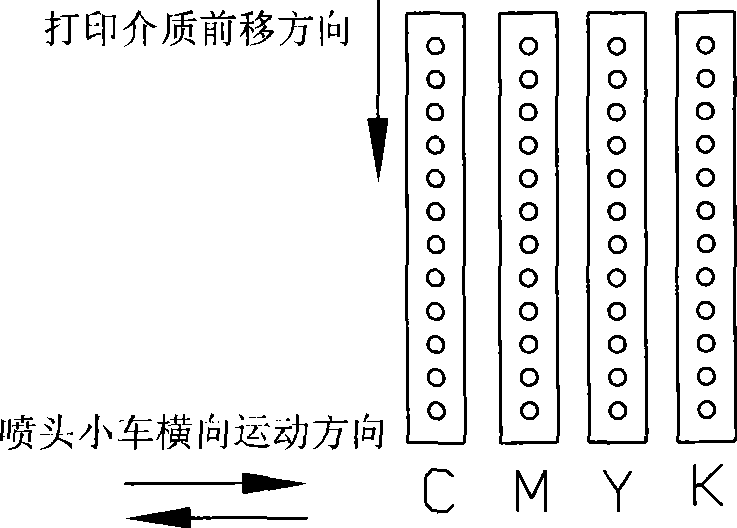

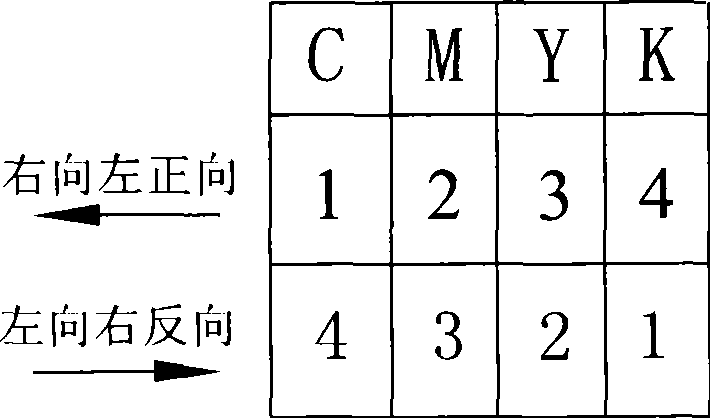

[0020] Such as Figure 3b As shown, the method for arranging the ink nozzles of different colors of the color inkjet printer of the present invention, the specific steps are that the inkjet printer is provided with four nozzles, and each nozzle corresponds to a primary color ink, including C (cyan), M (magenta) , Y (yellow), K (black) inks, the four nozzles are arranged in two rows along the printing medium feeding direction, the colors of the inks in the two nozzles in the front row are K (black) and C (cyan), respectively, and the nozzles in the rear row The colors of the medium inks are M (magenta) and Y (yellow). Such as Figure 3c As shown, in the nth going trip of the nozzle trolley, M (magenta) and Y (yellow) will be covered at one position on the printing medium first, and one position on the printing medium will be covered first during the nth return trip Y (yellow) and M (magenta); after stepping, in the n+rth trip of the printhead trolley, cover K (black) and C (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com