Plane surface printing roller of needle printer

A dot matrix printer and printing roller technology, applied in printing devices, printing, etc., can solve the problems affecting the printing quality of the printer, the overall weight of the printing roller, and the impact on printing quality, and achieve simple and reasonable structure, good noise reduction effect, and printing quality. high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

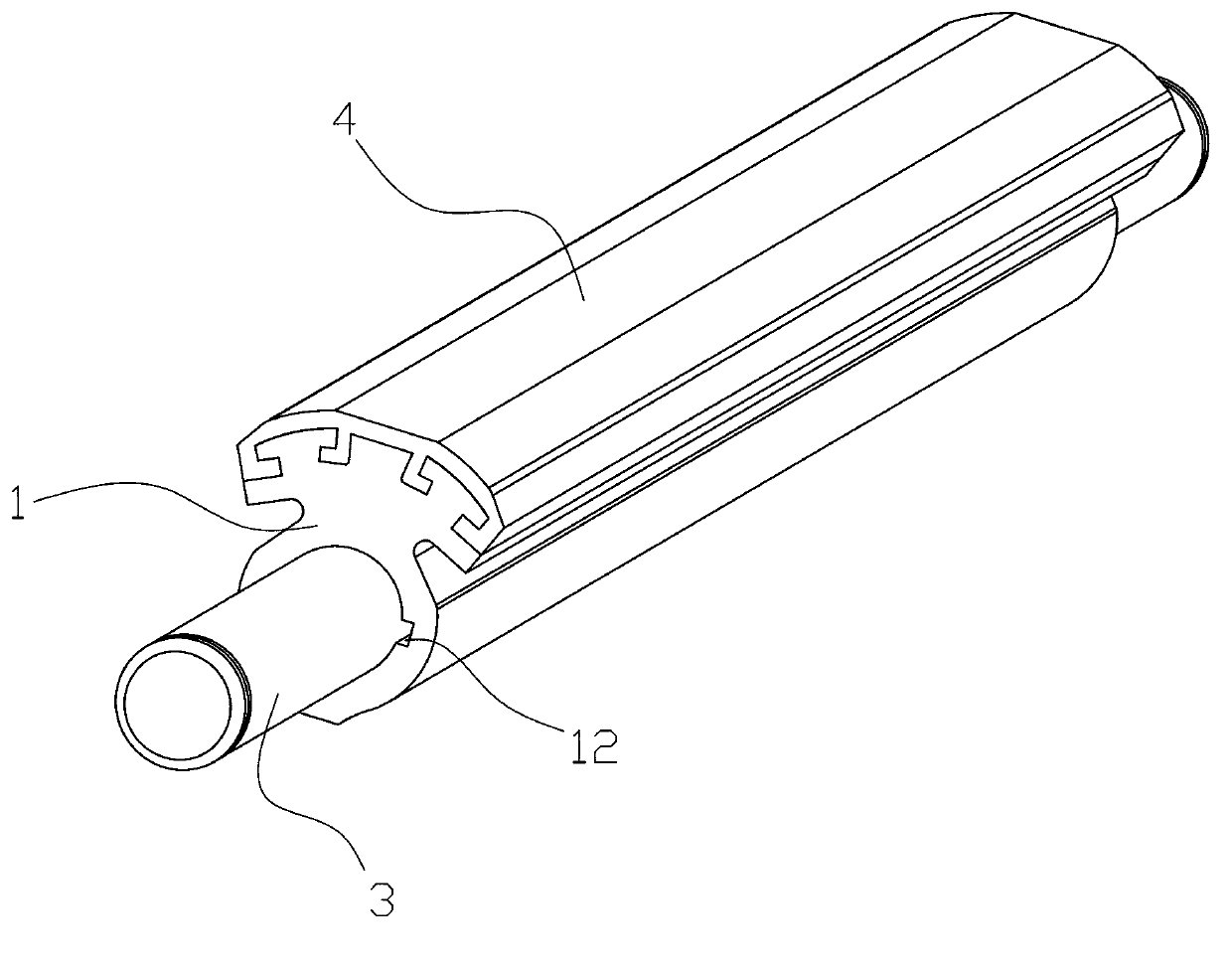

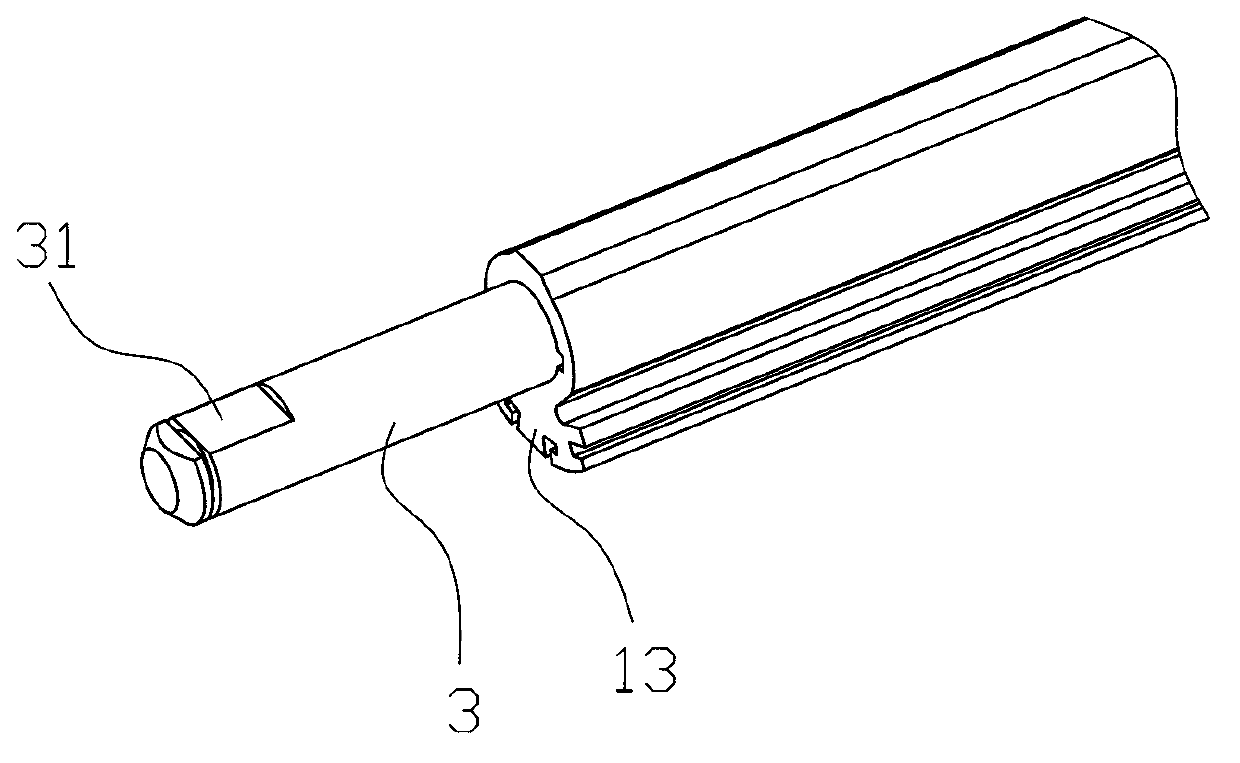

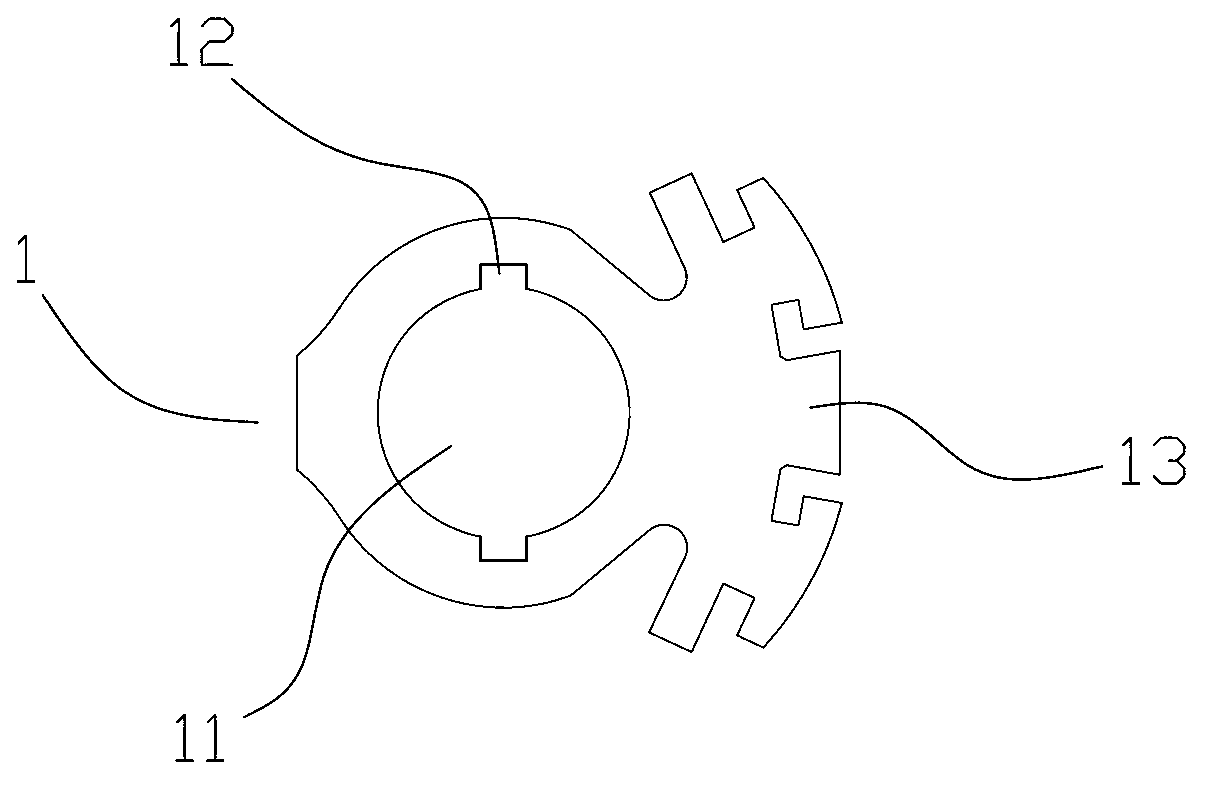

[0016] refer to Figure 1~Figure 3 , a flat printing roller of a dot matrix printer of the present invention, which comprises a support 1, the two ends of the support 1 along its length direction are connected with a support shaft 3 for fixing the support 1 on the printer frame, the support 1 and the support shaft 3 Stainless steel or aluminum alloy materials are used, and shaft holes 11 are preferably provided at both ends of the bracket 1 along its length direction. The support shaft 3 is a round shaft and is interference-fitted in the shaft hole 11 of the bracket 1. The shaft hole 11 There is an exhaust groove 12 along the hole, and the support frame 3 is set as a round shaft to facilitate processing, clamping, inspection, assembly and positioning with high precision. The support shaft 3 is interference fit into the shaft hole 11 of the bracket 1 to ensure that the support shaft 3 and the bracket 1 will not move relative to each other during the working process, and the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com