A helmet printing device

A technology for printing devices and safety helmets, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of poor printing effect, cumbersomeness, and affecting the printing quality of helmet characters and patterns, so as to improve printing effect and quality, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

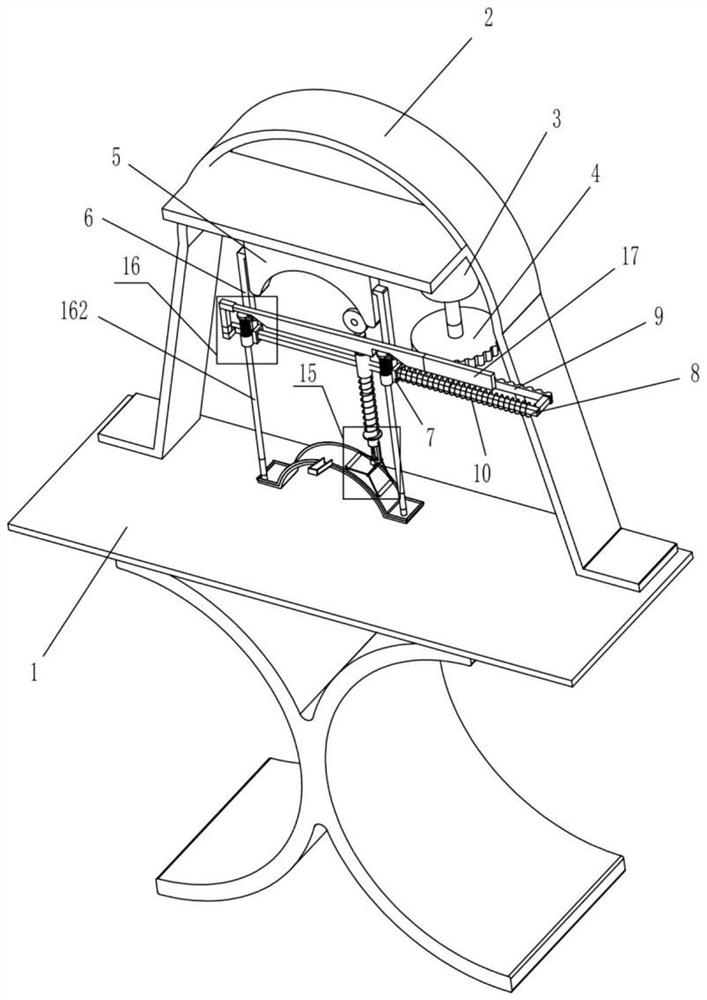

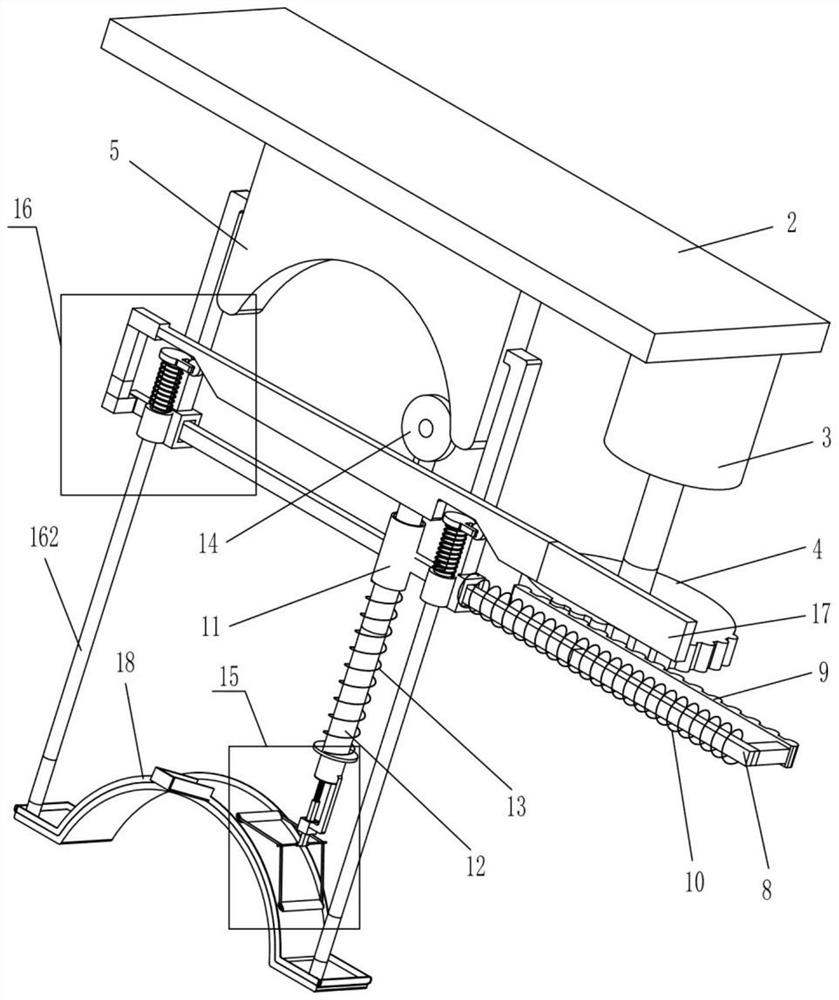

[0021] A kind of safety helmet printing device, refer to figure 1 and figure 2 As shown, it includes a frame 1, a mounting plate 2, a motor 3, a gear 4, an arc plate 5, a vertical arm 6, a fixed sliding sleeve 7, a lateral movable rod 8, a rack 9, an elastic part 10, a cylindrical Sliding sleeve 11, cylindrical movable rod 12, elastic part two 13, extruding small wheel 14, inking mechanism 15, extruding mechanism 16, extruding plate 17 and printing module 18, described frame 1 is provided with mounting plate 2. A motor 3 is installed on the right side of the bottom side of the installation plate 2, a gear 4 is arranged on the output shaft of the motor 3 through a rotating shaft, and an arc-shaped plate 5 is arranged on the middle part of the bottom side of the installation plate 2. Two vertical arms 6 are fixedly installed in the middle of both sides of the arc-shaped plate 5, and two fixed sliding sleeves 7 are fixedly installed at the bottom ends of the two vertical arms 6...

Embodiment 2

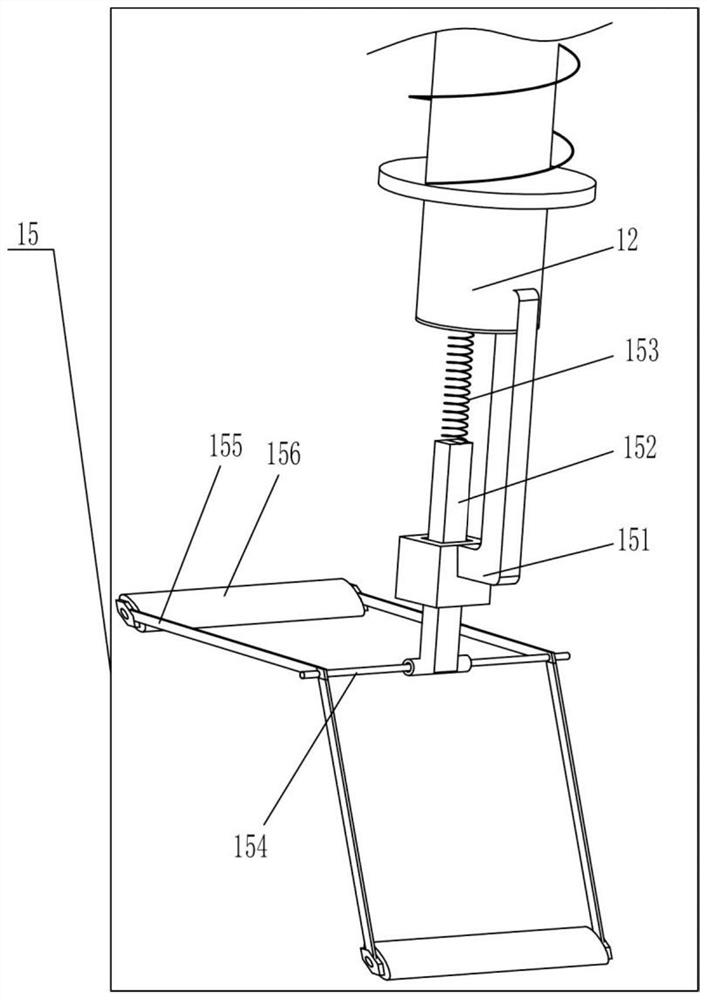

[0026] refer to image 3 As shown, the main difference between this embodiment and Embodiment 1 is that in this embodiment, the ink application mechanism 15 includes a connecting arm 151, a guide rod 152, an elastic member 3 153, a rotating rod 154, a mounting rod 155 and a coating wheel 156, the right side of the lower end of the cylindrical movable rod 12 is provided with a connecting arm 151, and the middle part of the bottom end of the cylindrical movable rod 12 is provided with an elastic member 3 153, and in this embodiment the elastic member 3 153 is the first Two return springs, the bottom end of the connecting arm 151 is provided with a guide hole and a guide rod 152 is slidably arranged in the guide hole, and the guide rod 152 can move up and down in the guide hole, and the upper end of the guide rod 152 is in contact with the elastic The third part 153 is connected, the lower end of the guide rod 152 is provided with a round hole and a rotating rod 154 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com