Ink applying device capable of preventing ink misting

An ink flying and anti-flying technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of large ink splash, large waste, and large ink waste, so as to improve printing quality, reduce costs, and prevent ink staining. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

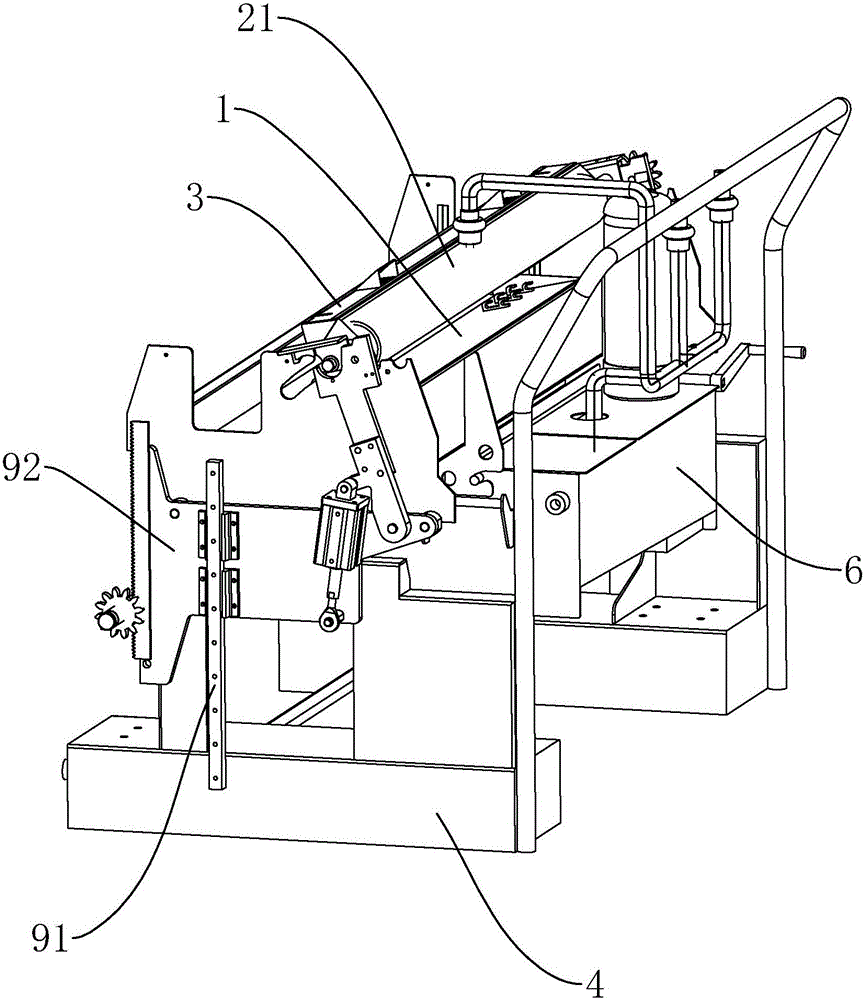

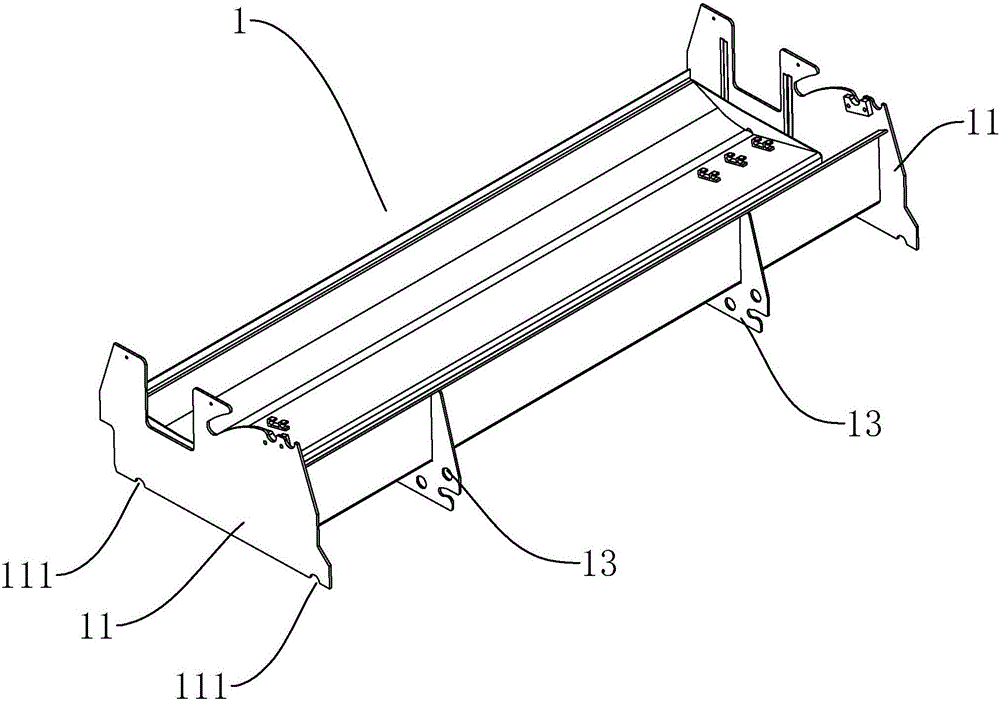

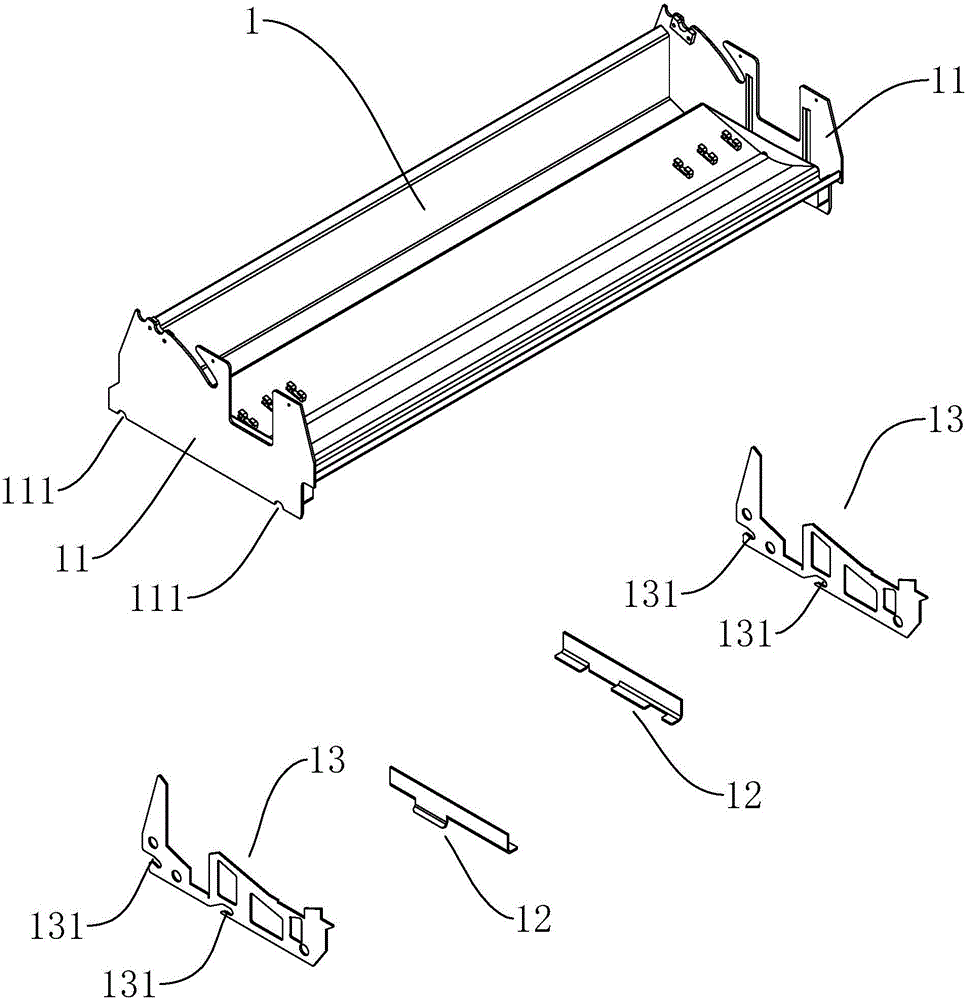

[0027] refer to Figure 1 to Figure 10 , Figure 1 to Figure 10 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, an inking device for preventing ink splashing includes a frame, an ink basin 1, an ink transfer roller mechanism, and an ink splash prevention mechanism 3. The ink transfer roller The mechanism includes an ink transfer roller 21 arranged above the ink basin 1. During operation, the ink transfer roller 21 is partially immersed in the ink in the ink basin 1, and the ink transfer roller 21 is driven to rotate by a rotating mechanism. In this embodiment, the ink transfer roller 21 The rotating mechanism includes a motor 211, and the motor 211 drives the ink transfer roller 21 to rotate and ink through the universal coupling 212 and the transmission gear mechanism, and transfer the ink to the printing plate roller. Preferably, the ink transfer roller mechanism passes through a turning mechanism Set above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com