Transfer printing and coding equipment

A pad printing and equipment technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of low pad printing efficiency, unreasonable structural design, poor pad printing definition, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

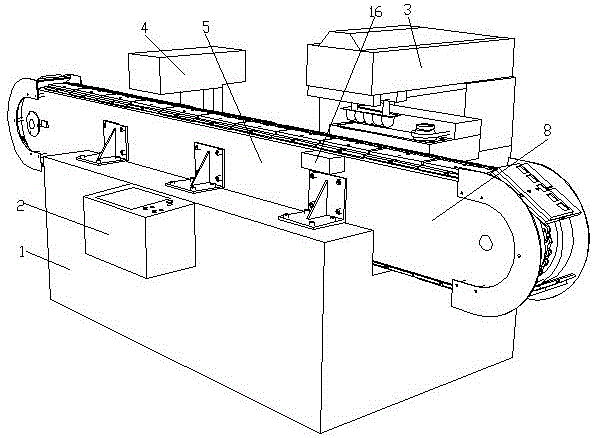

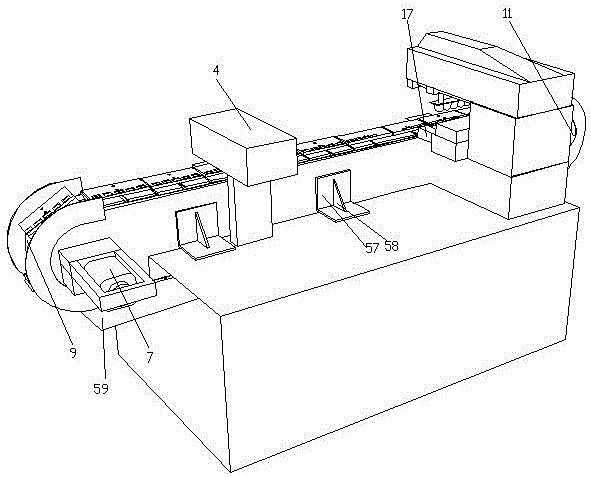

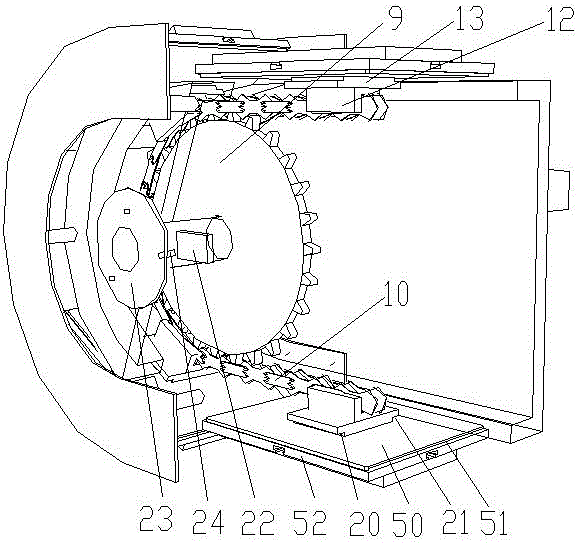

[0041] A pad printing and coding equipment, including a workbench 1, a PLC controller 2 and a pad printer 3 arranged on the workbench 1, and a laser coding machine 4 and a conveying part 5 arranged on the workbench 1, so The conveying part 5 includes a motor 7, a transmission case 8 and a main sprocket 9, a chain 10 and a secondary sprocket 11 located in the transmission case 8, the main sprocket 9 is connected with the motor 7, and the secondary sprocket 11 is connected to the main chain through the chain 10 The wheel 9 is connected by transmission. The chain 10 is fixed with a plurality of fixed seats 12, the fixed seats 12 are connected with a positioning block 13, the positioning block 13 is connected with a bracket 14, and the bracket 14 is provided with a mold groove 15. The bracket 14 is located on the surface of the transmission box 8; the side wall of the transmission box 8 is provided with a pad printing positioning piece, and the pad printing positioning piece includ...

Embodiment 2

[0044] A pad printing and coding equipment, including a workbench 1, a PLC controller 2 and a pad printer 3 arranged on the workbench 1, and a laser coding machine 4 and a conveying part 5 arranged on the workbench 1, so The conveying part 5 includes a motor 7, a transmission case 8 and a main sprocket 9, a chain 10 and a secondary sprocket 11 located in the transmission case 8, the main sprocket 9 is connected with the motor 7, and the secondary sprocket 11 is connected to the main chain through the chain 10 The wheel 9 is connected by transmission. The chain 10 is fixed with a plurality of fixed seats 12, the fixed seats 12 are connected with a positioning block 13, the positioning block 13 is connected with a bracket 14, and the bracket 14 is provided with a mold groove 15. The bracket 14 is located on the surface of the transmission box 8; the side wall of the transmission box 8 is provided with a pad printing positioning piece, and the pad printing positioning piece includ...

Embodiment 3

[0050] A pad printing and coding equipment, including a workbench 1, a PLC controller 2 and a pad printer 3 arranged on the workbench 1, and a laser coding machine 4 and a conveying part 5 arranged on the workbench 1, so The conveying part 5 includes a motor 7, a transmission case 8 and a main sprocket 9, a chain 10 and a secondary sprocket 11 located in the transmission case 8, the main sprocket 9 is connected with the motor 7, and the secondary sprocket 11 is connected to the main chain through the chain 10 The wheel 9 is connected by transmission. The chain 10 is fixed with a plurality of fixed seats 12, the fixed seats 12 are connected with a positioning block 13, the positioning block 13 is connected with a bracket 14, and the bracket 14 is provided with a mold groove 15. The bracket 14 is located on the surface of the transmission box 8; the side wall of the transmission box 8 is provided with a pad printing positioning piece, and the pad printing positioning piece includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com